The global construction industry is adopting lightweight, thermally insulating, and fire-resistant AAC blocks at an annual rate exceeding 7%. Cost control for AAC block plant determines the speed of return on investment and competitiveness.

Here, we will introduce the AAC Block Plant costs of different scales, factors that affect your profit margin, how to reduce costs to maximize profits, and calculation of return on investment.

Mini/small AAC Block Plant: 30000-100000 m3/year

Medium scale AAC Block Plant: 100000-200000 m3/year

Large AAC Block Plant: Capacity: 200000-500000 m3/year

Cost for AAC Block Plants of Different Scales

| Scale | Capacity Range | Equipment & Installation Cost | Land & Infrastructure Cost | Total Investment Range | Estimated Payback Period |

|---|---|---|---|---|---|

| Small | 30,000–100,000 m³ | $400,000–$1,000,000 | $150,000–$300,000 | $600,000–$1,300,000 | 2.0–2.5 years |

| Medium | 100,000–200,000 m³ | $1,000,000–$2,000,000 | $500,000–$800,000 | $1,500,000–$2,800,000 | 2.0–2.8 years |

| Large | 300,000–500,000 m³ | $2,000,000–$3,500,000 | $800,000–$1,500,000 | $2,800,000–$5,000,000 | 2.5–3.5 years |

The payback period is estimated based on a net profit margin of 25–30%. The actual period is subject to fluctuations in market prices, capacity utilization rate, and cost control efficiency.

10 Factors Effecting the AAC Block Plant Cost

When planning an AAC block plant investment, the following 10 factors directly affect the project’s profitability:

1. Production Scale and Process

The process route determines initial investment: While the autoclaving process has higher equipment costs, it meets product strength standards and can obtain international certification, making it suitable for the high-end market. The non-autoclaving process reduces equipment costs by 60%, but is limited by strength performance and certification requirements and is only suitable for regional, low-end demand.

2. Raw Material Formulation Differences

The raw material system directly impacts cost: Fly ash-based formulations have the lowest cost, followed by sand-based formulations, and slag-based formulations have the highest cost due to their higher equipment requirements. The price difference between the three raw materials can reach $5–12 per cubic meter, so the choice should be based on local raw material conditions.

3. Automation Level Configuration

A semi-automated AAC production line can save 20% on initial investment, but requires 8–10 additional workers per shift, resulting in high long-term labor costs. A fully automated production line (including robotic palletizing) requires an additional investment of $150,000–200,000, but reduces labor costs by 70%, with the difference recouped in 3–5 years.

4. Core Equipment Costs

Using a medium-sized plant with a 150,000 m³/Y as an example:

- Jaw crusher + ball mill: $60,000–80,000

- High-precision cutting machine: $75,000–100,000

- Two Ø2m × 27m autoclaves: $300,000–400,000

- 10t/h steam boiler: $30,000–50,000

- Automatic batching + packaging + robotic palletizing system: $150,000–250,000

5. Land Costs

A site of 13,000–33,000 m² is required. A site near a power plant (to obtain fly ash) or a port (to reduce sand/slag transportation costs) can reduce logistics costs by 5–8%, significantly optimizing long-term operating costs.

6. Utility Support

Includes a 315kVA substation, a 150m³/day water circulation system, and 2t/h compressed air equipment. The cost of renovation or new construction should be assessed based on local infrastructure conditions.

7. Environmental Protection and Safety Investment

Dust collectors, noise protection enclosures, and a waste slurry recovery system will cost approximately $50,000–$100,000 to ensure compliance with emission standards, avoid environmental penalties, and help pass the environmental impact assessment on the first try.

8. Permit and Compliance Fees

This covers environmental impact assessment reports, production licenses, green building material certifications, and other costs, costing approximately $5,000–$10,000, and is a prerequisite for legal project operations.

9. Working Capital Reserves

A 45–60-day inventory of raw materials and finished products, approximately 15% of the total investment, should be reserved to ensure production continuity.

10. Other Necessary Reserves

This includes equipment insurance, technical training, spare parts, initial marketing and promotional expenses, and unforeseen expenses. We recommend setting aside 8–10% of the total investment to address unexpected situations during project implementation.

By calculating the above factors in detail, we can accurately identify the cost optimization space and transform every investment into competitiveness.

