200,000 m3/Year AAC Block Plant Manufacturer and Supplier

The 200,000 m³/Year AAC Block Plant is a high-capacity large-scale production line, specialized in Autoclaved Aerated Concrete (AAC) blocks, with an annual output of 200,000 m³.

Our plant can be fully customized according to your specific production requirements, local raw material characteristics and site conditions.

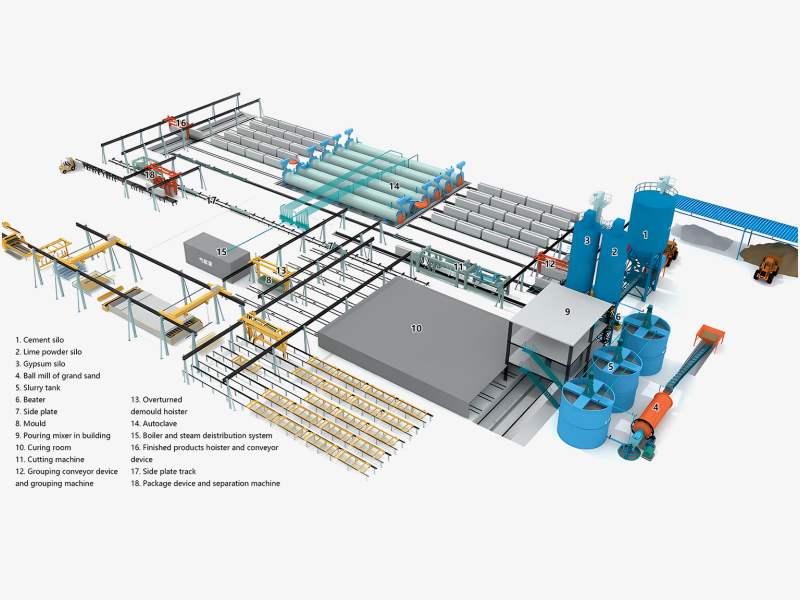

Its main equipment includes high-precision raw material batching system, efficient mixing-pouring machine, CNC precision cutting machine, large-capacity autoclave, intelligent conveying system and automatic packaging system, etc.

- Capacity: 200,000m3/year

- Type: Fully automatic

- Used for: Producing standard-sized AAC blocks, plus AAC wall panels, load-bearing lintels and composite floor slabs.

.

200,000 m3/Year AAC Block Plant Price

The total price of 200,000 m3/Year AAC Block Plant ranges from $1,000,000 to $3,5 00,000 (excluding land costs). The main factors affecting the price are: equipment configuration, customization requirements, brand and manufacturer reputation, after-sales service, etc.

1. Equipment Configuration

- Manual batching systems: Lower cost (fits lower price range).

- Automated computer-controlled batching: Higher cost (ensures quality, pushes price up).

- Smaller autoclaves (e.g., 100 m³) & weak mixers: Cheaper.

- Larger autoclaves (e.g., 150 m³) & strong mixers: More expensive (for higher output).

2. Customization

- Non-standard block sizes (needs special molds/cutting tweaks) or more AAC wall panels (line rework): Adds cost.

- Special gear for local raw materials (e.g., high-moisture sand) or site limits (space, noise/dust rules): Increases cost.

3. Brand/Manufacturer

- Established brands: Pricier (proven quality, good after-sales, long warranties/training).

- New brands: Cheaper (no strong track record).

- Imported (German/Japanese): More expensive (plus shipping, duties, currency fees).

4. After-Sales Services

- Longer warranty (3-5 years vs. 1-2 years) or full coverage (on-site repairs): Raises price.

- On-site/online training, regular checks, fast spare parts: Adds cost (keeps plant running smoothly).

Advantages of 200,000 m3/Year AAC Block Plant

High Capacity for Big Orders:

Annual output of 200,000 m³ fits large needs (high-rises, commercial projects, material bases). No production delays—easy to take bulk orders and grow market share.

Efficient Production Cuts Unit Cost:

- Automated Systems: Computer-controlled batching and smart conveying reduce mistakes and speed up work (15%-20% shorter cycles than small plants).

- Scale Benefits: More output spreads fixed costs (depreciation, labor), lowering unit cost of AAC products by 10%-12%.

Versatile Products Boost Earnings:

Makes not just standard AAC blocks, but also wall panels, lintels, and floor slabs. Meets different customer needs (residential/industrial/commercial) and taps into high-value markets.

