150,000 m³/Year Завод по производству блоков AAC для Франции

Как профессионал AAC block manufacturing plant supplier with 20+ years of experience and exports to 80+ countries, we completed another turnkey project in Europe — a 150,000 CBM/year Medium-Scale AAC Block Plant for France.

✔ Project Overview

| Country | France |

| Production Line Type | Medium AAC Block Plant |

| Annual Capacity | 150,000 CBM/year |

| Investment Range | USD 1.2M – 2.3M |

| Приложение | Residential housing, apartments, schools, energy-efficient buildings |

| Уровень автоматизации | 80% automatic |

| Warranty & Support | 1-year warranty, lifetime technical support |

AAC Block Sizes Required by the French Market

During the design phase, the customer requested custom block dimensions that match French building standards:

- 600 × 200 × 100 mm

- 600 × 200 × 150 mm

- 600 × 200 × 200 mm

- Custom thicknesses up to 300 mm

Our cutting system maintains ±1 mm dimensional accuracy, meeting European building code requirements.

Why the French Customer Chose Our AAC Block Plant?

After comparing multiple suppliers from China and Europe, the France buyer finally selected us because of the following advantages:

1. 20+ Years of Manufacturing Experience

We specialize in designing and manufacturing AAC production lines, offering stable equipment, proven technology, and high-precision cutting systems.

2. Perfect Cost–Performance Ratio for the European Market

While many European machines are overpriced, our solution offers:

- lower investment,

- optimized energy consumption,

- European-standard components (Siemens, Schneider, ABB, etc.).

3. Fully Automated Cutting & Handling

This significantly reduces labor costs — a major concern in France.

4. Professional On-Site Installation in France

We sent:

- two mechanical engineers,

- one electrical engineer,

- and one commissioning expert

to guide assembly and ensure full compliance with French safety regulations.

5. Local Climate & Raw Material Adaptation

We helped the client optimize:

- lime formula,

- aeration performance,

- autoclave curing cycle,

based on local raw materials in southern France.

Full Scope of AAC Block Plant for France

Main Equipment Supplied

- Щековая дробилка

- Ball Mill & Slurry Preparation System

- Automatic Batching & Mixing System

- Moulds & Side Plates

- Wire Cutting Machine (Vertical + Horizontal)

- Grouping & De-moulding System

- Autoclaves (2 units, 36m)

- Паровой котел

- Packing Line with Automatic Palletizing

Additional Services Provided

- Factory layout design (3D + 2D)

- Electrical system & cable layout

- Foundation drawings

- Operating training for French workers

- Spare parts for 2 years

Installation & Commissioning Process in France

1. Equipment Arrival & Unloading — July 2024

Сайт machines arrived at Marseille Port and were transported to the customer’s industrial site.

2. Civil Work Completion

The customer followed our foundation drawings with strict reinforcement standards for autoclave pits, rail tracks, and batching silos.

3. Mechanical Installation — July to August 2024

Our engineers guided the installation of:

- mixers

- шаровая мельница

- cutting system

- autoclaves

- boiler system

4. Electrical Installation — August 2024

Our electrical engineer worked with local electricians to:

- wire all control cabinets,

- connect PLC systems,

- test safety interlocks.

5. Trial Production — September 2024

The first batch of AAC blocks passed all quality tests for:

- density,

- compressive strength,

- moisture content,

- block size accuracy.

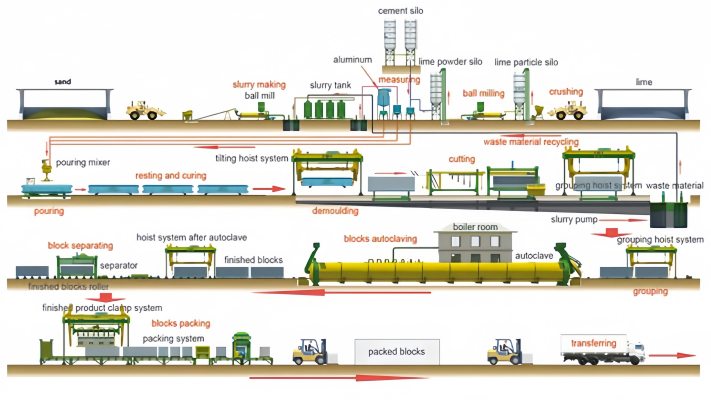

Complete Production Process

- Sand processing & grinding

- Slurry mixing

- Mold casting

- Предварительное отверждение

- Tilting & demolding

- Horizontal & vertical precision cutting

- Grouping & autoclaving

- Steam curing cycle

- Final inspection

- Automated packaging & palletizing

Our engineers ensured stable production from day one.

Key Results Achieved

1. Stable Output: 450–500 CBM/day

Matches the targeted annual capacity of 150,000 CBM.

2. 30–35% Reduction in Labor Cost

The automation system replaced several manual operations.

3. 20% Lower Energy Consumption

Optimized boiler system + precise batching reduced steam usage.

4. Perfectly Compatible with French Construction Standards

AAC blocks produced meet:

- NF EN 771-4

- European AAC performance requirements

What Our Client Says?

“We are extremely satisfied with both the equipment performance and your technical service.”

Почему выбирают нас?

✔ European-Standard Electrical Components

(Siemens PLC, Schneider switches, ABB motors)

✔ Enhancing automation to reduce European labor dependency

✔ Tight tolerances in block size (±1 mm)

Essential for France, Germany, UK, Sweden, Netherlands.

✔ On-site installation & lifetime support

✔ 3D customized plant layout

Start Your AAC Block Manufacturing Plant?

If you are planning to set up an AAC block factory in France or anywhere in Europe, we can provide:

- Full feasibility study

- Cost calculation

- Production configuration

- Customized factory layout

- On-site installation service

📩 Contact us now to get the latest price & technical proposal.

We reply within 12 hours.

Frequently Asked Questions for Buyers in France

A medium AAC plant (100,000–200,000 CBM/year) is ideal for regional supply.

Approximately 60–90 days depending on civil work readiness.

A 150,000 CBM/year line costs USD 1.2M – 2.3M depending on configuration.

Yes, we regularly send engineers to Europe for installation and maintenance.

Absolutely — CE-compliant safety systems are available.