AAC Block Mini Plant for Sale with Various Capabilities

AAC Block Mini Plant, or small-scale autoclaved aerated concrete block production plant, is designed for small-scale production, featuring a compact footprint, low costs, and simple installation, commissioning, and operation.

Whether for small building materials factories, rural construction projects, or applications with low-volume production requirements, it provides an efficient and cost-effective production solution.

We supply semi-automatic and fully automatic types of AAC block mini plant, each section can be customized according to your needs. We guarantee to use the best solutions and sincerely serve our customers and partners.

Capacity: <100,000 m³/year

Autoclaves: 3-4

End product: AAC Block/Aerated concrete slabs

Standard: China, ASME, EU, and others

Automation Grade: Semi-automatic, Automatic

Brick Material: Fly Ash/Sand

Brick Dimension: customized

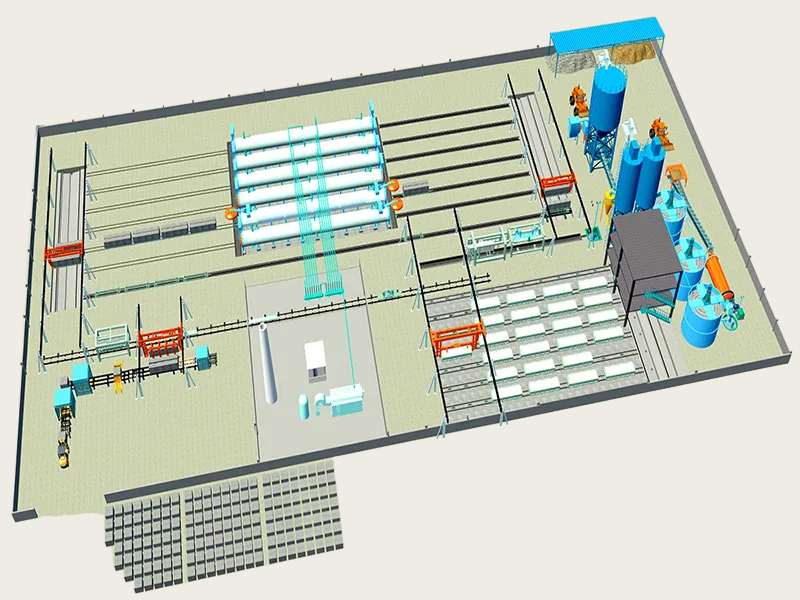

Factory area: 4000 -5000 m2

Sertifikat: ISO 9001

What is the Cost of An AAC Block Mini Plant?

The cost of an AAC Block Mini Plant varies widely and depends on several factors. Generally speaking, the total investment for a small AAC production line with an annual capacity of 300,000-100,000 cubic meters ranges from $250 000 dan $800 000 gacha.

- Hindiston / Janubi-Sharqiy Osiyoda qo'lda ishlab chiqarish liniyasi: $250 000–400 000

- Xitoyda yarim avtomatik ishlab chiqarish liniyasi: $350 000–550 000

- Evropa va Amerika Idoralar standartlari uchun to'liq avtomatlashtirilgan ishlab chiqarish liniyasi: $600 000–800 000

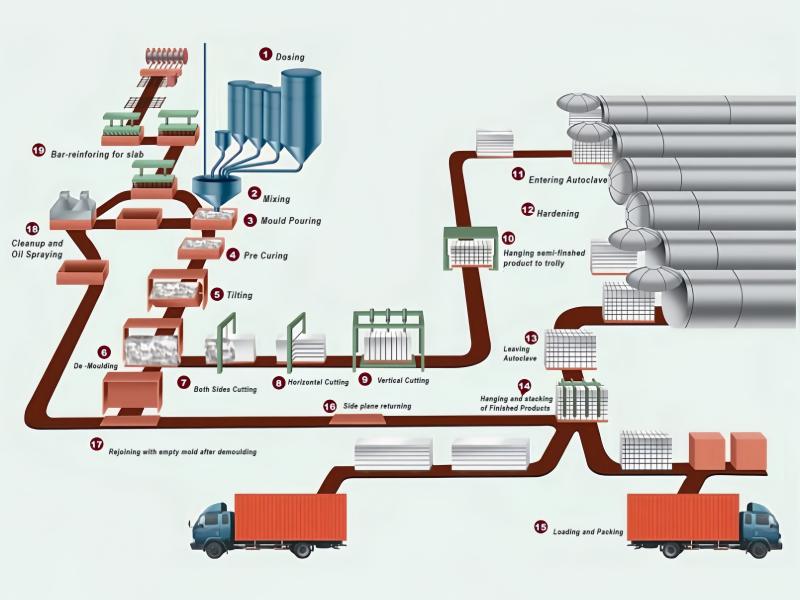

Mini AAC ishlab chiqarish jarayoni

1. Xom ashyo jarayoni

Jarayon xom ashyoni qayta ishlash bilan boshlanadi. Uchin kul yoki qum frezalash uchun konveyer lentalari orqali shar tegirmoniga tashiladi. Tegirmondan so'ng, hosil bo'lgan atala keyingi foydalanish uchun atala saqlash tankiga quyiladi.

2. Dozalash va aralashtirish

Ohak va tsement quruq kukunli o'lchov tarozilariga o'tkaziladi, u erda ular aniq o'lchanadi. Saqlash idishidan olingan atala ham avtomatik shkalaga pompalanadi. Keyin bu o'lchangan materiallar mikserda aralashtiriladi va qoliplarga quyiladi.

