What is AAC Block?

Raw Materials: AAC Block (Autoclaved Aerated Concrete Block) is made from key materials including sand, cement, gypsum, lime, and aluminum paste.

Production Processes: It undergoes professional procedures: batching, mixing, pouring, aerating, static pre-curing, cutting, and high-temperature high-pressure autoclaving.

Core Feature: The aeration process creates numerous uniform tiny pores inside the block.

Key Advantages: Offers light weight, high strength, thermal insulation, soundproofing, and excellent fire resistance.

Applications: Widely used in wall masonry and structural work for civil, commercial, and industrial buildings.

AAC Block Plant for Sale

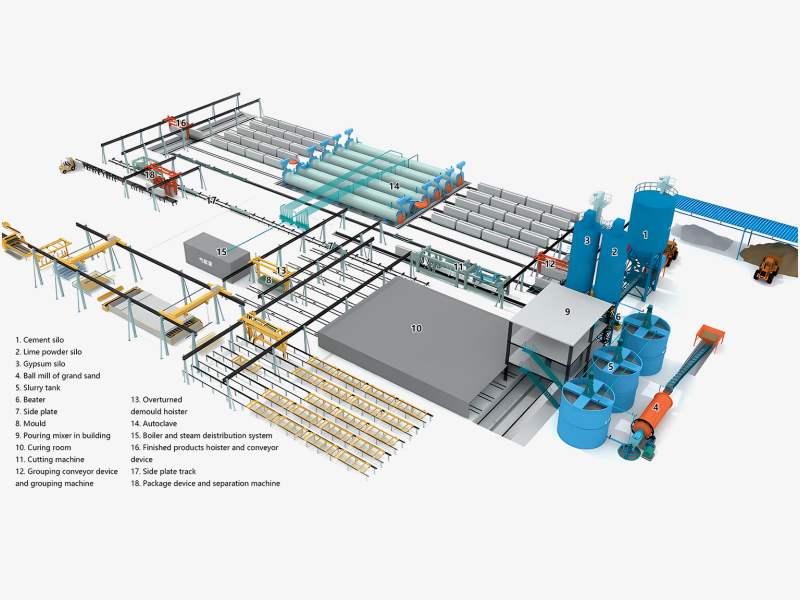

AAC bloklari zavodi, or Autoclaved Aerated Concrete Block Production Plant, is an industrial facility for large-scale AAC block manufacturing.

It includes a full set of equipment from raw material processing to finished product packaging: core equipment covers ball mills, jaw crushers, batching and mixing systems, pouring equipment, cutting units, autoclaves, conveyors, bucket elevators, overturning machines, and pallet wrappers.

Through continuous production processes, raw materials are converted into qualified AAC blocks, forming an efficient, stable and environmentally friendly professional production system.

End product: AAC Block( autoclaved aerated concrete block)

