A 20,000 m3/year AAC block plant is a compact production line designed to produce approximately 55–65 cubic meters of AAC blocks per day, depending on the number of working days per year.

This small-scale AAC production line offers everything required to manufacture high-quality AAC blocks while keeping capital cost, land requirements, and operational expenses at a practical level. Whether you are an entrepreneur, a building material distributor, or a local construction company looking to diversify, this plant capacity is the ideal entry point.

Capacity: 20,000 m³/year

Autoclaves: 3-4

End product: AAC Block/Panels

Suitable for: small building material suppliers

Standard: Chinese, ASME, EU, and others

Automation Grade: Semi-automatic, Fully Automatic

Brick Material: Fly Ash/Sand

Brick Dimension: customized

Certificate: ISO 9001

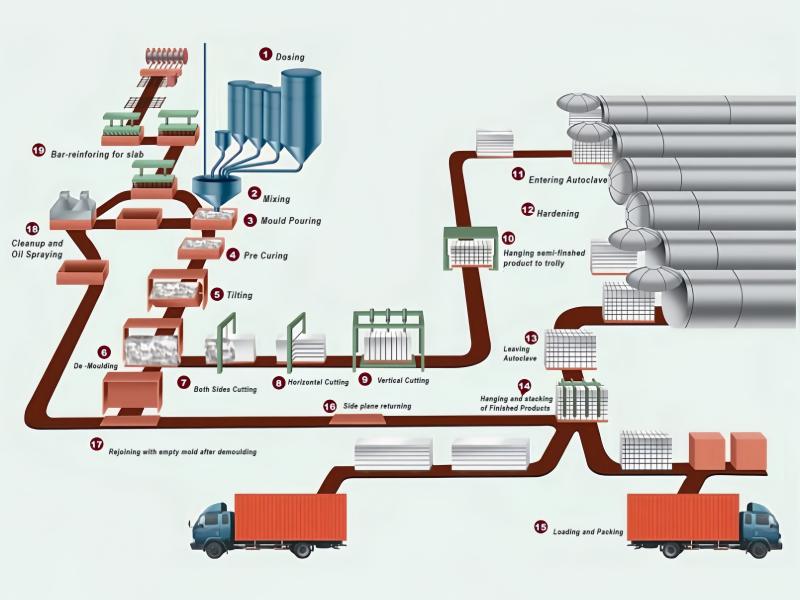

Process of 20,000 m3/year AAC Block Plant

Below is the complete workflow used in small AAC plants.

Step 1 — Raw Material Storage & Batching

Cement, lime, gypsum, fly ash/sand are stored in silos or ground storage and fed into weighing systems.

Step 2 — Slurry Mixing

Materials are blended into slurry using a high-efficiency mixer. Aluminum powder is added precisely to ensure correct density and strength.

Step 3 — Casting

Slurry is poured into moulds. Rising and foaming occur naturally during pre-curing.

Step 4 — Pre-Curing (2–3 hours)

The “green cake” becomes semi-solid and ready for demoulding.

Step 5 — Demoulding & Tilting

The mould is tilted 90 degrees, and the green body is separated from the mould.

Step 6 — Cutting

The green cake is cut horizontally and vertically into precise block sizes. Block tolerance is usually ±1.5mm to ±3mm, depending on the cutting system.

Step 7 — Autoclaving (8–12 hours)

Blocks are loaded into autoclaves and cured using saturated steam at 1.2–1.4 MPa.

This process ensures high compressive strength (3.0–4.5 MPa).

Step 8 — Block Packing

Finished blocks are separated, stacked, and packed for delivery.

Who Is This Plant Suitable For?

The 20,000 m³/year model is ideal for:

- First-time AAC investors

- Local construction suppliers

- Small and mid-sized builders

- Block traders turning into manufacturers

- Rural or county-level construction markets

- Regions switching from clay bricks to AAC blocks

It is one of the most popular capacities in Africa, Southeast Asia, South Asia, Middle East small cities, and Latin American developing regions.

Key Features & Advantages of a 20,000 m³/year AAC Block Plant

✔ Advantage 1 — Low Investment & Fast Startup

Since the plant size is small, the investment required for:

- equipment

- land

- installation

- foundation

- electricity supply

- worker training

It is significantly lower than larger plants. Many investors recover their investment within 9–15 months depending on their local market conditions.

It is one of the few AAC plant models that can begin production within 45–60 days after equipment reach the site.