How to Reduce the AAC Block Plant Cost

Sourcing Raw Materials Locally

Restricting fly ash transportation to within an 80-kilometer radius reduces costs by $6–8 per cubic meter. This also ensures long-term partnerships with production locations, stabilizes supply, and controls prices.

Annual Equipment Maintenance Package

Signing a three-year, all-inclusive maintenance package with the manufacturer reduces unexpected downtime costs by 40%, increases equipment utilization to over 90%, and minimizes production losses.

Efficient Energy Utilization

Off-peak electricity consumption saves 20%, and autoclave exhaust steam is recycled back into the boiler, saving 8–12% annually in natural gas. Combined, these two strategies result in 15–25% annual energy savings.

How to Calculate Return on Investment

- Collect key financial data: including total investment (initial capital), annual production, price per block, profit margin, and operating costs.

- Calculate annual revenue: Annual revenue = Annual production × Price per block.

- Calculate annual net profit: This can be calculated by subtracting operating costs from annual revenue or multiplying annual revenue by profit margin.

- Calculate return on investment (ROI): Return on investment (%) = (Annual net profit / Total investment) × 100.

- Calculate payback period (optional): Payback period (years) = Total investment / Annual net profit.

For example, assuming a total investment of $3 million, annual production of 600,000 blocks, a selling price of $8 per block, a profit margin of 30%, and operating costs of $3.36 million, this results in annual revenue of $4.8 million, annual net profit of $1.44 million, a 48% return on investment, and a payback period of 2.08 years.