2. Qoliplash, chayish va oldindan qattiqlashtirish

The mixed slurry is poured into molds, which are then placed in a curing room maintained at 50 – 70 °C. After 2 – 3 hours of pre-curing, the blocks start to solidify.

3. Qolipdan tushirish va kesish

A reversal crane is used to carry the mold and block to a cutting cart for demoulding. The cutting cart then transports the block to a series of cutting machines, including level cutting, vertical cutting, and two-side cutting machines. The top waste material is also removed at this stage.

4. Avtoklavlash

Kesilgan yarim mahsulotlar avtoklav oldida guruhlanadi. Keyin yuk ko'taruvchi mashina yoki dragger bloklar bilan yuklangan bug' aravalarini bug' bilan ishlov berish uchun avtoklavga o'tkazadi, bu odatda 10-12 soat davom etadi. Bu jarayon AAC bloklarining mustahkamligi va chidamliligini sezilarli darajada oshiradi.

5. Qadoqlash va yuklash

Bloklar avtoklavdan chiqqandan so'ng, ularni qatlam-qatlam ajratish uchun ajratuvchi mashinadan foydalaniladi. Keyin tayyor mahsulotlar yuk ko'taruvchi ilgich bilan mahkamlanadi va yog'och tagliklarga qadoqlash liniyasiga joylashtiriladi. Nihoyat, forkliftlar qadoqlangan mahsulotlarni texnik shartlarga muvofiq yig'ish uchun saqlash maydonchasiga olib boradi.

Main Equipment Used in AAC Block Mini Plant

Sharli tegirmon: Kerakli noziklikka uchuvchi kul yoki qumni maydalash uchun zarur

Tuzli mikser: Turli xil xom ashyolarni bir hil aralashtirishni ta'minlaydi.

AAC qoliplari: bloklar shaklini olish uchun atala quyiladi.

Kesish mashinalari: These include level cutting, vertical cutting, and two-side cutting machines, which accurately shape the blocks.

Avtoklav: The heart of the process, where high-temperature steam treatment occurs.

Parom aravasi: Facilitates the movement of materials and semi-products within the plant.

Hot-Sale AAC Block Mini Plant

Advantages of AAC Block Mini Plant

Kamroq investitsiyalar: It needs fewer machines, less factory space, and uses less power and labor than large-scale plants. This cuts both initial costs and ongoing operations expenses.

Oson boshqaruv: Our automatic AAC Block Mini Plant is simple to operate, manage, and maintain. Its automatic batching system boosts feeding efficiency and accuracy-key for consistent AAC block quality.

Yangilangan texnologiya: Despite its small size, it follows the same high standards as large plants. This ensures top-quality AAC blocks with excellent insulation, fire resistance, and lightweight properties.

Eco-Friendly: It uses sustainable raw materials, and the final product is green too. With lower production capacity than medium or large plants, its carbon footprint is smaller.

Bizdan olishingiz mumkin bo'lgan xizmatlar

Moslashtirilgan AAC blokli zavod jarayoni va sxemasi dizayni:

Tajribali muhandislarimiz xarajatlarni minimallashtirish bilan birga samaradorlik va mahsuldorlikni maksimal darajada oshiradigan ishlab chiqarish jarayoni va zavod sxemasini loyihalashtiradi.

AAC blokli mashinalarni ishlab chiqarish va etkazib berish:

We provide high-quality AAC block machines.

Muhandislik qurilishi, uskunalarni o'rnatish, kadrlar tayyorlash:

Biz muhandislik qurilishi, asbob-uskunalarni o'rnatish va xodimlarni har tomonlama o'qitishni o'z ichiga olgan kalit taslim echimlarni taklif qilamiz. Bizning jamoamiz sizning zavodingiz qisqa vaqt ichida muammosiz ishlashini ta'minlaydi

Trial production of the whole AAC plant:

Zavodni sizga topshirishdan oldin, biz hamma narsa normal ishlashini ta'minlash uchun ishlab chiqarish liniyasi uskunalarini sinovdan o'tkazamiz.

Tips for the Layout of Small/AAC Block Mini Plant

- Qayta ishlashni kamaytirish uchun xomashyo hovlisi yo'lga yaqin joylashgan.

- Qolib aravalarining bir tomonlama harakatlanishini ta'minlash uchun I shaklidagi tartib qabul qilingan.

- Parallel avtoklavlar quvurlarni qisqartirish uchun bitta qozonni taqsimlaydi.

- Zaxiralarni yig'ish va yuklash/tushirish joylari bir tomonda joylashgan bo'lib, forkliftning burilish radiusi ≤5 metr.

- 10 m x 20 m maydon kengaytirishning ikkinchi bosqichi uchun ajratilgan - ishlab chiqarish quvvatini ikki baravar oshirish uchun ikkita avtoklav qo'shiladi.

Nima uchun bizni tanlaysiz?

Moslashtirish: We offer customized AAC Block Mini Plant process and layout design. Our team of experts works closely with our clients to ensure the plant is tailored to their specific production needs, site conditions, and budget constraints.

Yuqori sifatli Mashina: We are a leading manufacturer and supplier of AAC Block Mini Plant. All our equipment is manufactured to the highest standards, ensuring low failure rates and low maintenance costs. This results in minimal operating costs and high returns for our clients.

Global sertifikatlar: Idoralar, ASME, SONCAP (Eksport sertifikati).

Also read: AAC blok zavodi narxi