Are you searching for AAC block manufacturing machine price to start or expand your building material business? As a leading AAC (Autoclaved Aerated Concrete) block production line manufacturer with 20+ years of experience, we’re here to provide transparent pricing, reliable equipment, and turnkey solutions tailored to your needs. This guide breaks down the cost of AAC block manufacturing machines by plant size, explains key pricing factors, and shows why partnering with us is the smart choice for long-term success.

AAC Block Manufacturing Machine Price: By Plant Size & Capacity

The AAC Block Manufacturing Machine price depends primarily on production capacity, automation level, and configuration. Below is our 2025 updated price range for three core plant types—designed to fit different business scales and investment budgets:

| Plant Type | Capacity Range (CBM/Year) | Setup Cost Range (USD) | Best For |

|---|---|---|---|

| Mini AAC Plant | 30,000 – 100,000 | 100,000 – 1,000,000 | New investors, small businesses, local markets |

| Medium AAC Plant | 100,000 – 200,000 | 1,200,000 – 2,300,000 | Growing enterprises, regional supply chains |

| Large AAC Plant | 200,000 – 600,000+ | 2,000,000 – 3,000,000+ | National distributors, high-volume production |

Key Notes About Pricing:

- The above ranges include core equipment (crushers, mixers, molds, cutting machines, autoclaves), installation, and basic training.

- Custom configurations (e.g., fully automatic vs. semi-automatic, additional packaging lines) may adjust the final price.

- We offer flexible payment terms for new investors to reduce initial financial pressure.

Why Do AAC Block Manufacturing Machine Prices Vary?

Understanding the factors behind AAC Block Manufacturing Machine Price helps you make an informed decision—here’s what impacts the cost of your AAC production line:

1. Production Capacity & Automation

- Mini plants (30k-100k CBM/year): Semi-automatic operation, compact design, and lower energy consumption make them ideal for startups. The price is budget-friendly, with quick ROI (12-18 months for most clients).

- Large plants (200k+ CBM/year): Fully automatic systems with PLC control, high-speed cutting machines, and industrial-grade autoclaves. They require higher upfront investment but deliver 3x higher efficiency and lower labor costs.

2. Equipment Quality & Durability

- We use premium steel and imported components (e.g., Siemens motors, Schneider electrical parts) to ensure 10+ years of stable operation. Cheap alternatives may cut costs by 20-30% but often face frequent breakdowns—costing you more in downtime and repairs.

- Our machines are certified by ISO 9001 and CE, meeting international quality standards for global markets.

3. Turnkey Services Included

- Unlike competitors who charge extra for installation and training, our prices cover:

- On-site installation and commissioning by professional engineers.

- Operator training (1-2 weeks) to master production processes.

- 1-year warranty on all core parts + lifetime technical support.

- This “all-in-one” approach saves you 15-20% in additional service fees.

Why Choose Us for Your AAC Block Manufacturing Machine?

We don’t just sell equipment—we partner with you to build a profitable AAC block business. Here’s why 500+ clients in 30+ countries trust us:

1. Transparent Pricing, No Hidden Fees

We provide detailed quotes that list every component and service—no surprise charges after signing the contract. For mini plants, we even offer a “basic package” to help startups get started with minimal investment.

2. High-Quality Machines with Proven ROI

Our AAC production lines have a 98% uptime rate and reduce raw material waste by 10% (vs. industry average). Clients report recouping their investment in 12-24 months, thanks to efficient production and low maintenance costs.

3. Custom Solutions for Your Market

Whether you’re targeting local construction companies or exporting AAC blocks, we tailor the plant to your needs:

- Adjust block sizes (600x200x100mm, 600x240x200mm, etc.) to match regional building standards.

- Add eco-friendly features (e.g., waste heat recovery systems) to reduce energy costs by 25%.

4. 24/7 Global Support

Our technical team responds within 12 hours to service requests. We also have local service centers in Asia, Africa, and Europe to provide on-site support quickly—no waiting weeks for engineers to arrive.