Stable Quality Builds Trust

- Precision Gear: High-accuracy batching and CNC cutting ensure consistent size (error ±1mm) and strength (3.5-7.5 MPa), meeting global standards (ASTM C1386, EN 771-4).

- Steady Curing: Large autoclaves keep temperature/pressure stable—every batch has the same good performance (thermal insulation, fire resistance).

200,000 m3/Year AAC Block Plant Process

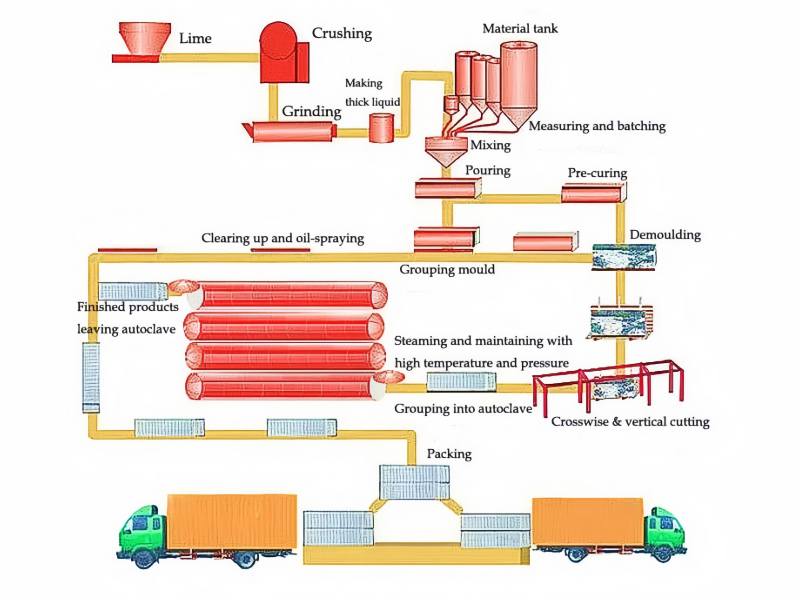

Raw material process → Batching and Mixing → Pouring → Static pre-curing → Cutting → Autoclaving Curing → Finished product Processing

1. Raw Material Processing: Sand is crushed and ground to the desired fineness. Cement, lime, and gypsum are stored in silos, and aluminum powder is mixed with water to form an aluminum slurry.

2. Batching and Mixing: The various raw materials are weighed according to precise proportions and then thoroughly mixed in a mixer to form a uniform slurry.

3. Pouring: The mixed slurry is poured into steel molds. The size and shape of the molds can be designed to meet the desired block specifications.

4. Static Pre-curing: The molds containing the slurry are transported to a pre-curing area where the slurry gradually hardens under suitable temperature and humidity conditions to achieve initial strength. This process typically takes several hours.

5. Cutting: After the slurry is pre-cured, it is cut into the desired size and shape using high-precision cutting equipment like steel wire or blades.

6. Autoclave Curing: Blocks are placed in an autoclave and cured for several hours at temperatures of 175-200°C and pressures of 10-15 bar, significantly enhancing the blocks’ strength and durability.

7. Finished Product Processing: After autoclave curing, the blocks are removed from the autoclave and transported to a storage area. After inspection and packaging, they are ready for shipment.

Raw Materials of AAC block

- Cement (Portland Cement): Acts as a primary binder, providing strength and durability to the blocks. Typically, 43 or 53-grade OPC is used.

- Fly Ash or Sand: Serves as the main siliceous material. Fly ash, a byproduct of coal-fired power plants, is an eco-friendly alternative to sand, providing the necessary silica content.

- Lime: A key calcareous material that reacts with other components to form the binding matrix and contributes to the chemical reactions during production.

- Gypsum: Added in small quantities to regulate the setting time and improve the workability of the mix.

- Aluminum Powder or Paste: Functions as a foaming agent. It reacts with lime and water to produce hydrogen gas, creating the characteristic porous, lightweight structure.

- Suv: Essential for the hydration of cement and lime, and to facilitate the chemical reactions necessary for the setting and hardening of the blocks.

These materials are carefully proportioned and mixed to form a slurry, which is then cast, pre-cured, cut, and finally autoclaved to produce the finished AAC blocks.

Main Equipment in 200,000 m3/Year AAC Block Line

1. Jaw Crusher

Function: Crushes large lumps of raw materials such as limestone and gypsum into 50-150 mm pieces, facilitating subsequent fine grinding. It is a key piece of equipment for raw material pretreatment.