3 Hot-Sale AAC Block Plant Cost

Mini AAC plant with 50,000m³/year

Equipment: $600,000 USD

Factory with steel structure: $150,000USD

Total cost: $900,000 USD

Payback period: 18 months

Medium-sized plant with 200,000m³/year

Equipment: $1.8 million USD

Factory : $500,000 USD

Land: $300,000 USD

Payback period: 24 months

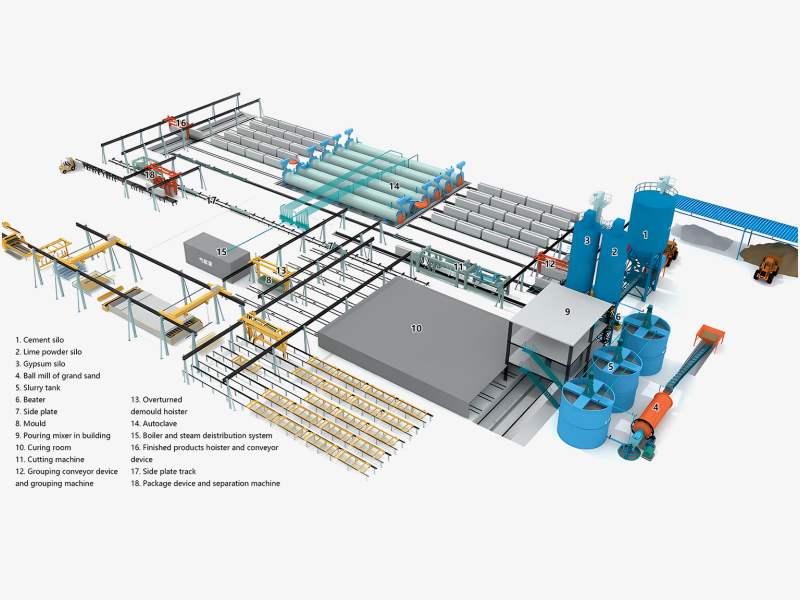

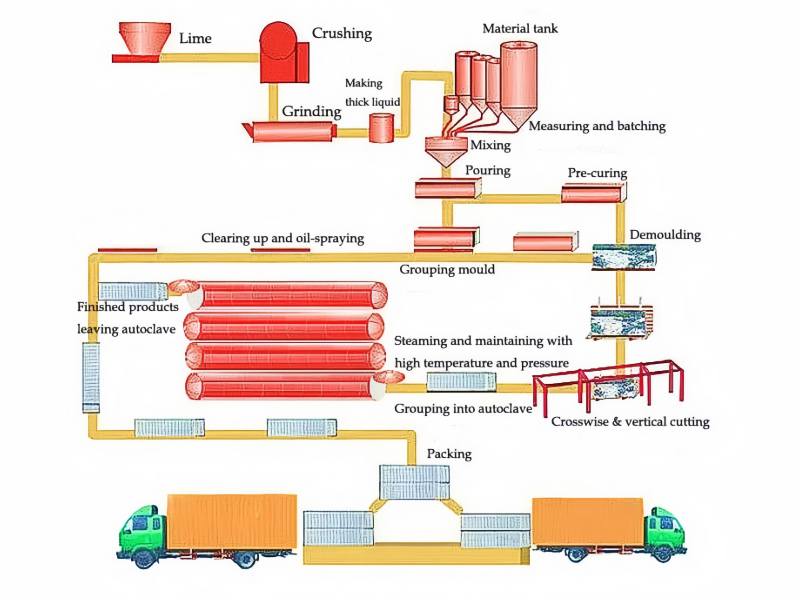

AAC Block Manufacturing Process

Raw material process → Batching and Mixing → Pouring → Static pre-curing → Cutting → Autoclaving Curing → Finished product Processing

1. Raw Material Processing: Sand is crushed and ground to the desired fineness. Cement, lime, and gypsum are stored in silos, and aluminum powder is mixed with water to form an aluminum slurry.

2. Batching and Mixing: The various raw materials are weighed according to precise proportions and then thoroughly mixed in a mixer to form a uniform slurry.

3. Pouring: The mixed slurry is poured into steel molds. The size and shape of the molds can be designed to meet the desired block specifications.

4. Static Pre-curing: The molds containing the slurry are transported to a pre-curing area where the slurry gradually hardens under suitable temperature and humidity conditions to achieve initial strength. This process typically takes several hours.

5. Cutting: After the slurry is pre-cured, it is cut into the desired size and shape using high-precision cutting equipment, steel wire or blades.

6. Autoclave Curing: Blocks are placed in an autoclave and cured for several hours at temperatures of 175-200°C and pressures of 10-15 bar, significantly enhancing the blocks’ strength and durability.

7. Finished Product Processing: After autoclave curing, the blocks are removed from the autoclave and transported to a storage area. After inspection and packaging, they are ready for shipment.

Machinery in AAC Block Manufacturing

1. Raw Material Handling Equipment

Ball Mill: Used for finely crushing siliceous and calcareous materials such as sand, fly ash, and lime.

Jaw Crusher: Crushes bulky raw materials (such as limestone) in preparation for subsequent grinding.

2. Mixing and Batching System

Mixer: Commonly used is a vertical shaft mixer, which uniformly mixes siliceous and calcareous materials, gas-generating agents (aluminum powder), and conditioning agents (gypsum) to ensure consistent block quality.

Batching System: Accurately measures and controls the raw material input ratio to ensure that block properties such as strength, density, and porosity meet specified standards.

3. Molding and Casting Equipment

Molds: Made of steel and designed to fit the block size, they hold the mixed slurry and shape it.

Pouring Equipment: Ensures smooth transfer of slurry to the mold, preventing air bubbles and uneven distribution.

4. Curing and Hardening Equipment

Pre-curing Chamber: Allows the slurry to initially solidify and strengthen in a controlled temperature and humidity environment, preparing it for subsequent processing.

Autoclave: A large pressure vessel that uses high-temperature, high-pressure steam curing to induce chemical reactions in the raw materials, forming a strong and stable structure and enhancing the strength and durability of the blocks.

5. Cutting and Finishing Equipment

Cutting Machine: Cuts the pre-cured blocks horizontally and vertically (e.g., using a wire saw) to ensure dimensional accuracy.

Finishing Equipment: Optimizes the surface smoothness of the blocks through processes such as grinding to meet both aesthetic and functional requirements.

Challenges and Solutions in Aerated Concrete Block Production

Challenges

1. High initial investment, requiring significant capital investment in equipment, land, and infrastructure.

2. Production relies on precise chemical reactions and curing processes, requiring a skilled workforce.

3. Intense market competition, facing pressure from both established brands and new entrants.

4. Fluctuating raw material costs directly impact production profits.

Solutions

1. Apply for government subsidies, bank loans, and fiscal incentives to mitigate initial investment pressures.

2. Provide regular training to enhance worker skills and ensure production efficiency.

3. Increase promotional investment, adhere to high-quality standards, and enhance market competitiveness.

4. Establish long-term partnerships with suppliers and sign fixed contracts to stabilize raw material costs and supply.