A 30,000 m3/year AAC block plant is a compact Autoclaved Aerated Concrete production line designed to produce lightweight, high-performance AAC blocks for local construction markets. Although categorized as a small-scale AAC plant, it includes every key process required to manufacture premium AAC blocks, such as raw material batching, slurry mixing, casting, cutting, autoclaving, and packaging.

This plant model is ideal for:

- Investors starting their first AAC block business

- Local construction companies expanding into building materials

- Regions with developing AAC demand

- Markets transitioning from clay bricks or normal concrete blocks

- Countries with growing affordable housing programs

Capacity: 30,000 m³/year

Autoklaf: 3-4

End product: AAC Block/Panels

Sesuai untuk: pembekal bahan binaan kecil

Standard: Cina, ASME, EU dan lain-lain

Gred Automasi: Separa automatik, Automatik Sepenuhnya

Bahan Bata: Abu Terbang/Pasir

Dimensi Bata: disesuaikan

Sijil: ISO 9001

30,000 m3/Year AAC Block Plant Price

The total investment depends on:

- Type of raw materials (fly ash or sand)

- Cutting machine level (standard or high-precision)

- Autoclave size and quantity

- Automation grade

- Country destination

- Shipping and installation requirements

⭐ Typical Price Range: 100,000 – 350,000 USD

| Item | Cost Range (USD) |

|---|---|

| Full equipment set | 100,000 – 260,000 |

| Shipping costs | 10,000 – 40,000 |

| Installation & commissioning | 10,000 – 25,000 |

| Auxiliary machines (boiler, air compressor) | 20,000 – 50,000 |

This makes the 30,000 m³/year AAC plant the most budget-friendly AAC block manufacturing solution available.

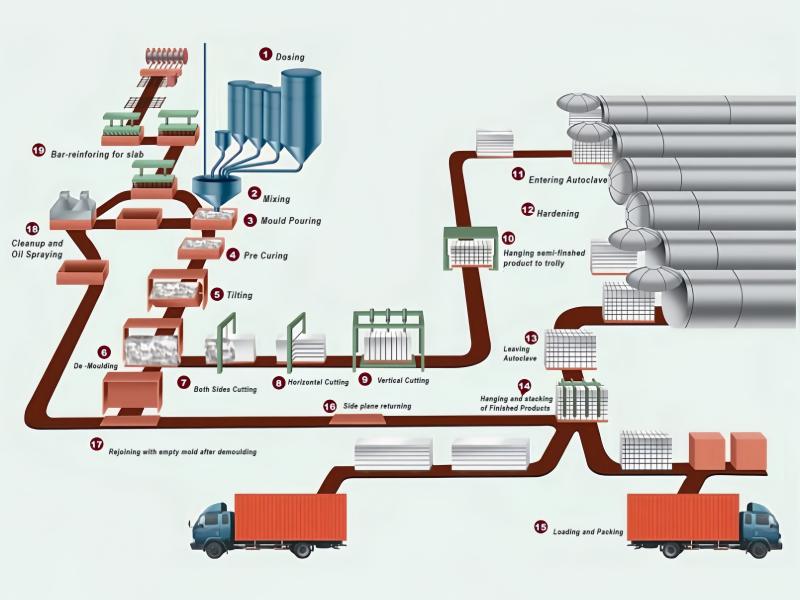

Process of 20,000 m³/year AAC Block Plant

Below is the complete workflow used in small AAC plants.

Step 1 — Raw Material Storage & Batching

Cement, lime, gypsum, fly ash/sand are stored in silos or ground storage and fed into weighing systems.

Step 2 — Slurry Mixing

Materials are blended into slurry using a high-efficiency mixer. Aluminum powder is added precisely to ensure correct density and strength.

Step 3 — Casting

Slurry is poured into moulds. Rising and foaming occur naturally during pre-curing.

Step 4 — Pre-Curing (2–3 hours)

The “green cake” becomes semi-solid and ready for demoulding.

Step 5 — Demoulding & Tilting

The mould is tilted 90 degrees, and the green body is separated from the mould.

Step 6 — Cutting

The green cake is cut horizontally and vertically into precise block sizes. Block tolerance is usually ±1.5mm to ±3mm, depending on the cutting system.

Step 7 — Autoclaving (8–12 hours)

Blocks are loaded into autoclaves and cured using saturated steam at 1.2–1.4 MPa.

This process ensures high compressive strength (3.0–4.5 MPa).

Step 8 — Block Packing

Finished blocks are separated, stacked, and packed for delivery.