Structure: A fixed jaw plate and a movable jaw plate form a deep-chamber crushing chamber lined with impact-resistant, replaceable high-manganese steel tooth plates.

Capacity Range: Common models range from 100 to 500 t/h. The motor and main unit are integrated on a steel frame base, occupying only 4-6 m² of floor space.

2. Ball Mill

Function: Grinds crushed lime, sand, or fly ash into a fine powder with a mesh size of 80-400 (0.2-0.045 mm) to enhance reactivity.

Structure: Horizontal cylinder+wear-resistant liner+steel ball media. It driven by a motor, reducer, and large gear.

Key Parameters: Cylinder diameter 1.2-2.4 m, ball load 5-30 t, power 55-800 kW.

3. Batching System

Function: Accurately weighs cement, lime, fly ash, aluminum powder, and water according to the recipe, with an error of ≤ ±0.5%. Equipped with multiple silos, metering, and conveying equipment.

Module components: Electronic scale, screw feeder, pneumatic butterfly valve, PLC touch screen; one-touch recipe call, batching completed within 30 seconds.

4. Mixing & Casting Machine

Function: Rapidly mixes weighed dry materials with water and aluminum powder into a fluid slurry, which is then poured into a mold for foaming.

Features: Twin-shaft forced mixing completes one batch in 60-90 seconds; hydraulically tilts 90° for drip-free pouring.

Key Parameters: Effective volume 2-4 m³, motor power 37-55 kW, removable mixing blades, wear life ≥ 30,000 cycles.

5. Tilting Cutter

Function: Cuts pre-cured billets into desired specifications with an accuracy of ±1 mm. Offcuts are recycled online.

Structure: Three sets of longitudinal, transverse, and horizontal steel wire frames; servo motors synchronize lifting and lowering, automatically compensating for wire wear.

Capacity: Cutting cycle ≤ 5 minutes/die; can cut 75-300 mm thickness, 600 mm standard length, or 1200 mm slabs.

6. Autoclave

Function: High-temperature, high-pressure steam curing allows the green body to complete the hydrothermal synthesis reaction within 8 hours, increasing its strength by 5-8 times.

Specifications: Φ2.68×32 m or Φ2.85×38 m; design pressure 1.6 MPa, operating temperature 200°C; equipped with safety interlock and automatic blowdown.

Configuration: Each medium-sized line is equipped with 4-8 units, which can be connected in series or parallel. Energy-saving models include a waste heat recovery interface.

7. PLC Control Room

Function: Serves as the control center for the entire production line, offering features such as recipe management, parameter adjustment, process monitoring, energy consumption analysis, fault alarms, and remote app viewing.

Hardware: Reserved OPC UA interface for integration with the factory’s MES/ERP system.

8. Waste Gas Heat Recovery System

Principle: Autoclave exhaust gas at 160°C is preheated to 90°C via a heat exchanger, saving 8–12% of natural gas annually.

Configuration: Plate heat exchanger+circulation pump+automatic temperature control valve.

Main Parameters of 200,000 m³ AAC bloklari zavodi

| Parameter Category | Specific Parameter | Details |

| Basic Capacity | Annual Output | 200,000 m³ (based on standard AAC block size: 600×240×100mm) |

| Daily Output (Working Days: 300) | About 667 m³/day | |

| Core Equipment Specs | Raw Material Batching System | Capacity: 8-12 m³/h; Accuracy: ±0.8% (for cement, lime, fly ash) |

| Mixing-Pouring Machine | Mixing Capacity: 5-7 m³/batch; Pouring Speed: 3-4 batches/h | |

| CNC Cutting Machine | Cutting Size Range: based on your need | |

| Avtoklav | Quantity: 4-6 units; Single Volume: 100-150 m³; Working Pressure: 1.2-1.5 MPa | |

| Conveying System | Speed: 2-2.5 m/s; Material: Carbon steel (double anti-rust treatment) | |

| Product Specifications | Main Product Types | Standard AAC blocks, AAC wall panels (max length: 8m), load-bearing lintels, composite floor slabs |

| Product Performance | Compressive Strength: 3.5-7.5 MPa; Dry Density: 500-700 kg/m³ | |

| Issiqlik izolyatsiyasi | Thermal Conductivity: 0.12-0.15 W/(m·K) | |

| Energy & Operation | Fuel Consumption | About 7-9 kg standard coal/m³ AAC product (with advanced waste heat recovery) |

| Power Consumption | About 45-55 kWh/m³ AAC product | |

| Labor Requirement | 10-14 workers per shift (3 shifts/day for continuous operation) | |

| Site & Layout | Required Factory Area | About 20,000-25,000 m² (including raw material storage, production area, finished product warehouse, auxiliary facilities) |

| Water Supply | About 1.5-2 m³ water/m³ AAC product (recyclable rate: ≥80%) |

What Is An AAC Block?

