AAC Plant Exported to Poland with 150,000 m³/Year

In June 2025, we successfully exported and installed a 150,000 m³/year medium-size AAC block plant to Poland.

Plant Type: Medium AAC Plant — 150,000 m³/year

Setup Cost Range: USD 1,200,000 – 2,300,000 (equipment + installation)

Country: Poland

Customer Profile: A mid-sized developer expanding into AAC manufacturing to reduce material cost and create a regional supply chain.

Scope of Supply:

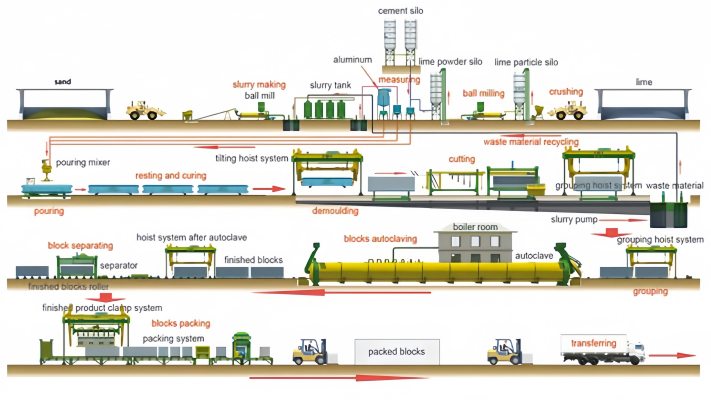

- Raw material batching & mixing system

- Moulds & tilting system

- Automatic cutting line

- 8× autoclaves

- Boiler & steam distribution

- Packing & stacking line

- On-site installation + commissioning

- Polish operator training program

What Is an AAC Block Production Line?

An AAC (Autoclaved Aerated Concrete) production line is a fully automated plant used to produce:

- AAC blocks

- لوحات AAC

- Lightweight partition blocks

It involves mixing → pouring → pre-curing → cutting → autoclaving → packing.

Key advantages of AAC blocks:

- Up to 70% lighter than concrete

- Excellent thermal insulation (suitable for Poland’s cold winters)

- Fire resistance up to 4 hours

- Easy handling and installation

- Lower overall construction cost

Advantages of AAC Plant Exported to Poland

✔ 1. European Standard Quality (CE-Compliant)

All major systems comply with EU machinery standards, ensuring smooth import, easy certification, and long-term reliability.

✔ 2. Fully Automatic Cutting—±1 mm Accuracy

Our vertical + horizontal cutting system guarantees premium surface precision and reduces wastage.

✔ 3. Energy-Saving Autoclave System

Optimized steam routing reduces:

- Energy consumption by 12–18%

- Production cost per m³

- Pressure fluctuation during curing

✔ 4. Suitable Capacity for Poland’s Market

150,000 m³/year allows the investor to:

- Supply multiple cities (Warsaw, Kraków, Gdańsk)

- Avoid overproduction risk

- Maintain high profitability

✔ 5. One-Stop Turnkey Service

From plant design to installation and after-sales support, the customer only needed one supplier.

Before & After: Results for the Polish Customer

Before starting the plant:

- Depended on imported AAC blocks

- High transportation costs

- Unstable supply

- Longer delivery time for construction projects

After installing the 150,000 m³ plant:

- Local production reduced cost by 35%

- Continuous supply improved project timelines

- Gained 14+ regional distributors

- Achieved capacity utilization of 82% in the first year

Looking to Build an AAC Block Manufacturing Plant?

Whether you need:

- A 50,000–600,000 m³/year AAC block manufacturing plant

- Customized block densities

- Fully automatic or semi-automatic configurations

- Turnkey engineering support

- Cost estimation for a new AAC factory

We can provide a complete solution.

👉 Contact us today for a free feasibility report and quotation.

Our engineering team will design the best AAC block solution for your market.