Key Advantages of a 30,000 m³/year AAC Block Plant

Even though this production line belongs to the “mini” AAC plant category, it delivers powerful advantages:

✔ 1. Low Investment & Fast ROI

The 30,000 m³/year AAC plant has the lowest entry cost among all AAC lines.

Typical benefits include:

- Lower equipment investment

- Reduced civil construction cost

- Lower electricity and labor requirements

- ROI typically within 8–18 months

- Minimum operational risks

This makes it a perfect option for first-time investors.

✔ 2. Lower Operating Cost

A 20,000 m³/year AAC plant typically requires:

- 5–10 workers

- smaller autoclaves (Φ2×20m or Φ2×22m)

- low energy consumption

- compact land area (5,000–9,000 m²)

- lower steam and electricity cost

This reduces monthly operational expense and gives higher profit margins.

✔ 3. Easy to Operate & Maintain

A 30,000 m³/year AAC plant is simple in structure:

- Fewer machines

- Straightforward production flow

- Lower skill requirements

- Easy training for workers

- Fewer maintenance tasks

This significantly reduces downtime and improves productivity.

✔ 4. Suitable for Local & Regional Supply Markets

In regions where AAC is still developing, this capacity perfectly matches early-stage market demand:

- Supplies local construction sites

- Supports contractors and building material stores

- Ensures stable sales without overproduction

Many successful AAC companies start with this capacity and later expand to 60,000–100,000 m³/year. It is suitable for markets where demand is growing but not large enough for high-capacity plants.

✔ 5. Upgradeable Production Capacity

The entire line can be upgraded in the future:

- Add additional autoclaves

- Upgrade the cutting system

- Add higher automation

- Expand raw material processing section

This allows investors to gradually enlarge production without rebuilding the plant.

Main Equipment in Mini AAC Block Plant

Kilang Bola: Penting untuk mengisar abu terbang atau pasir kepada kehalusan yang diperlukan.

Pengadun Buburan: Memastikan pencampuran homogen pelbagai bahan mentah.

Acuan AAC: Di mana buburan dituangkan untuk mengambil bentuk bongkah.

Mesin Pemotong: Ini termasuk pemotongan aras, pemotongan menegak dan mesin pemotong dua sisi, yang membentuk bongkah dengan tepat.

Autoklaf: Inti proses, di mana rawatan wap suhu tinggi berlaku.

Kereta Feri: Memudahkan pergerakan bahan dan separa produk dalam kilang.

30,000 m³/year AAC Block Plant to Kenya

In 2024, we successfully delivered a 30,000 m³/year AAC plant to a client in Nairobi, Kenya.

“We are impressed with the equipment quality and the quick production start. The cutting accuracy is excellent, and your team provided full support. We plan to expand to 60,000 m³/year soon.”

Perkhidmatan Yang Anda Boleh Dapatkan daripada Kami

Customized AAC Block Plant Process and Layout Design:

Jurutera kami yang berpengalaman akan mereka bentuk proses pengeluaran dan susun atur loji yang memaksimumkan kecekapan dan produktiviti sambil meminimumkan kos.

Pembuatan dan Pembekal Mesin Blok AAC:

Kami menyediakan mesin blok AAC berkualiti tinggi.

Pembinaan Kejuruteraan, Pemasangan Peralatan, Latihan Kakitangan:

Kami menawarkan penyelesaian turnkey yang merangkumi pembinaan kejuruteraan, pemasangan peralatan dan latihan kakitangan yang komprehensif. Pasukan kami akan memastikan kilang anda beroperasi dan berjalan lancar dalam masa yang singkat.

Pengeluaran percubaan seluruh loji AAC:

Sebelum menyerahkan kilang kepada anda, kami akan menjalankan pengeluaran percubaan peralatan barisan pengeluaran untuk memastikan semuanya berjalan seperti biasa.

Hot-Sale Small Scale AAC Block Plant

50,000 m³ Small Scale AAC Block Plant

Cost: $300,000-$600,000

Delivery time: 3-4 months

Advantages: Quick return on investment, low barrier to entry, the ability to rent land for factory construction, and manageable staff size.

Suitable for: Individual entrepreneurs and small and medium-sized enterprises.

Why Choose Us as Your AAC Production Line Manufacturer?

Many suppliers claim they can provide AAC plants, but few have real technical strength and full in-house production capabilities. Here’s why clients in more than 20+ countries choose us:

✔ 100% In-House Manufacturing

All key equipment — moulds, autoclaves, cutting systems — are produced in our factory, ensuring:

- better quality

- faster delivery

- lower maintenance cost

- long-term spare parts support

✔ 20+ Years Professional AAC Engineering Experience

We provide:

- feasibility analysis

- raw material testing

- block formula guidance

- plant design layout

- installation & commissioning

- worker training

Our engineers have successfully completed AAC installations in Asia, Africa, Middle East, and South America.