✔ Advantage 2 — Lower Operating Cost

A 20,000 m³/year AAC plant typically requires:

- 5–10 workers

- smaller autoclaves (Φ2×20m or Φ2×22m)

- low energy consumption

- compact land area (6,000–8,000 m²)

- lower steam and electricity cost

This reduces monthly operational expense and gives higher profit margins.

✔ Advantage 3 — Easy Maintenance & Simple Operation

Because the entire production line is simpler than medium or large plants, the operator learning curve is short. Most customers reach stable production after 1–2 weeks of training.

Cutting machines, slurry systems, and mould operations are also optimized for small-scale use.

✔ Advantage 4 — Flexible Market Positioning

A 20,000 m³ plant can serve:

- small cities

- county-level building areas

- rural construction markets

- private developers

- road & bridge projects

- industrial parks

- small real estate clusters

This flexibility makes it suitable for markets where demand is growing but not large enough for high-capacity plants.

✔ Advantage 5 — Lower Risk, Higher ROI

Investors choosing 20,000 m³ plants often appreciate:

- low production risk

- fast cash flow

- stable daily output

- minimal equipment downtime

- easy spare parts access

This plant size gives excellent cost–performance ratio and is considered the safest starting point for new AAC manufacturers.

Main Equipment in Small Scale AAC Block Plant

Ball Mill: Essential for milling fly ash or sand to the required fineness.

Slurry Mixer: Ensures the homogeneous mixing of various raw materials.

AAC Moulds: Where the slurry is poured to take the shape of the blocks.

Cutting Machines: These include level cutting, vertical cutting, and two – side cutting machines, which accurately shape the blocks.

Autoclave: The heart of the process, where high – temperature steam treatment occurs.

Ferry Cart: Facilitates the movement of materials and semi – products within the plant.

20,000 m³/year AAC Plant Delivered to Kenya

A Kenyan building material distributor wanted to transform from a reseller into a manufacturer. Local demand for AAC blocks was increasing due to rising real estate construction.

“The machines are stable, easy to operate, and the cutting precision is excellent. Their engineering team supported us from installation to production. This project changed our entire business.”

Project Overview

- Capacity: 20,000 m³/year

- Raw Materials: Fly ash + cement

- Investment Total: USD 160,000

- Lead Time: 55 days installation + training

- Workers Required: 8

- Land Needed: ~7,000 m²

Results

- Reached daily output within the first 10 days

- Plant achieved profitability in 11 months

- Block density and strength exceeded local competitors

- Customer expanded to 50,000 m³/year after 18 months

- We supplied the upgraded production line as well

20,000 m³/year AAC Block Plant Cost

Estimated Cost Range: USD 80,000 – 300,000

This price includes:

- Core equipment

- Moulds & side plates

- Cutting system

- Autoclave(s)

- Steam boiler

- Basic electrical systems

- Installation guidance

What Determines the Final Cost?

1. Raw Material Type

2. Automation Level

3. Number of Autoclaves

4. Cutting Machine Configuration

5. Plant Layout & Land Size

6. Local Voltage & Standards

Services You Can Get from Us

Customized AAC Block Plant Process and Layout Design:

Our experienced engineers will design a production process and plant layout that maximizes efficiency and productivity while minimizing costs.

AAC Block Machines Manufacturing and Supplying:

We provide high-quality AAC block machines.

Engineering Construction, Equipment Installation, Personnel Training:

We offer turnkey solutions that include engineering construction, equipment installation, and comprehensive personnel training. Our team will ensure that your plant is up and running smoothly in no time.

Trial production of whole AAC plant:

Before handing over the factory to you, we will conduct a trial production of the production line equipment to ensure that everything is running normally.

Hot-Sale Small Scale AAC Block Plant

50,000 m³ Small Scale AAC Block Plant

Cost: $300,000-$600,000

Delivery time: 3-4 months

Advantages: Quick return on investment, low barrier to entry, the ability to rent land for factory construction, and manageable staff size.

Suitable for: Individual entrepreneurs and small and medium-sized enterprises.

Why Choose Us as Your AAC Production Line Manufacturer?

Many suppliers claim they can provide AAC plants, but few have real technical strength and full in-house production capabilities. Here’s why clients in more than 20+ countries choose us:

✔ 100% In-House Manufacturing

All key equipment — moulds, autoclaves, cutting systems — are produced in our factory, ensuring:

- better quality

- faster delivery

- lower maintenance cost

- long-term spare parts support

✔ 20+ Years Professional AAC Engineering Experience

We provide:

- feasibility analysis

- raw material testing

- block formula guidance

- plant design layout

- installation & commissioning

- worker training

Our engineers have successfully completed AAC installations in Asia, Africa, Middle East, and South America.

