150,000 m³/Year AAC Block Plant Exported to Sweden

Our company successfully exported a 150,000 m³/Year AAC Block Plant to Sweden.

- Annual Capacity: 150,000 m³/year

- Setup Cost Range: USD 1,200,000 – USD 2,300,000

- Automation Level: Fully automatic with Siemens PLC

- Production Standard: CE-compliant, energy-saving steam curing system

- Application Range:

- Residential low-rise and mid-rise buildings

- Green construction materials

- Lightweight thermal-insulation AAC panels & blocks

Plant Size Selected for Sweden

Sweden’s domestic AAC consumption is growing but still moderate. Based on market data and the customer’s sales forecast, we recommended a Medium AAC Plant.

✅ 150,000 m³/year AAC Block Plant (Medium Scale)

Reason for Choosing Medium Scale:

- Matches Sweden’s mid-sized construction market

- Ideal for supplying Stockholm—Uppsala—Västerås region

- Easier logistics and short delivery times

- Lower initial investment burden

- Shorter payback period (estimated 2.8–3.5 years)

On-Site Installation & Commissioning in Sweden

Installation Scope:

- Batching system assembly

- Autoclave installation & testing

- Cutting line alignment

- Electrical wiring

- Air compressor system setup

- Steam system integration

Commissioning Results:

- First successful trial run: June 28, 2025

- First batch of AAC blocks produced: June 30, 2025

- Output achieved 96% of target within 2 weeks

- Cutting accuracy and autoclave performance exceeded expectations

Staff Training Included:

✔ Machine operation training

✔ Maintenance training

✔ Safety procedures

✔ Automation & PLC usage

✔ Quality control (density, strength, curing)

Key Advantages of AAC Block Plant Exported to Sweden

1. High Automation Reducing Labor Cost

Labor cost in Sweden is high, so automation is essential.

Our system supports:

- One-click batch control

- Automatic mold circulation

- No manual cutting

- Automatic grouping & packaging

The plant requires only 12–14 workers per shift, saving long-term labor costs.

2. European-Level Precision

- Cutting tolerance: ±1.5 mm

- Smooth edges

- Consistent density

- Stable quality even during high-output cycles

3. Energy Efficiency Designed for Northern Climate

We tailored the steam and insulation design to reduce heat loss in colder months.

4. Easy Operation & Maintenance

The PLC system automatically monitors:

- Steam pressure

- Mixer load

- Autoclave cycles

- Cutting system alignment

Maintenance reminders are included.

5. Full After-Sales Service

- Remote PLC support

- 24/7 technical assistance

- Spare parts stocked in EU warehouse (Belgium)

Complete Equipment Configuration Shipped to Sweden

To meet EU quality requirements, the Swedish customer ordered an upgraded configuration.

1. AAC Raw Material Batching & Mixing System

- Automatic cement + lime dosing

- Fly ash slurry mixing tank

- Aluminum powder feeding

- PLC controlled batching

2. Moulds & Side Plates (European Standard Steel)

- Reinforced, anti-deformation moulds

- Precision machined side plates

- Suitable for 600×200×100/125/150 mm blocks

3. Cutting System (High Precision)

- Vertical cutting machine

- Horizontal cutting machine

- Swing-cut equipment

- Automatic waste removal & recycling

Cutting error remains within ±1.5 mm, meeting Scandinavian industry standards.

4. Autoclave Section

- 8 autoclaves, 2.68 m diameter, 36 m length

- Internal stainless steel safety mesh

- European CE-compliant valves and gauges

- Automatic steam control

5. Final Product Handling System

- Tilting table

- Grouping machine

- Palletizing station

- Packing system

6. Smart Automation Controls

- Siemens PLC

- Remote monitoring

- Real-time production dashboard

- Automated alarm and safety interlocks

Energy-Saving Enhancements for Northern Europe

- 15% lower steam consumption

- Thermal insulation upgrade

- Heat recovery system

- Low-noise cutting station

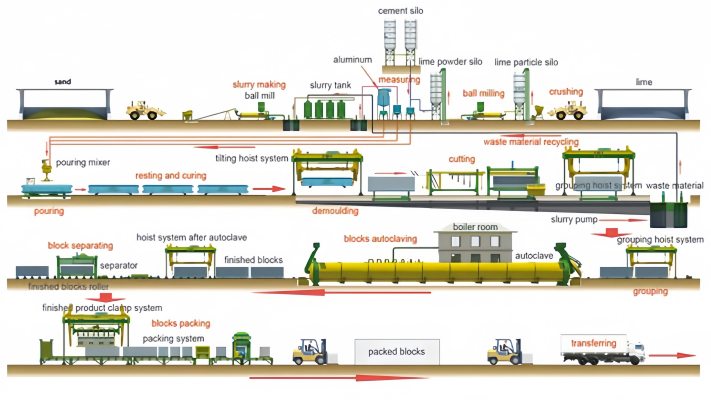

Complete Production Process

- Sand processing & grinding

- Slurry mixing

- Mold casting

- Pre-curing

- Tilting & demolding

- Horizontal & vertical precision cutting

- Grouping & autoclaving

- Steam curing cycle

- Final inspection

- Automated packaging & palletizing

Our engineers ensured stable production from day one.

Why Choose Us?

✔ 20+ Years of Manufacturing Experience

✔ Exported to 80+ Countries Worldwide

✔ CE-Compliant Components for Europe

✔ Faster Delivery Than European Suppliers

✔ Strong After-Sales & Engineering Team

✔ Lower Investment + High ROI

Start Your AAC Block Manufacturing Plant?

This successful 150,000 m³/year AAC Block Plant exported to Sweden demonstrates that we can meet the strict technical, environmental, and performance standards required in Northern Europe.

Whether you need:

- AAC block machine

- AAC block production line

- Turnkey AAC plant design

- Autoclaved aerated concrete manufacturing solution

…we can provide a professional, cost-effective, global-standard solution.

📩 Contact us today for a plant design, cost estimation, or feasibility report.

Typical FAQs from Swedish AAC Investors

Medium plants (100,000–200,000 m³/year) are ideal for Sweden’s market size.

400V, 50Hz three-phase, fully compatible with EU standards.

Yes, we provide CAD layout + civil foundation drawings.

Normally 45–60 days.

D400, D500, D600 with compressive strength of 3.5–5.5 MPa.