A medium scale AAC plant refers to an autoclaved aerated concrete production line with an annual output of 100,000m³ to 200,000 m³. Our Medium Scale AAC Plant Cost ranges from $1 million to $3 million.

For entrepreneurs seeking a balance between small-scale and large-scale operations, medium-sized AAC plants have become a promising option.

What Is the Cost of the Medium Scale AAC Plant

The cost of a medium-scale AAC plant is influenced by several factors, including production capacity, level of automation, and equipment quality. Generally speaking, the total investment for a medium-sized AAC plant with an annual production capacity of 100,000 to 200,000 cubic meters ranges from US$1 million to US$3 million.

Semi-automated medium-scale AAC plant (turnkey): US$1.2–1.6 million

Fully automated medium-scale AAC plant (turnkey): US$1.7–2.3 million

For overseas EPC services including installation, add an additional 10–15%

Technical Parameters of Medium AAC Production Line

Automation Level: Semi-automatic and fully automatic.

Daily Output: 330m³ to 650 m³(8-16 hours of operation)

Finished Product Density: 400 to 650 kg/m³ (B04-B06 grades)

Cutting Accuracy: ±1 mm

Autoclave Curing: 180 to 200°C, 1.0 to 1.3 MPa, 8 hours

Installed Power: 800 to 1200 kW

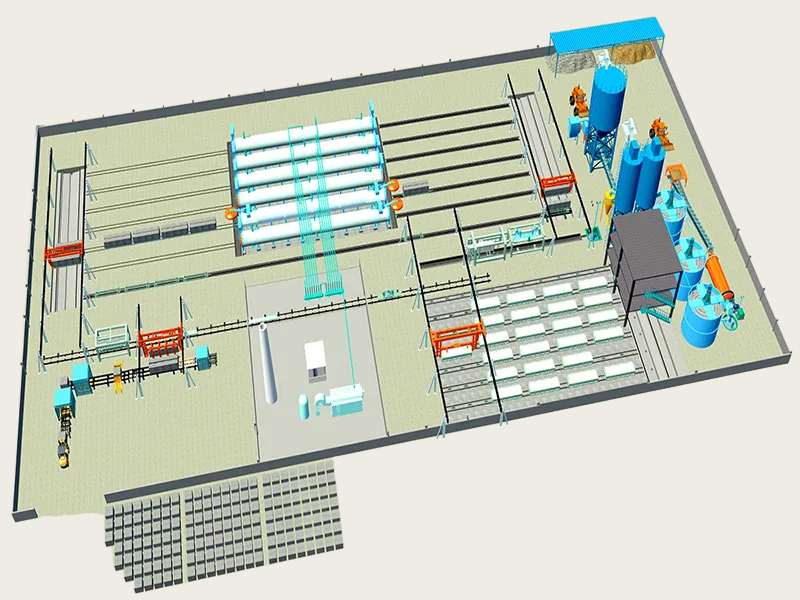

Occupancy: 8,000 to 12,000 m²

Power Consumption: 1,000 to 2,000 kW

Voltage Requirement: 380 to 440 V, compatible with standard industrial power supplies.