✔ Customized Plant Solutions for Every Budget

Whether the customer invests:

- $80,000 (basic line)

- $150,000 (standard line)

- $250,000+ (automatic line)

We can tailor a plant that matches their market demand and business goals.

✔ Advanced Cutting Technology

Our cutting machines provide:

- smooth block surfaces

- accurate dimensions

- minimal waste

- stable output

Cutting quality directly affects block value — this is where our equipment stands out.

✔ Strong Export Experience

We have supplied AAC plants to:

India, Bangladesh, Pakistan, Vietnam, Indonesia, UAE, Saudi Arabia, Kenya, Nigeria, Egypt, Kazakhstan, Russia, Mexico, Peru, South Africa, Tanzania…

We understand different countries’ voltage, boiler standards, safety regulations, and shipping requirements.

✔ Quick Response After-Sales Service

We provide:

- video support

- remote guidance

- on-site engineer service

- spare parts supply

Most issues are solved within 24–72 hours.

Top 5 Manufacturers of Small Scale AAC Block Plant

1. Guangxi Hongfa Heavy Industry Machinery Co., Ltd.

- Main Products: AAC block/ALC wall panel making plants (with an annual output of 50,000 – 500,000 m³), concrete mixing plants, and block forming machines.

- Features: It offers customizable semi-automatic or fully automatic Small Scale AAC Block Plant, equipped with PLC control systems and compatible with 380V/220V power supplies. The products have obtained CE certification. The company provides overseas installation, commissioning, and training services, and has a short after-sales service cycle.

- Suitable Enterprise Types: Startups with limited budgets, small and medium-sized building material factories planning to expand their product portfolios, and export-oriented enterprises.

2. Henan Zhengyi Building Material Machinery Manufacturing Co., Ltd.

- Main Products: AAC block/panel manufacturing plants (annual output of 50,000 – 300,000 m³), cutting machines, and autoclaves.

- Features: The equipment adopts a modular design, and customers can optionally equip it with Siemens motors or Schneider PLCs. It is equipped with a waste heat recovery system that reduces energy consumption by 18%, and its dust emission is less than 10mg/m³. It also supports customization for alpine or seismic regions.

- Suitable Enterprise Types: Enterprises focusing on energy conservation and environmental protection, as well as manufacturers planning to enter overseas markets such as Central Asia and Russia.

3. Dongyue Machinery Group Co., Ltd.

- Main Products: AAC block/panel manufacturing plants (annual output of 50,000 – 300,000 m³).

- Features: The production lines absorb German technology and have a high level of automation. The company has nearly 500 project cases worldwide and provides one-stop services including planning, installation, commissioning, and training. Its products have obtained CE, ISO, and SGS certifications.

- Suitable Enterprise Types: Enterprises pursuing stable and efficient production and aiming to reduce operating costs, especially those suitable for large-scale replicated production.

4. Jiangsu Huilong International Co., Ltd.

- Main Products: AAC block manufacturing plants (annual output of 30,000 – 300,000 m³), cutting machines, molds, and autoclaves.

- Features: Multiple specifications of molds are available, with an hourly output ranging from 1,280 to 12,000 blocks. The company also provides factory design and automation solutions.

- Suitable Enterprise Types: Small and medium-sized enterprises with limited factory space and expecting to launch production quickly, as the equipment supports flexible capacity adjustment.

5. Henan Lanshan Machinery Manufacturing Co., Ltd.

- Main Products: Small Scale AAC block Plant.

- Features: The equipment has a small footprint and low investment, making it suitable for the initial operation stage. It also supports customized configurations.

- Suitable Enterprise Types: Individual operators or small processing plants that are entering the AAC field for the first time and face constraints in capital and site.

Get Your 20,000 m³/year AAC Plant

If you are looking to start an AAC block manufacturing business with low investment, fast ROI, and stable production, a 20,000 m³/year AAC plant is the ideal entry-level choice.

We provide:

- customized price quotation

- full project feasibility report

- plant layout design

- raw material analysis

- profit calculation

- installation guidance

👉 Contact us now to get your FREE customized proposal.

Start your AAC block business today and become the leading local supplier in your market.

Related AAC Plant

Related: AAC Block Mini Plant, Mini AAC Plant Cost, Autoclaved Aerated Concrete AAC Plant