Capacity: 30,000-600,000 cubic meters/year

Standard: Chinese, ASME, EU, and others

Automation Grade: Semi-automatic/ fully automatic

Brick Material: Fly Ash/Sand

Brick Dimension: 4m, 4.2m, 4.8m, and 6m or customized

Certificate: ISO 9001

Types of AAC Block Plant for Sale

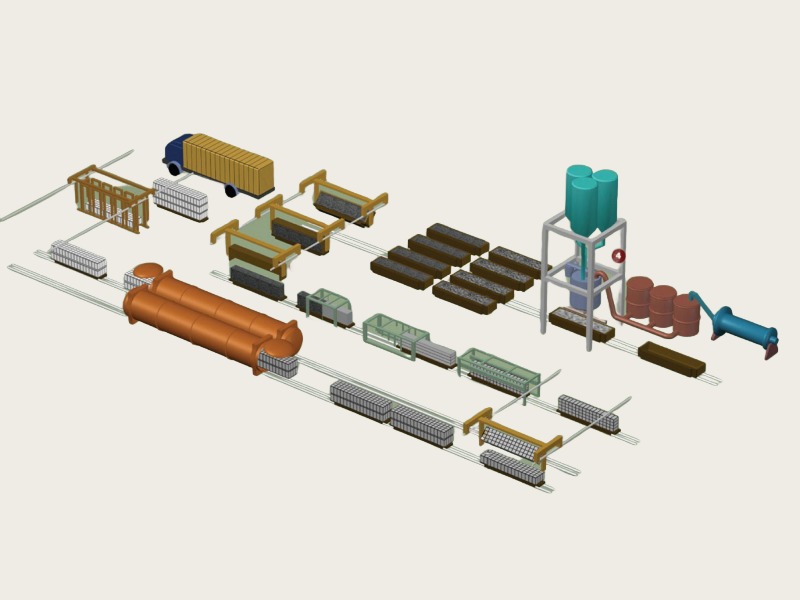

Mini/small AAC Block Plant

Capacity: 30000-100000 m3/year

Avtoklav: 1-3 sets

Zavod: about 4000-10000m2

Types: semi-automatic/ fully automatic

Features: low initial investment, high flexibility.

Suitable for: Start-ups or enterprises with limited investment and small market demand.

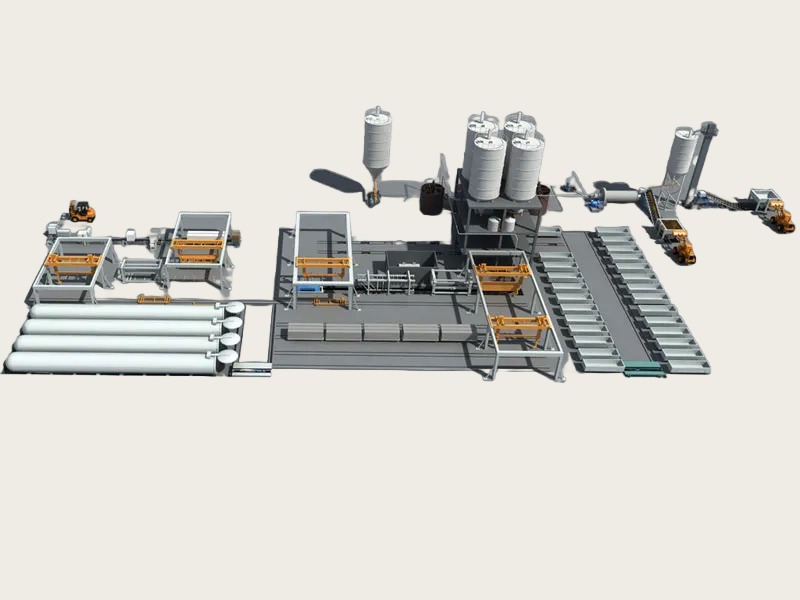

Medium-Scale AAC Block Plant

Capacity: 100000-200000 m3/year

Avtoklav: 4-8 sets

Zavod: about 10000-20000m2

Type: fully automatic

Features: stable production capacity, controllable costs, and flexibility and large-scale production.

Suitable for: Enterprises with certain market share and stable demand.