Autoclaved aerated concrete (AAC) blocks are a lightweight, porous, high-strength new building material.

The unique internal pore structure provides lightweight, high strength, thermal insulation, fire resistance, and sound insulation.

It is an ideal choice for achieving energy-saving and structural safety in buildings.

Nima uchun bizni tanlaysiz?

Investing in a 200,000 m³/Year AAC Block Plant is a big decision—and we’re here to make sure your investment pays off. Here’s what you get when you work with us:

1. Turnkey Solution:

We offer full turnkey service—from plant design, equipment manufacturing, to installation, commissioning, and staff training. Our engineers have over 15 years of AAC plant experience, so we’ll build the plant exactly as you need, and make sure it meets local rules.

2. After-Sales Support:

We’re here for you 24/7 with after-sales service, including:

- Regular maintenance checks (on-site or online).

- Fast spare parts supply (we keep lots of parts in key areas).

- Technical training for your operators and maintenance team (in-person or online).

3. Customization Options:

We know every customer has different needs. Whether you want to adjust the plant’s capacity, add special equipment (like a waste water recycling system), or adapt to local raw materials, we can customize the plant to fit you.

4. Proven Track Record:

We’ve supplied AAC block plants to over 50 countries (e.g., India, Indonesia, Nigeria, Brazil). Our 200,000 m³/Year AAC Block Plant works well in many projects, and customers say it hits or exceeds the annual capacity target 95% of the time.

Services We Offer

- Loyihani rejalashtirish va loyihalash

Mijozlarning ehtiyojlari va haqiqiy sharoitlarga asoslangan AAC bloklari zavodlari uchun umumiy rejalashtirish va batafsil dizayn sxemalarini taqdim eting, shu jumladan jarayonni loyihalash, uskunalarni joylashtirish va qurilish muhandislik dizayni. - Uskunalarni etkazib berish va o'rnatish

AAC ishlab chiqarish liniyasi uskunalarining to'liq to'plamini etkazib bering va normal ishlashini ta'minlash, loyihalashtirilgan quvvat va mahsulot sifati standartlariga javob berish uchun o'rnatish va ishga tushirishni amalga oshiring. - Texnik ta'lim

Operatorlar, texniklar va menejerlar uchun ishlab chiqarish jarayonlari, uskunalardan foydalanish, texnik xizmat ko'rsatish va sifatni boshqarish bo'yicha professional treninglarni taklif qiling. - Sotishdan keyingi xizmat

Uzluksiz barqaror ishlab chiqarishni ta'minlash uchun kundalik parvarishlash bo'yicha ko'rsatmalar, nosozliklarni bartaraf etish va ehtiyot qismlar bilan ta'minlash bo'yicha ishonchli sotuvdan keyingi tizimni yarating. - Texnik qo'llab-quvvatlash va yangilash

Doimiy texnik yordam ko'rsating va samaradorlik va sifatni yaxshilash uchun mijozlar ehtiyojlari va sanoat tendentsiyalariga asoslangan uskunalarni yangilash/texnik o'zgartirish echimlarini taklif qiling. - EPC Bosh pudratchi

Muammosiz tajriba uchun loyihalash, asbob-uskunalarni xarid qilish, fuqarolik qurilishi, o'rnatish va o'qitishdan tortib, sinov ishlab chiqarishgacha bir martalik EPC xizmatlari.

Other Hot-sale Block Manufacturing Plant

| Annual Production | Price (USD) | Core Configuration |

|---|---|---|

| 100,000 m³ | 1.5–1.9 M | Air-turning cutting, 3×31 m autoclaves |

| 150,000 m³ | 2.1–2.6 M | Robotic palletizing, 4×31 m autoclaves |

| 200,000 m³ | 2.8–3.5 M | Six-sided cutting, 4×37 m autoclaves |

| 300,000 m³ | 4.0–4.8 M | Dual cutting lines, 6×37 m autoclaves |

| 400,000 m³ | 5.5–6.5 M | Fully automatic air-turning, 8×37 m and above autoclaves |