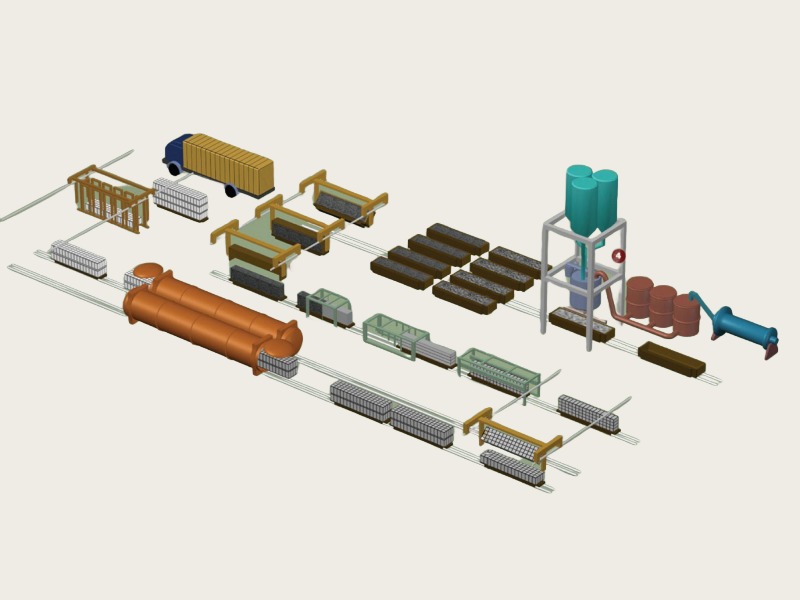

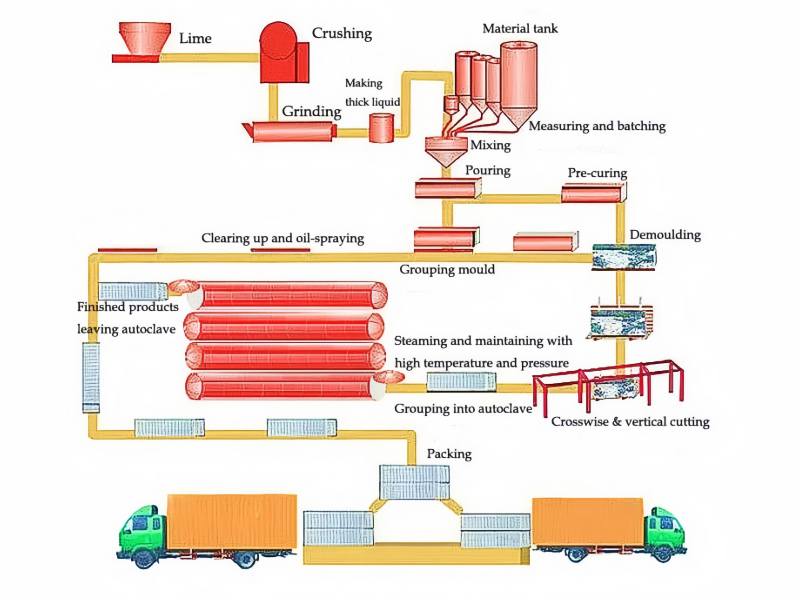

AAC Block Plant Process

Raw material process → Batching and Mixing → Pouring → Static pre-curing → Cutting → Autoclaving Curing → Finished product Processing

1. Raw Material Processing: Sand is crushed and ground to the desired fineness. Cement, lime, and gypsum are stored in silos, and aluminum powder is mixed with water to form an aluminum slurry.

2. Batching and Mixing: The various raw materials are weighed according to precise proportions and then thoroughly mixed in a mixer to form a uniform slurry.

3. Pouring: The mixed slurry is poured into steel molds. The size and shape of the molds can be designed to meet the desired block specifications.

4. Static Pre-curing: The molds containing the slurry are transported to a pre-curing area where the slurry gradually hardens under suitable temperature and humidity conditions to achieve initial strength. This process typically takes several hours.

5. Cutting: After the slurry is pre-cured, it is cut into the desired size and shape using high-precision cutting equipment using steel wire or blades.

6. Autoclave Curing: Blocks are placed in an autoclave and cured for several hours at temperatures of 175-200°C and pressures of 10-15 bar, significantly enhancing the blocks’ strength and durability.

7. Finished Product Processing: After autoclave curing, the blocks are removed from the autoclave and transported to a storage area. After inspection and packaging, they are ready for shipment.