✔ Customized Plant Solutions for Every Budget

Whether the customer invests:

- $80,000 (basic line)

- $150,000 (standard line)

- $250,000+ (automatic line)

We can tailor a plant that matches their market demand and business goals.

✔ Advanced Cutting Technology

Our cutting machines provide:

- smooth block surfaces

- accurate dimensions

- minimal waste

- stable output

Cutting quality directly affects block value — this is where our equipment stands out.

✔ Strong Export Experience

We have supplied AAC plants to:

India, Bangladesh, Pakistan, Vietnam, Indonesia, UAE, Saudi Arabia, Kenya, Nigeria, Egypt, Kazakhstan, Russia, Mexico, Peru, South Africa, Tanzania…

We understand different countries’ voltage, boiler standards, safety regulations, and shipping requirements.

✔ Quick Response After-Sales Service

We provide:

- video support

- remote guidance

- on-site engineer service

- spare parts supply

Most issues are solved within 24–72 hours.

Top 5 Manufacturers of Mini AAC Block Plant

1. Guangxi Hongfa Heavy Industry Machinery Co., Ltd.

- Main Products: AAC block/ALC wall panel making plants (with an annual output of 50,000 – 500,000 m³), concrete mixing plants, and block forming machines.

- Features: It offers customizable semi-automatic or fully automatic Small Scale AAC Block Plant, equipped with PLC control systems and compatible with 380V/220V power supplies. The products have obtained CE certification. The company provides overseas installation, commissioning, and training services, and has a short after-sales service cycle.

- Suitable Enterprise Types: Startups with limited budgets, small and medium-sized building material factories planning to expand their product portfolios, and export-oriented enterprises.

2. Henan Zhengyi Building Material Machinery Manufacturing Co., Ltd.

- Main Products: AAC block/panel manufacturing plants (annual output of 50,000 – 300,000 m³), cutting machines, and autoclaves.

- Features: The equipment adopts a modular design, and customers can optionally equip it with Siemens motors or Schneider PLCs. It is equipped with a waste heat recovery system that reduces energy consumption by 18%, and its dust emission is less than 10mg/m³. It also supports customization for alpine or seismic regions.

- Suitable Enterprise Types: Enterprises focusing on energy conservation and environmental protection, as well as manufacturers planning to enter overseas markets such as Central Asia and Russia.

3. Dongyue Machinery Group Co., Ltd.

- Main Products: AAC block/panel manufacturing plants (annual output of 50,000 – 300,000 m³).

- Features: The production lines absorb German technology and have a high level of automation. The company has nearly 500 project cases worldwide and provides one-stop services including planning, installation, commissioning, and training. Its products have obtained CE, ISO, and SGS certifications.

- Suitable Enterprise Types: Enterprises pursuing stable and efficient production and aiming to reduce operating costs, especially those suitable for large-scale replicated production.

4. Jiangsu Huilong International Co., Ltd.

- Main Products: AAC block manufacturing plants (annual output of 30,000 – 300,000 m³), cutting machines, molds, and autoclaves.

- Features: Multiple specifications of molds are available, with an hourly output ranging from 1,280 to 12,000 blocks. The company also provides factory design and automation solutions.

- Suitable Enterprise Types: Small and medium-sized enterprises with limited factory space and expecting to launch production quickly, as the equipment supports flexible capacity adjustment.

5. Henan Lanshan Machinery Manufacturing Co., Ltd.

- Main Products: Small Scale AAC block Plant.

- Features: The equipment has a small footprint and low investment, making it suitable for the initial operation stage. It also supports customized configurations.

- Suitable Enterprise Types: Individual operators or small processing plants that are entering the AAC field for the first time and face constraints in capital and site.

Get Your 30,000 m³/year AAC Plant

If you are looking to start an AAC block manufacturing business with low investment, fast ROI, and stable production, a 30,000 m³/year AAC plant is the ideal entry-level choice.

We provide:

- customized price quotation

- full project feasibility report

- plant layout design

- raw material analysis

- profit calculation

- installation guidance

👉 Contact us now to get your FREE customized proposal.

Start your AAC block business today and become the leading local supplier in your market.

Loji AAC Berkaitan

Related: Mini AAC Plant Cost, Loji AAC Konkrit Berudara Autoklaf, Loji Pembuatan Blok AAC