How Much Does AAC Plant Setup Cost?

AAC Plant Setup Cost is key to investing in an AAC (Autoclaved Aerated Concrete) plant. The core factors determining AAC Plant Setup Cost include plant size (production capacity), equipment automation level, land and location costs, raw material supply and local adaptation needs, as well as compliance and infrastructure investment.

We’ve simplified costs into three categories to match your budget and market demand:

| Plant Size | Capacity Range (CBM/Year) | Setup Cost Range | Best For |

| Mini AAC Plant | 30,000 – 100,000 | 100,000 to 1,000,000 USD | New investors, local markets |

| Medium AAC Plant | 100,000 – 200,000 | 1,200,000 to 2,300,000 USD | Growing demand, regional supply |

| Large AAC Plant | 200,000- 600,000+ | 2,000,000 to 3,000,000 USD | National markets, high-volume sales |

Various Capabilities to Meet Your Needs

According to production capacity, AAC Plant can be divided into small, medium and large scale.

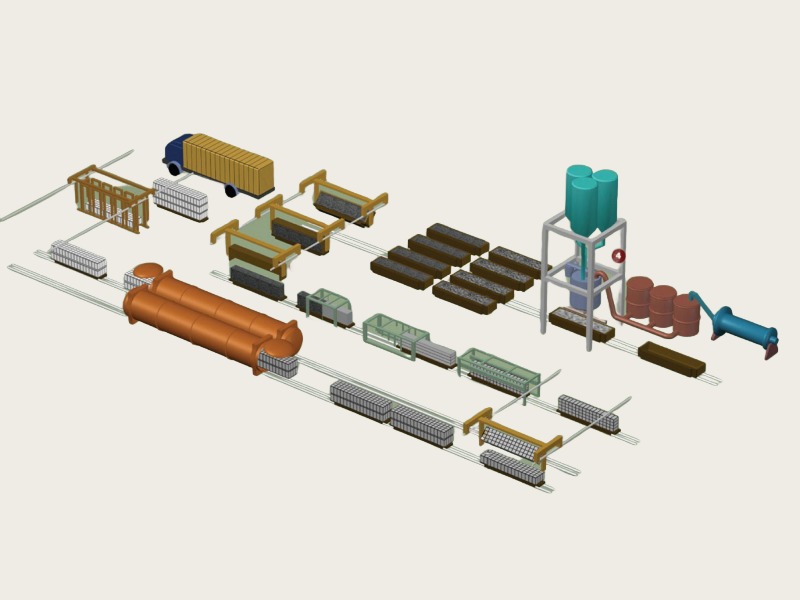

Mini/small AAC Plant

Capacity: 30000-100000 m3/year

Autoklaf: 1-3 sets

Factory: about 4000-10000m2

Types: semi-automatic/ fully automatic

Features: low initial investment, high flexibility.

Suitable for: Start-ups or enterprises with limited investment and small market demand.

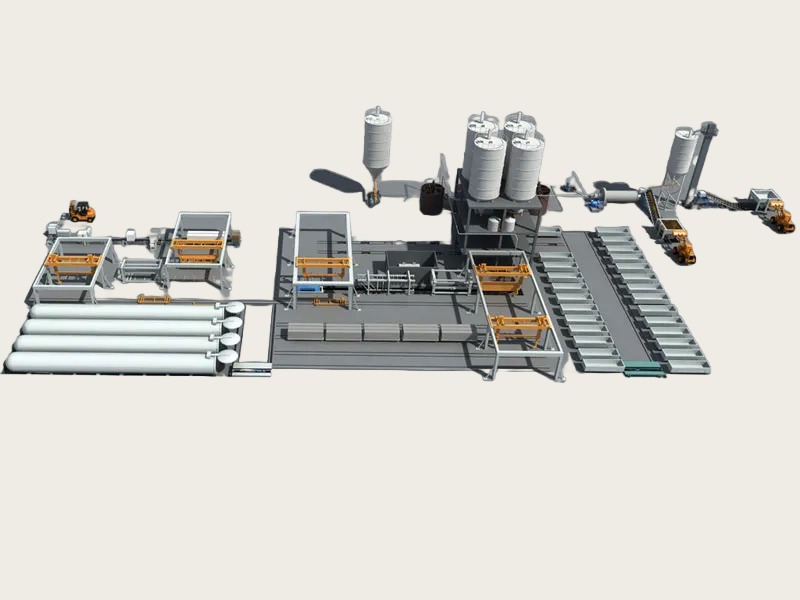

Skala sederhana AAC Plant

Capacity: 100000-200000 m3/year

Autoklaf: 4-8 sets

Factory: about 10000-20000m2

Type: fully automatic

Features: stable production capacity, controllable costs, flexibility, large-scale production, etc.

