AAC blocks manufacturing machinery is a set of equipment designed to produce autoclaved aerated concrete (AAC) blocks. These machines play a crucial role in transforming raw materials into high-quality, lightweight building materials.

We supply various capacity AAC blocks manufacturing machinery from 30000m³/year to 6000000m³/year. With semi-automatic types and fully automatic types.

3 Types of AAC Blocks Manufacturing Machinery

According to production capacity, AAC Blocks Manufacturing Machinery can be divided into small, medium and large scale.

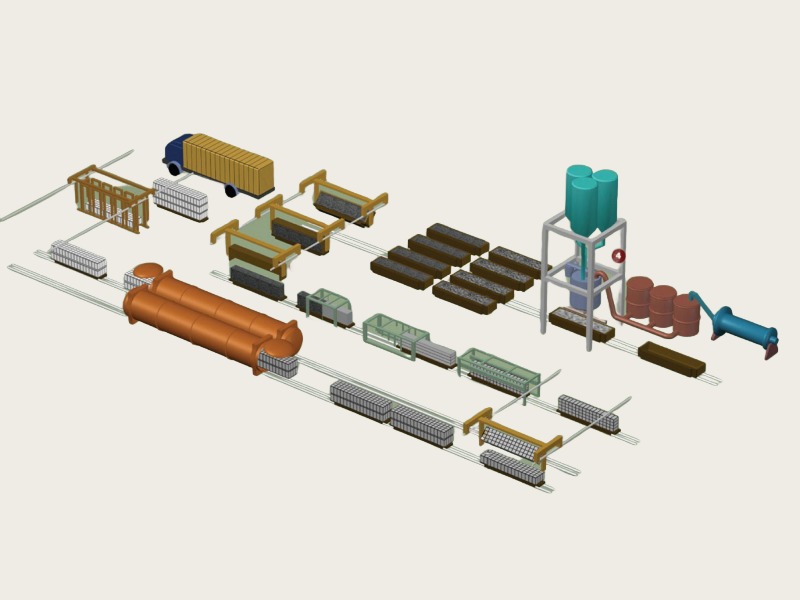

Mini/small AAC Blocks Manufacturing Machinery

Capacity: 30000-100000 m3/year

Avtoklav: 1-3 sets

Zavod: about 4000-10000m2

Types: semi-automatic/ fully automatic

Features: low initial investment, high flexibility.

Suitable for: Start-ups or enterprises with limited investment and small market demand.

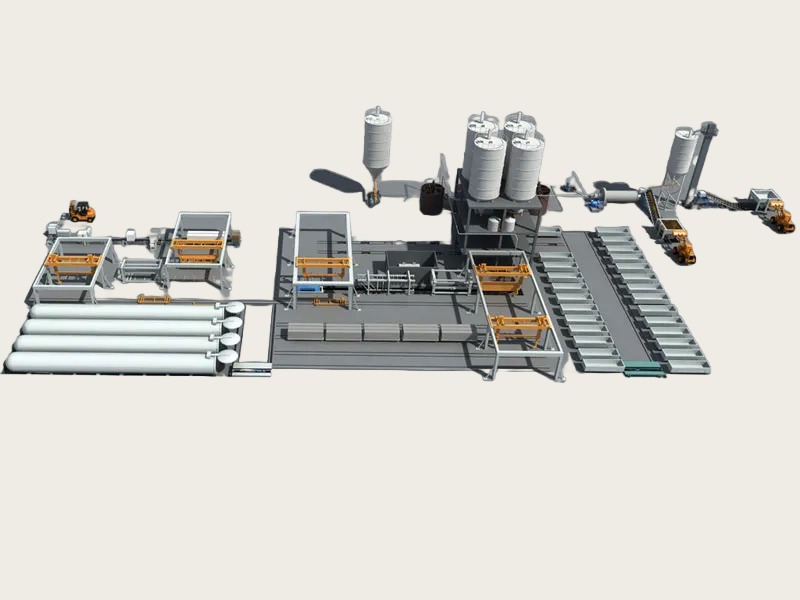

O'rta miqyosda AAC Blocks Manufacturing Machinery

Capacity: 100000-200000 m3/year

Avtoklav: 4-8 sets

Zavod: about 10000-20000m2

Type: fully automatic

Features: stable production capacity, controllable costs, flexibility, large-scale production, etc.

