The Small Scale AAC Block Plant is an autoclaved aerated concrete block production line with an annual output of less than 100,000 cubic meters, used to produce lightweight, porous AAC building blocks.

Main features: low investment, a small footprint, ease of management, and allows for future upgrades. Its production standards are the same as with those of large-scale production lines.

- Price range of Semi-automated small scale AAC block plant (30,000-50,000m3/year): Approximately $100,000-$200,000, suitable for startups.

- Price range of Fully automated small scale AAC block plant (50,000-100,000m3/year): Approximately $200,000-$400,000, suitable for small and medium-sized enterprises with stable orders.

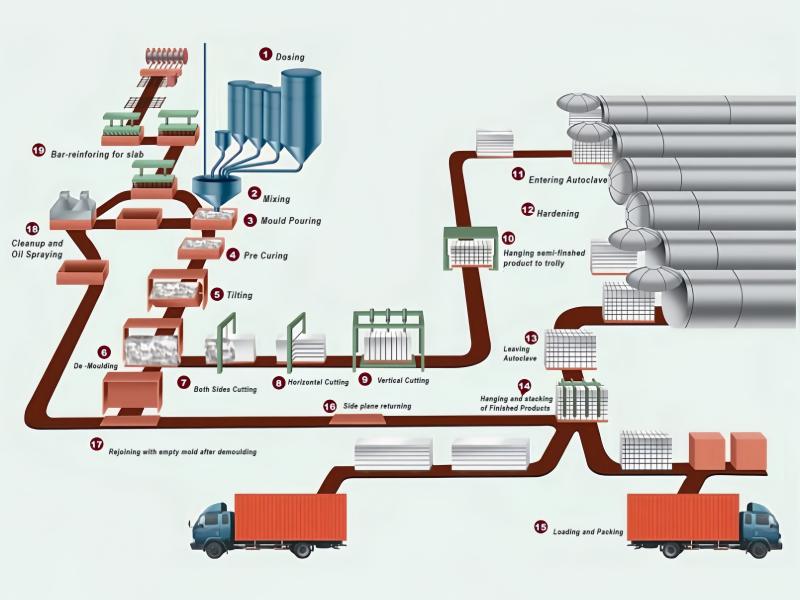

The production process consists of six steps: raw material processing (crushing and screening), batching and mixing, pouring and aeration, pre-curing and cutting, autoclaving, and finished product processing.

Key equipment includes a ball mill, electronic batching system, pouring mixer, tilting cutter, autoclave and boiler, dust removal, and other auxiliary equipment.

Imkoniyati: <100 000 m³/yil

Avtoklavlar: 3-4

Zavod maydoni: 4000 -5000 m2

End product: AAC Block/Panels

Suitable for: small building material suppliers

Standart: Xitoy, ASME, EI va boshqalar

Automation Grade: Semi-automatic, Fully Automatic

G'isht materiali: Fly Ash/Sand

G'isht o'lchami: moslashtirilgan

Sertifikat: ISO 9001

Advantages of Small Scale AAC Block Plant

Lower Investment

A key advantage of Small Scale AAC Block Plant is setup cost savings. They need fewer equipment, smaller factory space, and less power/labor than larger facilities, cutting overall investment significantly.

Simplified Management

Automatic Small Scale AAC Block Plants are easy to operate, manage, and maintain. Their automatic batching system boosts feeding efficiency and accuracy-critical for proper ingredient ratios and mixing that impact block quality.

Advanced Technology

The small plant manufacturing meets large-scale plant standards. Using world-leading technology, so as to ensure reliable production quality.

Eco-Friendly Performance

Small AAC block plants use eco-friendly raw materials and produce green end products. With lower capacity than medium/large plants, they have a smaller carbon footprint, fitting green development needs.

Process of Small Scale AAC Block Plant

1. Xom ashyo jarayoni

Jarayon xom ashyoni qayta ishlash bilan boshlanadi. Uchin kul yoki qum frezalash uchun konveyer lentalari orqali shar tegirmoniga tashiladi. Tegirmondan so'ng, hosil bo'lgan atala keyingi foydalanish uchun atala saqlash tankiga quyiladi.

2. Dozalash va aralashtirish

Ohak va tsement quruq kukunli o'lchov tarozilariga o'tkaziladi, u erda ular aniq o'lchanadi. Saqlash idishidan olingan atala ham avtomatik shkalaga pompalanadi. Keyin bu o'lchangan materiallar mikserda aralashtiriladi va qoliplarga quyiladi.

2. Qoliplash, chayish va oldindan qattiqlashtirish

Aralashtirilgan atala qoliplarga quyiladi, so'ngra ular 50-70 ° C haroratda saqlanadigan quritish xonasiga joylashtiriladi. 2-3 soat oldindan quritishdan so'ng, bloklar qattiqlasha boshlaydi.

3. Qolipdan tushirish va kesish

Qaytaruvchi kran qolipni va blokni qolipdan tushirish uchun kesish aravasiga olib borish uchun ishlatiladi. Keyin chiqib ketish aravachasi blokni bir qator kesish mashinalariga, jumladan, tekis kesish, vertikal kesish va ikki tomonlama kesish mashinalariga olib boradi. Ushbu bosqichda yuqori chiqindilar ham chiqariladi.

4. Avtoklavlash

Kesilgan yarim mahsulotlar avtoklav oldida guruhlanadi. Keyin yuk ko'taruvchi mashina yoki dragger bloklar bilan yuklangan bug' aravalarini bug' bilan ishlov berish uchun avtoklavga o'tkazadi, bu odatda 10-12 soat davom etadi. Bu jarayon AAC bloklarining mustahkamligi va chidamliligini sezilarli darajada oshiradi.

