150,000 m³/year AAC Block Line Installed in Finland

In April 2025, our company successfully installed a 150,000 m³/year AAC Block Line in Finland. As a manufacturer with 20+ years of experience and exports to 80+ countries, we provided a turnkey solution tailored to Finland’s local regulations, climate conditions, and market demand.

Client Location: Southern Finland

Plant Capacity: 150,000 m³/year

Production Scope: AAC blocks (various densities), U-blocks, partition blocks

Automation Level: Fully automatic

Energy System: Eco-friendly steam curing system adapted to Finland’s high energy-efficiency standards

End Use: Residential and commercial low-energy buildings

What Is an AAC Block Line?

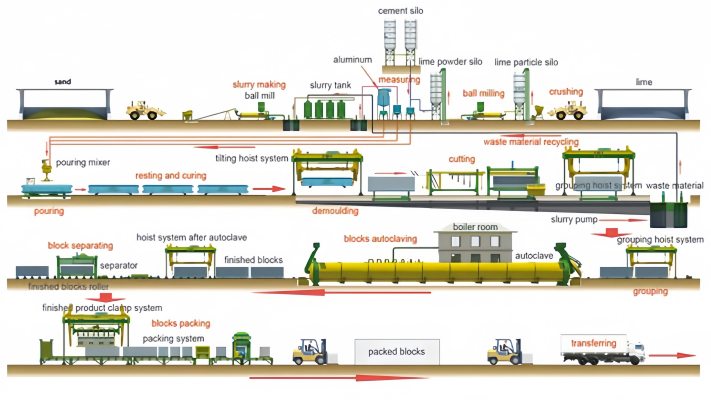

An AAC Block Line is a fully integrated production system used to manufacture Autoclaved Aerated Concrete blocks. It includes:

- Raw material dosing, storage & batching

- Mixing & pouring system

- Pre-curing

- Wire cutting machine

- Autoclaves (high-pressure steam curing)

- Tilting & separating equipment

- Packing and palletizing line

AAC blocks produced on this line are lightweight, fire-resistant, highly insulated, and ideal for cold climates like Finland.

Why a 150,000 m³/year AAC Block Line Is Ideal for Finland?

Finland’s construction sector is characterized by:

- Long winters and cold temperatures

- Strict insulation requirements (U-value, energy class)

- High labor cost

- Preference for fast, efficient building materials

- Growing demand for environmentally friendly wall systems

A 150,000 m³/year AAC plant perfectly supports:

- Regional market demand without overscaling

- Stable supply during high construction seasons

- Efficiency with reduced labor dependency

- Potential expansion to 200,000 m³/year

- Compatibility with Finland’s thermal insulation standards

Customer Requirements

The Finnish client required:

- A highly automated AAC production line to reduce labor dependence

- Consistent product density suitable for Nordic insulation standards

- Energy-efficient autoclave & steam system

- Accurate cutting machine for thin-bed construction

- Stable production in cold climate conditions

- Reliable supplier with EU-level quality standards

After evaluating suppliers from Germany, India, and China, the client selected us due to our engineering strength, global cases, and reliable after-sales support.

Main Advantages of the AAC Block Line in Finland

1. High Automation – Ideal for Finland’s Labor Market

Finland has high labor costs, making automation essential.

Our line includes:

- Automatic batching

- Automatic pouring

- Automatic cutting

- Automatic grouping and packing

This reduces operational labor by up to 40–50%.

2. Energy-Efficient Steam Curing System

Designed to minimize steam loss and fuel consumption:

- Heat recovery modules

- Optimized autoclave layout

- EU-compliant pressure vessels

- Low-temperature curing option

This ensures lower energy cost—critical for Finland’s high energy rates.

3. High-Precision Cutting Machine

Ensures:

- Smooth block surfaces

- Accurate dimensions for thin-bed mortar

- Less waste during production

- Better insulation performance

Perfect for Finnish low-energy and passive house standards.

4. Strong, Stable Product Formula

We adjusted density & strength standards specifically for Finland:

- D400 / D500 / D600 density options

- Improved thermal insulation

- Low moisture absorption

- High frost resistance

5. Easy Expansion Design

The entire line is designed for future upgrades:

- AAC panel production

- Increase to 200,000 m³/year

- More autoclaves or molds

This helps the customer scale production without rebuilding.

On-Site Installation & Training in Finland

Our engineering team provided:

- Plant layout optimization

- Installation guidance

- Worker training

- Test production running

- Quality control certification support

Within weeks, the line achieved stable daily output and consistent block quality.

What Our Client Says?

“The AAC line has significantly reduced our production cost and improved product stability. The automation level is excellent and perfectly suited to Finland’s labor conditions. The blocks meet the thermal insulation and structural requirements for Finnish construction, and the line is ready for future expansion. This project helped us quickly establish AAC supply capacity in our region.”

Why Choose Us?

- 20+ years AAC manufacturing experience

- Exported to 80+ countries

- EU-standard autoclave & pressure vessels

- Turnkey solutions from A–Z

- Customized formulas for cold regions

- Low investment cost with fast ROI

- Strong after-sales support

Looking to Build an AAC Block Manufacturing Plant?

Whether you need:

- A 50,000–600,000 m³/year AAC block manufacturing plant

- Customized block densities

- Fully automatic or semi-automatic configurations

- Turnkey engineering support

- Cost estimation for a new AAC factory

We can provide a complete solution.

👉 Contact us today for a free feasibility report and quotation.

Our engineering team will design the best AAC block manufacturing solution for your market.