Suitable for: Enterprises with a certain market share and stable demand.

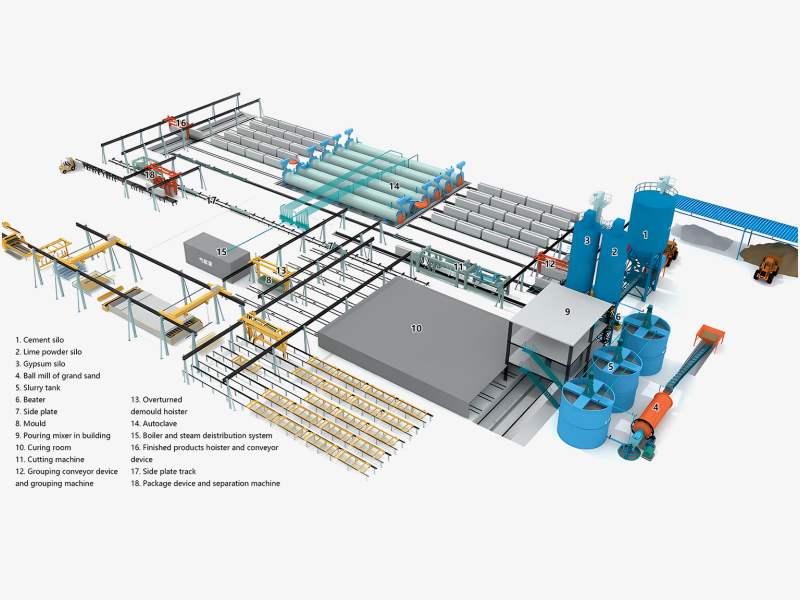

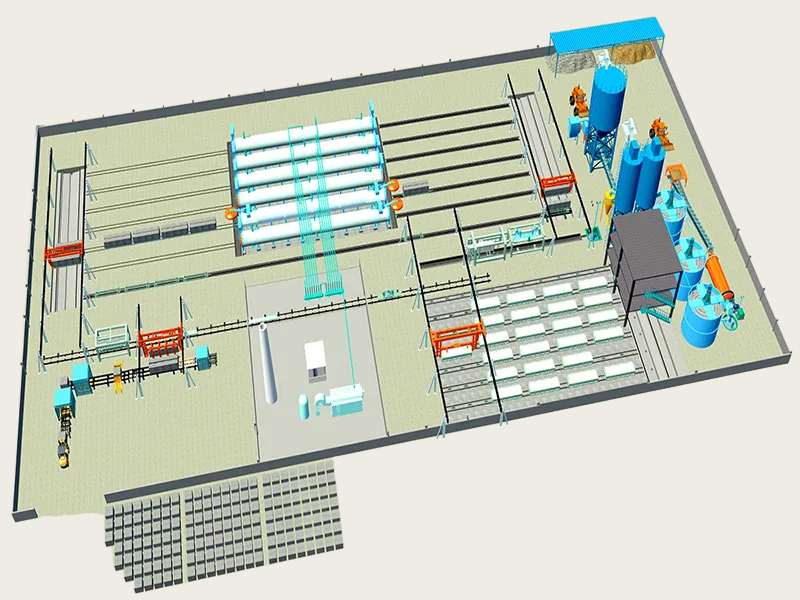

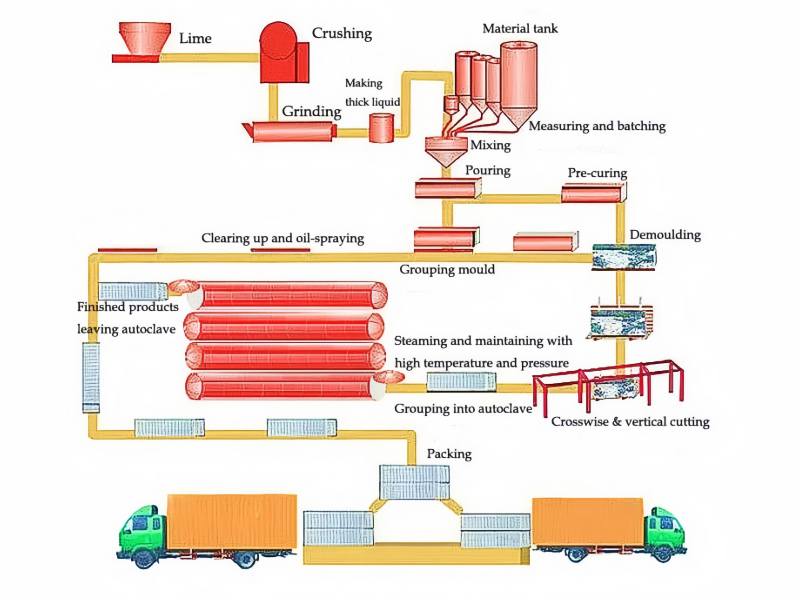

AAC Block Manufacturing Process

Raw material process → Batching and Mixing → Pouring → Static pre-curing → Cutting → Autoclaving Curing → Finished product Processing

1. Raw Material Processing: Sand is crushed and ground to the desired fineness. Cement, lime, and gypsum are stored in silos, and aluminum powder is mixed with water to form an aluminum slurry.

2. Batching and Mixing: The various raw materials are weighed according to precise proportions and then thoroughly mixed in a mixer to form a uniform slurry.

3. Pouring: The mixed slurry is poured into steel molds. The size and shape of the molds can be designed to meet the desired block specifications.

4. Static Pre-curing: The molds containing the slurry are transported to a pre-curing area where the slurry gradually hardens under suitable temperature and humidity conditions to achieve initial strength. This process typically takes several hours.

5. Cutting: After the slurry is pre-cured, it is cut into the desired size and shape using high-precision cutting equipment like steel wire or blades.

6. Autoclave Curing: Blocks are placed in an autoclave and cured for several hours at temperatures of 175-200°C and pressures of 10-15 bar, significantly enhancing the blocks’ strength and durability.