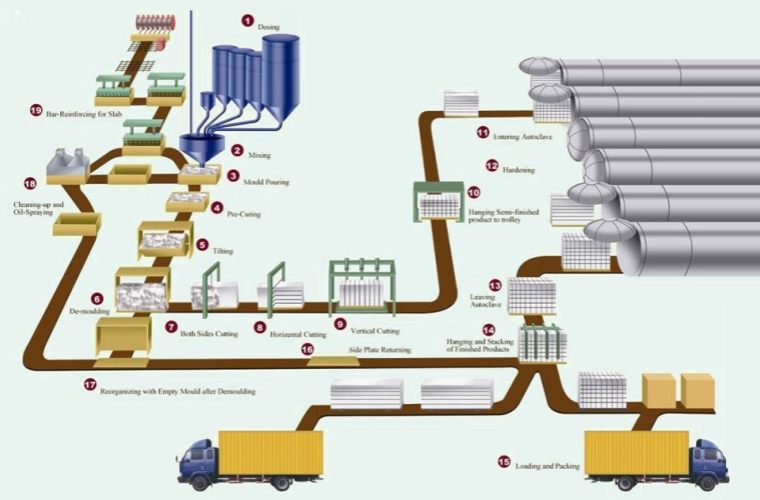

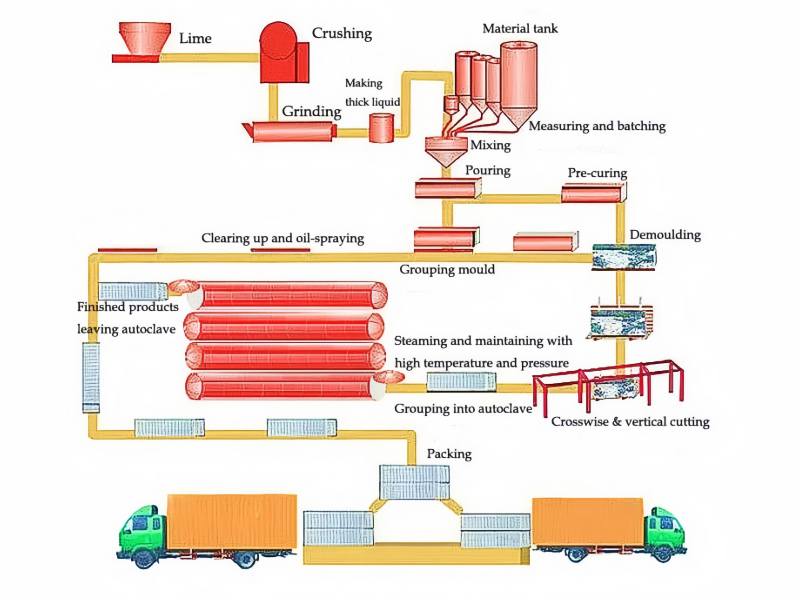

Production Process of Medium Scale AAC Plant

The production process for a medium-sized AAC plant is essentially similar to that of a small plant, but with higher efficiency and capacity.

1. Raw Material Preparation and Grinding: Raw materials such as fly ash (or sand), lime, and cement are crushed and ground into a fine powder.

2. Batching and Mixing: The ground raw materials, water, and aluminum powder (as a foaming agent) are metered and mixed in a large-capacity mixer.

3. Pouring and Foaming: The mixture is poured into large molds where it foams. The mixture expands to nearly double its original volume, forming a honeycomb structure.

4. Pre-Curing: The molds containing the foamed mixture are moved to a pre-curing area for 3-4 hours, allowing the mixture to solidify into a semi-solid state and be ready for cutting.

5. Cutting: The blocks are removed from the molds and cut to precise sizes using a cutting machine.

6. Autoclaving: The cut blocks are placed in an autoclave and processed at a high temperature of 180-200°C and a high pressure of 1.0-1.3 MPa for 8-12 hours.

7. Packaging and Storage: The finished blocks are packaged using automated packaging machines and stored in a designated area awaiting shipment.

Equipment of Medium Scale AAC Plant

Crushing and Grinding Equipment

Jaw crushers and ball mills are used to crush and grind raw materials to the desired fineness.

Batching and Mixing Equipment

Weighing batchers (for precise metering) and high-speed mixers (to ensure thorough mixing of raw materials).

Molds and Mold Transporters

Large molds made of high-quality steel, along with transporters for easy mold transportation during production.

Cutting Equipment

Advanced multi-wire sawing machines for high-precision cutting of large blocks into various sizes.

Autoclaves

Large-capacity equipment capable of processing large batches of blocks, enabling efficient steam curing.

Conveying and Handling Systems

A network of conveyors, cranes, and forklifts transports raw materials, molds, and finished products, streamlining the process.