5. Qadoqlash va yuklash

Bloklar avtoklavdan chiqqandan so'ng, ularni qatlam-qatlam ajratish uchun ajratuvchi mashinadan foydalaniladi. Keyin tayyor mahsulotlar yuk ko'taruvchi ilgich bilan mahkamlanadi va yog'och tagliklarga qadoqlash liniyasiga joylashtiriladi. Nihoyat, forkliftlar qadoqlangan mahsulotlarni texnik shartlarga muvofiq yig'ish uchun saqlash maydonchasiga olib boradi.

Main Equipment in Small Scale AAC Block Plant

Sharli tegirmon: Kerakli noziklikka uchuvchi kul yoki qumni maydalash uchun zarur

Tuzli mikser: Turli xil xom ashyolarni bir hil aralashtirishni ta'minlaydi.

AAC qoliplari: bloklar shaklini olish uchun atala quyiladi.

Kesish mashinalari: Bularga tekis kesish, vertikal kesish va bloklarni aniq shakllantiradigan ikki tomonlama kesish mashinalari kiradi.

Avtoklav: Yuqori haroratli bug' bilan ishlov berish jarayoni sodir bo'ladigan jarayonning yuragi.

Parom aravasi: Zavod ichida materiallar va yarim mahsulotlarning harakatlanishini osonlashtiradi.

Hot-Sale Small Scale AAC Block Plant

50,000 m³ Small Scale AAC Block Plant

Cost: $300,000-$600,000

Delivery time: 3-4 months

Advantages: Quick return on investment, low barrier to entry, the ability to rent land for factory construction, and manageable staff size.

Suitable for: Individual entrepreneurs and small and medium-sized enterprises.

Bizdan olishingiz mumkin bo'lgan xizmatlar

Moslashtirilgan AAC blokli zavod jarayoni va sxemasi dizayni:

Tajribali muhandislarimiz xarajatlarni minimallashtirish bilan birga samaradorlik va mahsuldorlikni maksimal darajada oshiradigan ishlab chiqarish jarayoni va zavod sxemasini loyihalashtiradi.

AAC blokli mashinalarni ishlab chiqarish va etkazib berish:

We provide high-quality AAC block machines.

Muhandislik qurilishi, uskunalarni o'rnatish, kadrlar tayyorlash:

Biz muhandislik qurilishi, asbob-uskunalarni o'rnatish va xodimlarni har tomonlama o'qitishni o'z ichiga olgan kalit taslim echimlarni taklif qilamiz. Bizning jamoamiz sizning zavodingiz qisqa vaqt ichida muammosiz ishlashini ta'minlaydi

Butun AAC zavodining sinov ishlab chiqarishi:

Zavodni sizga topshirishdan oldin, biz hamma narsa normal ishlashini ta'minlash uchun ishlab chiqarish liniyasi uskunalarini sinovdan o'tkazamiz.

Top 5 Manufacturers of Small Scale AAC Block Plant

1. Guangxi Hongfa Heavy Industry Machinery Co., Ltd.

- Main Products: AAC block/ALC wall panel making plants (with an annual output of 50,000 – 500,000 m³), concrete mixing plants, and block forming machines.

- Features: It offers customizable semi-automatic or fully automatic Small Scale AAC Block Plant, equipped with PLC control systems and compatible with 380V/220V power supplies. The products have obtained CE certification. The company provides overseas installation, commissioning, and training services, and has a short after-sales service cycle.

- Suitable Enterprise Types: Startups with limited budgets, small and medium-sized building material factories planning to expand their product portfolios, and export-oriented enterprises.

2. Henan Zhengyi Building Material Machinery Manufacturing Co., Ltd.

- Main Products: AAC block/panel manufacturing plants (annual output of 50,000 – 300,000 m³), cutting machines, and autoclaves.

- Features: The equipment adopts a modular design, and customers can optionally equip it with Siemens motors or Schneider PLCs. It is equipped with a waste heat recovery system that reduces energy consumption by 18%, and its dust emission is less than 10mg/m³. It also supports customization for alpine or seismic regions.

- Suitable Enterprise Types: Enterprises focusing on energy conservation and environmental protection, as well as manufacturers planning to enter overseas markets such as Central Asia and Russia.

3. Dongyue Machinery Group Co., Ltd.

- Main Products: AAC block/panel manufacturing plants (annual output of 50,000 – 300,000 m³).

- Features: The production lines absorb German technology and have a high level of automation. The company has nearly 500 project cases worldwide and provides one-stop services including planning, installation, commissioning, and training. Its products have obtained CE, ISO, and SGS certifications.

- Suitable Enterprise Types: Enterprises pursuing stable and efficient production and aiming to reduce operating costs, especially those suitable for large-scale replicated production.

4. Jiangsu Huilong International Co., Ltd.

- Main Products: AAC block manufacturing plants (annual output of 30,000 – 300,000 m³), cutting machines, molds, and autoclaves.

- Features: Multiple specifications of molds are available, with an hourly output ranging from 1,280 to 12,000 blocks. The company also provides factory design and automation solutions.

- Suitable Enterprise Types: Small and medium-sized enterprises with limited factory space and expecting to launch production quickly, as the equipment supports flexible capacity adjustment.

5. Henan Lanshan Machinery Manufacturing Co., Ltd.

- Main Products: Small Scale AAC block Plant.

- Features: The equipment has a small footprint and low investment, making it suitable for the initial operation stage. It also supports customized configurations.

- Suitable Enterprise Types: Individual operators or small processing plants that are entering the AAC field for the first time and face constraints in capital and site.

Tegishli AAC zavodi

Related: AAC Block Mini Plant, Mini AAC Plant Cost, Avtoklavlangan gazbeton AAC zavodi