7. Finished Product Processing: After autoclave curing, the blocks are removed from the autoclave and transported to a storage area. After inspection and packaging, they are ready for shipment.

Machinery in AAC Block Manufacturing

1. Raw Material Handling Equipment

Sharli tegirmon: Used for finely crushing siliceous and calcareous materials such as sand, fly ash, and lime.

Jag' maydalagich: Crushes bulky raw materials (such as limestone) in preparation for subsequent grinding.

2. Mixing and Batching System

Mikser: Commonly used is a vertical shaft mixer, which uniformly mixes siliceous and calcareous materials, gas-generating agents (aluminum powder), and conditioning agents (gypsum) to ensure consistent block quality.

Batching System: Accurately measures and controls the raw material input ratio to ensure that block properties such as strength, density, and porosity meet specified standards.

3. Molding and Casting Equipment

Molds: Made of steel and designed to fit the block size, they hold the mixed slurry and shape it.

Pouring Equipment: Ensures smooth transfer of slurry to the mold, preventing air bubbles and uneven distribution.

4. Curing and Hardening Equipment

Pre-curing Chamber: Allows the slurry to initially solidify and strengthen in a controlled temperature and humidity environment, preparing it for subsequent processing.

Avtoklav: A large pressure vessel that uses high-temperature, high-pressure steam curing to induce chemical reactions in the raw materials, forming a strong and stable structure and enhancing the strength and durability of the blocks.