Why Invest in The AAC Block Manufacturing Machine?

The cost of a small AAC production line varies widely and depends on several factors. Generally speaking, the total investment for a small AAC production line with an annual capacity of 300,000-100,000 cubic meters ranges from $250,000 to $800,000.

1. Low equipment price, but comparable technology to European standards.

For the same 300,000 m³/year complete line, European quotes range from $2.8 million to $3.2 million, while ours can deliver for $1.9 million to $2.2 million.

Cutting accuracy of ±1 mm, autoclave waste heat recovery, and fully automated robotic palletizing, all based on authorized German drawings.

2. High production capacity flexibility

Modular design: For example, Initially launch with 100,000 m³/year to validate the market, seamlessly expand to 300,000 m³ within 6 months, with additional investment less than 40% of the original cost.

No production interruption during the upgrade, ensuring continuous cash flow.

3. Fastest Payback

With an average selling price of $85/m³ and 70% capacity utilization, a 200,000 m³/year plant can achieve a payback period of 18–22 months.

4. Perfect After-Sales Service

24/7 remote diagnostics and 48-hour on-site overseas engineer service.

Lifetime price lock for spare parts, ensuring worry-free maintenance.

Application of AAC Block

Civil Buildings: Used in internal and external walls, floor slabs, roof slabs, etc. of residential buildings to reduce building weight and improve seismic performance.

Commercial Buildings: Suitable for non-load-bearing walls of shopping malls, hotels, office buildings, etc., with good thermal insulation and sound insulation effects to enhance building comfort.

Industrial Buildings: Served as wall and partition materials for factories and warehouses, meeting the special requirements of industrial production for building materials.

Special Buildings: Widely applied in hospitals, schools, gymnasiums and other places due to their excellent fire resistance and environmental protection properties.

Mini AAC blokli zavod quvvati

| Qolib hajmi (L × W × H) | Kunlik ishlab chiqarish (m³) | Yillik ishlab chiqarish (m³) | Zamin maydoni | Avtoklav spetsifikatsiyasi |

| 2,0 × 1,2 × 0,6 m | 100 - 150 | 30 000 - 45 000 | 4 000 – 5 000 ㎡ | 2 dona PH2,0 × 31,5 m |

| 4,2 × 1,2 × 0,6 m | 160 - 220 | 50 000 - 70 000 | 5 000 – 6 500 ㎡ | PH2,5 × 32 m va undan yuqori o'lchamdagi 2 birlik |

How to Find a High-Quality Manufacturer at a Lower Price

Define your requirements:

Identify production capacity, raw materials, and automation level.

Request a sub-item quote+modular solution:

Request prices for the cutting line, autoclave, dust removal, and electronic control components individually. This can yield a 10-15% price difference.

It’s possible to install core modules first and expand capacity later to avoid a large, one-time investment.

Site Inspection+Demonstration Projects:

Visit at least two AAC production lines of the same scale that have been operating for at least two years, focusing on failure rates, energy consumption, and yield rates.

Strive for package financing

Ask the manufacturer if a export credit+financial leasing package is possible, with a down payment of 20% and interest rates 2–3 percentage points lower than commercial banks.

AAC block Plant ROI

| Plant size | Annual revenue* | Annual profit* | Pay-back |

| 100 000 m³ | US$6.0 – 8.0 M | US$1.2 – 2.0 M | 2.0 – 2.5 yr |

| 200 000 m³ | US$12 – 16 M | US$2.8 – 4.0 M | 1.8 – 2.2 yr |

| 400 000 m³ | US$24 – 32 M | US$6.0 – 8.0 M | 1.5 – 1.8 yr |

Note: Based on average selling price US$75–100 /m³ and 70 % capacity utilization.

Ready to Custom AAC Block Manufacturing Machine?

The prices above are general guidelines—your exact cost depends on your production goals, local market needs, and custom requirements. To get a free, personalized quote (with no obligation), simply:

- Fill out our online inquiry form with your desired capacity and location.

- Our sales team will analyze your needs and send a detailed quote within 24 hours.

- We’ll also share case studies of clients in your region—so you can see how our machines perform in real-world scenarios.