180,000 m³/Year AAC Block Line in UK

In March 2024, our company successfully exported a fully automatic AAC block production line à Manchester, United Kingdom. As a professional AAC block manufacturing plant manufacturer with over 20 years of industry experience and equipment exported to 80+ pays, we were selected by a UK construction group seeking a long-term, energy-efficient AAC block production solution.

- Annual Capacity: 180,000 m³/year

- Plant Category: Medium AAC Plant (100,000 – 200,000 m³/year)

- Setup Cost Range: USD 1,200,000 – 2,300,000

- Niveau d'automatisation : Entièrement automatique

- Control System: Siemens PLC + UK-standard electrical components

- Target Market: Residential & commercial construction sectors across the UK

End Products:

- Load-bearing AAC blocks

- Non-load-bearing blocks

- Thermal insulation blocks

The client is a well-established construction materials supplier in Manchester, with business covering building blocks, dry-mix mortar, and roofing materials. Facing rising logistics costs and an increasing demand for AAC blocks locally, the client planned to:

Client objectives:

- Establish their first AAC production facility

- Reduce reliance on imported AAC products

- Build a stable supply chain for regional developers

- Produce high-precision AAC blocks for energy-efficient housing projects

- Use automation to reduce labor cost (which is high in the UK)

After evaluating suppliers from Europe and Asia, the client selected us for our rich experience, strong engineering capability, and proven track record in exporting large AAC lines.

Our Customized Solution for the AAC Block Line in UK

To meet the UK’s strict construction and environmental regulations, we provided a bespoke AAC solution tailored to the client’s land size, product requirements, and expected ROI.

Customizations included:

✔ 1. UK-standard electrical & safety compliance

- CE-compliant electrical cabinet

- Safety interlocks

- UK voltage specification (400V, 50Hz)

✔ 2. Fully Automatic Cutting Technology

High-precision cutting tolerance of ±1.0 mm, ideal for high-end housing projects and large contractors.

✔ 3. Energy-Saving Steam System

We adopted an optimized autoclave steam recycling process that reduced energy consumption by 12–15%, lowering operating cost in the UK’s high-energy-price environment.

✔ 4. Dust-Control & Environmental System

To comply with UK environmental regulations, we added:

- Enclosed conveyor system

- Dust collection filters

- Noise control systems

✔ 5. Space-Optimized Plant Layout

Designed based on the client’s 12,000 m² site to maximize material flow efficiency.

✔ 6. UK English User Interface (HMI)

Easy to operate, ideal for local workers with no AAC experience.

Advantages of AAC Block Line in UK

1. High Automation → Reduced Labor Cost

Only 15–18 workers required for full operation—important for UK labor market conditions.

2. High Cutting Precision

Ensures stable quality for load-bearing and insulation blocks used in the UK market.

3. Lower Energy Consumption

Optimized curing system significantly lowers production cost.

4. Excellent Durability & Stability

Equipment designed for 20+ years of continuous operation.

5. Strong Environmental Compliance

Dust control + noise reduction → fully meets UK industrial standards.

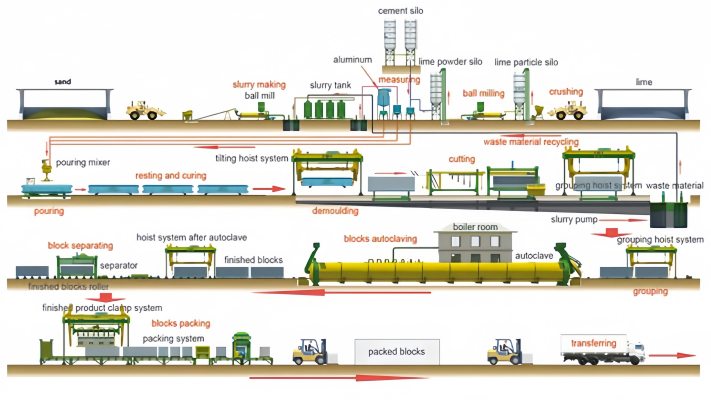

Main Equipment Used in This AAC Plant

- Raw material batching system

- Automatic slurry mixing & pouring station

- Aluminum dosing equipment

- Molds & pre-curing chamber

- Tilting and de-molding crane

- High-precision vertical & horizontal cutting machines

- Waste recycling and slurry return system

- Autoclaves (Φ2.68 × 32 m)

- Boiler and steam pipeline

- Finished block packaging robot

- Siemens PLC control system

Complete Production Process

- Sand grinding

- Slurry mixing

- Aluminum dosing

- Pouring into molds

- Prépolymérisation

- Tilting & de-molding

- Vertical + horizontal precision cutting

- Grouping

- Durcissement en autoclave

- Cooling

- Packing & palletizing

The entire line is optimized for continuous and stable production.

Service Workflow: From First Inquiry to Final Commissioning

1. Initial Inquiry: Client contacted us requesting a 150,000–200,000 m³/year AAC line.

2. Technical Proposal

We provided:

- 3D plant layout

- Cost breakdown

- Energy consumption analysis

- ROI calculation

3. Contract Signed & Manufacturing Started

4. Production, Testing & Quality Inspection

5. Shipment to the UK: Equipment delivered to Port of Liverpool.

6. On-Site Installation

Our engineers handled:

- Equipment installation

- Electrical wiring

- Operator training

7. Successful Trial Production: The Usine AAC reached stable production output within the first month.

Performance Results After Operation

After the first 60 days of production, the factory achieved:

✔ Daily Production Output

550–600 m³/day stable output.

✔ Energy Efficiency

Steam consumption reduced by 12–15%.

✔ Perfect Dimensional Accuracy

Consistent cutting precision at ±1.0 mm.

✔ Lower Operating Cost

Automation reduced labor requirements significantly compared to expectation.

What Our Client Says?

“The AAC block line you supplied has delivered exceptional performance.

Its automation level, production accuracy, and overall stability are far beyond what we expected.”

Pourquoi nous choisir ??

✔ 20+ years of AAC manufacturing expertise

✔ Exported to more than 80 countries

✔ Full turnkey engineering: design → manufacturing → installation → training

✔ European-standard components (Siemens, Schneider)

✔ High automation helps reduce UK labor cost

✔ Proven energy-saving technology to lower production cost

We continue to support UK customers with stable, efficient AAC block production solutions.

Ready to Build an Usine de fabrication de blocs AAC?

Contact us for:

- Customized AAC plant layout

- Cost estimation & ROI analysis

- Turnkey engineering services

- Energy-saving production design

We’re here to help you launch a profitable and sustainable AAC project in your country.