5. Cutting and Finishing Equipment

Cutting Machine: Cuts the pre-cured blocks horizontally and vertically (e.g., using a wire saw) to ensure dimensional accuracy.

Finishing Equipment: Optimizes the surface smoothness of the blocks through processes such as grinding to meet both aesthetic and functional requirements.

Factors Effecting Choosing the AAC Blocks Machinery

Choosing the right AAC Blocks Manufacturing Machinery is crucial for a successful production operation. Consider the following seven key factors:

1. Production Capacity

Determine your target market’s daily/hourly production output and select equipment that matches this output.

2. Level of Automation

- Fully automated AAC Blocks Manufacturing Machinery reduces manual intervention, increases production, and reduces labor costs, making it suitable for large-scale production.

- Semi-automated AAC Blocks Manufacturing Machinery requires more manual intervention but is more cost-effective, making it suitable for smaller-scale production.

3. Quality Control

Equipment must be reliable, including automated weighing and batching systems, precision mixing systems, and precise temperature and pressure control during the curing process. These features ensure consistent quality for each block.

4. Energy Efficiency

Energy efficiency directly impacts operating costs and the environment. Selecting equipment that optimizes energy consumption ensures economical and environmentally friendly production.

5. Maintenance and Support

Regular maintenance is crucial for the long-term, stable operation of your equipment. Choosing equipment from a reputable manufacturer ensures reliable technical support and timely availability of spare parts. Ease of maintenance is also important.

6. Equipment Durability

Highly durable equipment reduces maintenance downtime. Consider: high-quality materials and robust construction, and the manufacturer’s warranty.

7. Ease of Use

Easy-to-use equipment reduces operator learning curve and improves efficiency.

Cost of AAC Blocks Manufacturing Machinery

| Capacity Range | Total Investment Range | Estimated Payback Period |

|---|---|---|

| 30,000–100,000 m³ (Small) | $600,000–$1,300,000 | 2.0–2.5 years |

| 100,000–200,000 m³ (Medium) | $1,000,000–$2,800,000 | 2.0–2.8 years |

| 300,000–500,000 m³ (Large) | $2,000,000–$5,000,000 | 2.5–3.5 years |

The payback period is estimated based on a net profit margin of 25–30%. The actual period is subject to fluctuations in market prices, capacity utilization rate, and cost control efficiency.

AAC Blocks Manufacturing Technology

Advanced autoclaving technology

Cutting-edge cutting technology

Automated material handling

High-efficiency mixing and dosing

Energy-efficient design

Environmentally sustainable technology

Real-time monitoring and control

Quality control and testing

Modular and scalable design

Low labor requirements

Safety features

Digital twins and predictive

Application of AAC Block

Civil Buildings: Used in internal and external walls, floor slabs, roof slabs, etc. of residential buildings to reduce building weight and improve seismic performance.

Commercial Buildings: Suitable for non-load-bearing walls of shopping malls, hotels, office buildings, etc., with good thermal insulation and sound insulation effects to enhance building comfort.

Industrial Buildings: Served as wall and partition materials for factories and warehouses, meeting the special requirements of industrial production for building materials.

Special Buildings: Widely applied in hospitals, schools, gymnasiums and other places due to their excellent fire resistance and environmental protection properties.

Features and AAC bloklarining afzalliklari

Yengil va yuqori quvvatli

Its low density, only 1/3-1/4 that of ordinary concrete, effectively reduces the weight of buildings while maintaining high strength to meet structural requirements.

Issiqlik izolyatsiyasi

Its porous internal structure provides excellent thermal insulation, reducing building energy consumption by over 30% and improving energy efficiency.

Zo'r yong'inga chidamlilik

As a non-combustible material, it boasts a fire resistance limit of 3-4 hours, effectively slowing the spread of fire and protecting life and property.

Zo'r ovoz o'tkazmaydigan

Its porous structure effectively blocks sound transmission, enhancing the building’s sound insulation and creating a quiet and comfortable living and working environment.