Advantages of a Medium-Sized AAC Plant

- Balanced Production Capacity: A medium-sized plant’s production capacity is neither too small to limit market reach nor too large to be unmanageable.

- Scalability: Adding an additional reactor can reach 300,000 m³.

- Moderate Manpower: 25–30 people can operate.

- Flexibility and Adaptability: They can adapt to changes in market demand better than large plants.

- Better Profit Margins: With higher output and lower unit costs, medium-sized plants have the potential to achieve better profit margins than small plants.

Cost Breakdown for Medium Size AAC Factory Project

Taking a 150,000 m³/year semi-automatic production line built in Asia as an example.

| Cost Item | USD (Ten Thousand) | Description |

|---|---|---|

| 1. Land & Infrastructure | 250,000 to 350,000 | Rental of 10,000 ㎡ + steel structure workshop + roads |

| 2. Equipment & Installation | 850,000 to 1,000,000 | Including cutting machines, autoclaves, boilers, and training |

| 3. Raw Material Working Capital | 80,000 to 120,000 | 60-day inventory (fly ash, lime, cement, aluminum powder) |

| 4. Labor (First Year) | 60,000 to 90,000 | 25–30 personnel, average USD 400 per month |

| 5. Utilities (First Year) | 90,000 to 130,000 | Electricity 1.2 million kWh, water 40,000 ㎡, natural gas 800,000 ㎡ |

| 6. Licensing & Compliance | 20,000 to 40,000 | Environmental assessment, boiler certification, product certification |

| 7. Miscellaneous | 30,000 to 50,000 | Spare parts, insurance, trial operation |

| Total | ≈ 1,400,000 to 1,800,000 | Turnkey solution enabling immediate brick production after handover |

10 Factors Effecting the Medium Scale AAC Plant Cost

Production Capacity:

Higher production capacity requires more equipment and larger infrastructure, leading to increased costs.

Automation Level:

The degree of automation significantly impacts costs. Fully automated plants are more expensive but more efficient.

Location:

Land costs, construction costs, and utility rates vary by location, affecting the overall cost of a plant.

Equipment Quality and Brand:

High-quality equipment from reputable manufacturers is more expensive but offers greater reliability and a longer lifespan.

Raw Material Availability:

Proximity to raw material sources reduces transportation costs, impacting the overall cost of a plant.

Medium Scale AAC Plant VS. Large AAC Plant

Initial Investment: The initial investment for a medium-sized AAC plant is significantly lower than that for a large plant.

| Indicator | Medium-sized (150,000 m³) | Large-sized (300,000 m³) |

|---|---|---|

| Total Investment | 1.4–1.8 million USD | 2.8–3.4 million USD |

| Payback Period | 18–24 months | 24–30 months |

| Energy Consumption per Unit | 30 kWh/m³ | 27 kWh/m³ |

| Number of Employees | 25–30 personnel | 50–60 personnel |

| Expansion Method | Adding one autoclave line | Need to build new workshops |

| Market Radius | 300 km | Over 500 km |

In addition, medium-sized factories have lower risks than large factories. Lower initial investment means less financial risk, and they are more flexible to adapt to market changes.

How to Reduce the Medium AAC Bricks Plant Cost

- Install four reactors initially, adding two more later.

- Initially use national standard electronic controls, then upgrade to CE components once cash flow stabilizes.

- Lease land and build-operated-transfer boilers, saving an additional 10% on down payments.

- Sign a 10-year, long-term contract with a power plant for fly ash at $0-3/t.

- Apply for green bonds, with interest rates 1-2% lower than the benchmark.

ROI of Medium-Sized AAC Plants

Due to economies of scale, medium-sized AAC plants generally offer higher ROI potential than small plants. A plant can begin generating profits within 18-24 months of operation.

Profitability is influenced by factors such as production efficiency, raw material costs, and the market price of AAC blocks. The ROI typically ranges from 15% to 25% per year.