AAC Block Plant for Sale

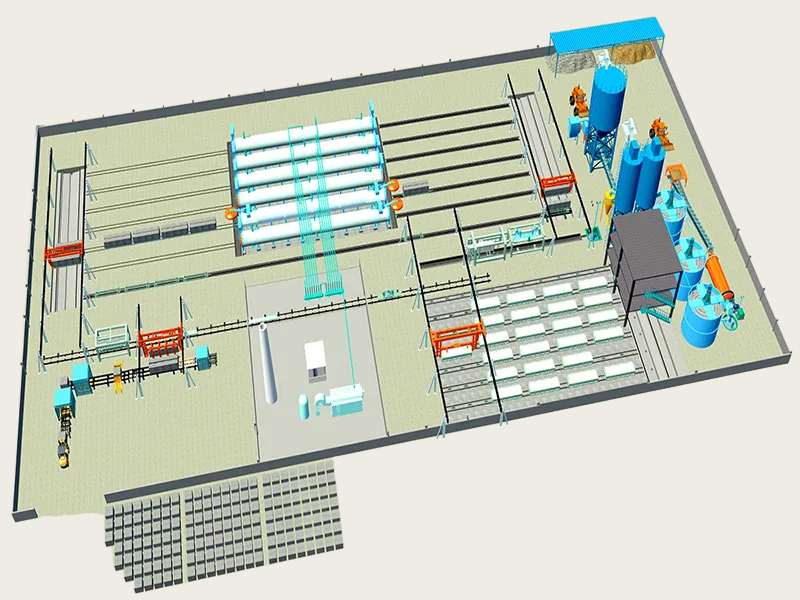

200,000 m³ AAC block plant

Advantages: Large-scale facility with upgraded conveying/mixing systems, designed for high-volume continuous production.

Suitable for: Leading regional companies and multinational building materials groups.

400,000 m³ AAC block plant

Capacity: 400,000 cubic meters per year, suitable for large-scale supply.

Advantages: Super-large complex with top-tier core equipment and optimized processes to efficiently meet extensive market demands.

Super-large complex with top-tier core equipment and optimized processes to efficiently meet extensive market demands.

Machines used in AAC Block manufacturing

1. Jaw Crusher

Perform preliminary crushing on bulk raw materials (e.g., lime, gypsum), breaking large-particle raw materials into sizes meeting subsequent processing requirements to lay the foundation for grinding and homogenization.

2. Ball Mill

Finely grind the crushed siliceous raw materials (sand, fly ash) and calcareous raw materials (lime) to make the raw materials meet the specified fineness standards and ensure sufficient subsequent batching reactions.

3. Vibrating Screen

Screen the ground raw materials to remove unqualified coarse particle impurities and ensure that the particle size of the raw materials entering the batching link meets the process requirements.

4. Screw Conveyor / Bucket Elevator

Transport various processed raw materials (sand, cement, lime, etc.) from the storage bin to the batching system to realize automatic transfer of raw materials.

5. Forced Mixer

Fully mix the measured raw materials with water and aluminum powder foaming agent to form a uniform slurry, providing a stable material foundation for subsequent pouring and foaming.

6. Pouring Machine

Uniformly pour the mixed slurry into the mold to ensure that the slurry is distributed flatly in the mold and create conditions for the foaming and forming of the blank.

7. Pre-curing room

Provide a constant temperature and humidity static environment for the poured mold, allowing the slurry to complete the foaming reaction and initial setting process and form a blank with a certain strength.

8. Mold

Serve as a carrier for slurry foaming and blank forming, determining the initial shape and size of the blank.

9. Turnover Demolding Machine

Separate the static blank from the mold, and place the blank stably on the cutting table through turning to prepare for subsequent cutting.

10. Cutting Unit (Horizontal Cutting + Vertical Cutting)

Cut the demolded blank into blocks or plates that meet the specifications, with a cutting accuracy of up to ± 1mm.

The horizontal cutting machine is responsible for cutting the blank in the horizontal direction, and the vertical cutting machine completes the cutting in the vertical direction.

11. Autoclave

It is the core equipment for AAC block production. It cures the cut blank with high-temperature and high – pressure steam (usually at a temperature of 180- 200℃ and a pressure of 0.8- 1.2MPa) to promote the full reaction of raw materials and form a high – strength structure.

12. Pre-autoclave Conveyor

Neatly group the cut blanks and transport them to the entrance of the autoclave to ensure that the blanks enter the autoclave in an orderly manner.

13. Post-autoclave Conveyor

Transport the autoclaved and cured finished products from the autoclave to the subsequent processing area to complete the out – of – autoclave transfer.

14. Pallet Wrapper

Wrap and package the qualified finished blocks after inspection to fix the stacking form of the blocks for easy storage and transportation.

15. PLC Control System

As the control centre of the entire production line, it realizes functions such as monitoring of equipment operating parameters, automatic control of the production process and fault alarm.