Oson qurilish

AAC blocks are precisely sized and can be sawed, planed, and nailed, making the construction process simple and convenient, improving efficiency and shortening the construction period.

Ekologik toza

The production process consumes industrial waste, reducing environmental pollution. No harmful gases are released during use, meeting green building requirements.

World’s 5 Leading AAC Machinery Manufacturers

1. HESS Group (Germany)

With over 70 years of experience, we have built over 100 complete AAC plants worldwide.

The superSMART series is renowned for its high-speed horizontal cutting and fully automated steam curing, with a single machine boasting a daily production capacity exceeding 2,000 m³.

With technical centers in Europe, North America, and Asia, HESS Group provides comprehensive EPC services, from process design to operations and maintenance training.

2. Masa Group (Germany)

With over 110 years of experience in concrete products, Masa offers complete AAC slab and block production lines with annual capacity ranging from 300,000 to 600,000 m³.

Its intelligent MES system supports remote diagnostics and predictive maintenance.

Masa Group has spare parts centers in Germany, the United States, and China, with a global response time of less than 24 hours.

3. Anhui KEDA Industrial Co. (China)

China’s largest complete AAC production line supplier, with over 50 production lines in operation overseas, covering India, the Middle East, Southeast Asia, and Eastern Europe.

Our independently developed zero-waste cutting system and energy-saving steam curing kiln help customers reduce costs by an average of 8-12%.

4. Wehrhahn GmbH (Germany)

With over 100 years of experience in AAC technology, renowned for its highly customized capabilities.

The AKG Çorlu project in Turkey boasts a daily production capacity of 2,074 m³, setting a new global record for the largest single unit.

The superSMART 2000 series supports seamless expansion to reinforced AAC panels, providing investors with room for future upgrades.

5. Aircrete Europe BV (Netherlands)

As the global pioneer in flat-bread cutting and horizontal steam curing, we have built over 100 AAC plants in 20 countries.

The modular Flat-Cake system reduces board scrap rates to less than 0.5%, making it highly sought after in the high-end board market.

The above five manufacturers all have turnkey EPC capabilities and can provide differentiated solutions based on customers’ production capacity, budget and environmental requirements. They are the preferred partners for building or upgrading AAC plants around the world.

Services We Offer

- Loyihani rejalashtirish va loyihalash

Mijozlarning ehtiyojlari va haqiqiy sharoitlarga asoslangan AAC bloklari zavodlari uchun umumiy rejalashtirish va batafsil dizayn sxemalarini taqdim eting, shu jumladan jarayonni loyihalash, uskunalarni joylashtirish va qurilish muhandislik dizayni. - Uskunalarni etkazib berish va o'rnatish

Supply full sets of AAC production line equipment, undertake installation and commissioning to ensure normal operation, meeting your designed capacity and product quality standards. - Texnik ta'lim

Operatorlar, texniklar va menejerlar uchun ishlab chiqarish jarayonlari, uskunalardan foydalanish, texnik xizmat ko'rsatish va sifatni boshqarish bo'yicha professional treninglarni taklif qiling. - Sotishdan keyingi xizmat

Uzluksiz barqaror ishlab chiqarishni ta'minlash uchun kundalik parvarishlash bo'yicha ko'rsatmalar, nosozliklarni bartaraf etish va ehtiyot qismlar bilan ta'minlash bo'yicha ishonchli sotuvdan keyingi tizimni yarating. - Texnik qo'llab-quvvatlash va yangilash

Doimiy texnik yordam ko'rsating va samaradorlik va sifatni yaxshilash uchun mijozlar ehtiyojlari va sanoat tendentsiyalariga asoslangan uskunalarni yangilash/texnik o'zgartirish echimlarini taklif qiling. - EPC Bosh pudratchi

Muammosiz tajriba uchun loyihalash, asbob-uskunalarni xarid qilish, fuqarolik qurilishi, o'rnatish va o'qitishdan tortib, sinov ishlab chiqarishgacha bir martalik EPC xizmatlari.