Suitable for: Enterprises with a certain market share and stable demand.

Turn-Key Price List of AAC Plant

As a professional AAC plant supplier, our turn-key packages cover end-to-end services with no hidden fees: full equipment manufacturing, overseas on-site erection, commissioning, operator training, and a 1-year spare parts supply—all core services are included upfront.

Below is a detailed cost breakdown for our autoclaved aerated concrete (AAC) plants, with annual outputs ranging from 30,000 m³ to 600,000 m³. We also offer fully customized solutions to match your exact annual production needs.

| Annual Output | Automation Level | Core Equipment (Manufactured In-House) | FOB China Price | Pay-Back Period |

| 30,000 m³ | Semi-automatic | 2 × Ø2 × 31 m Autoclaves (Our Patented Design) + Crusher + Mixer | US $280,000 | 8 months |

| 100,000 m³ | Semi-automatic | 4 × Ø2 × 31 m Autoclaves + Double-Shaft Mixer + Cutting Machine | US $850,000 | 10 months |

| 100,000 m³ | Fully automatic | 4 Autoclaves + Robot Packaging System + PLC Control Panel | US $1,300,000 | 12 months |

| 200,000 m³ | Fully automatic | 8 Autoclaves + Double Cutting Line + Steam Recovery System | US $1,900,000 | 10 months |

| 300,000 m³ | Fully automatic | 10 Autoclaves + High-Efficiency Mixer + Energy-Saving Boiler | US $2,400,000 | 9 months |

| 600,000 m³ | Fully automatic | 16 Autoclaves + 22h Double-Shift Configuration + Intelligent Monitoring System | US $3,800,000 | 10 months |

Calculated at 80% capacity (industry average utilization) and US $18 net profit per m³ – based on our global customer’s actual sales data

What’s Included in the Setup Cost?

Many investors only consider machinery, but full setup requires covering every step of production. Our turn-key packages include all essential items to get you up and running:

- Raw Material Prep Equipment: Crushers, ball mills, and material storage systems (critical for fly ash/cement handling).

- AAC Production Core: Autoclaves (150k–200k each), batching/mixing plants (50k–80k), and cutting machines (75k–100k).

- Support Systems: Boilers (30k–50k), hydraulic conveyors (40k–60k), and automated packaging lines (60k–90k).

- Safety & Compliance: Fire safety systems, dust collectors, and low-NOx burners (to meet global emission rules).

- Infrastructure: Basic factory flooring, utility connections (water/electricity), and raw material storage yards.

- Training: On-site training for your team (in local languages) to operate equipment safely.

Hidden Costs to Include in Your AAC Plant Budget

As an experienced AAC plant manufacturer, we understand many clients overlook critical extra costs that create budget gaps. To help you avoid this, we’re outlining the typical additional investment you’ll need.

| Cost Item | Approx. (USD) | Purpose (Compliant with Global Standards) |

| Low-NOx Boiler Upgrade (≤30 mg/Nm³) | 120,000 | Meets EU EN 15502, US EPA, and Indian CPCB emission rules – mandatory for most countries |

| High-Voltage Cable Trenches + Transformer Room | 80,000 | Powers our AAC production line equipment (380V/415V, 3-phase) – designed by our electrical engineers |

| Closed-Loop Water Pool + Piping | 60,000 | Reduces water consumption by 60% (our plant design feature) – aligns with environmental regulations |

| Fire-Fighting System & Approval | 40,000 | Complies with local fire codes (we provide fire safety drawings for approval) |

| Environmental & Building Permits | 30,000 | Covers legal paperwork (our team assists with document preparation for local authorities) |

| On-Site Erection Insurance | 20,000 | Protects our engineers and your site during installation (we arrange coverage via global insurers) |

| First-Year Spare Parts Buffer | 20,000 | Includes cutting wires, mould liners, and sensors (all manufactured in our factory – fast replacement) |

| 1-Month Raw Material Stock | 300,000 | Cement, lime, fly-ash, and aluminum powder (we share trusted local supplier contacts to lower costs) |

Key Factors That Affect Your Setup Cost

Not all AAC plants cost the same, these variables will adjust your budget:

1. Land & Location

- Size Needed: Minimum 1 acre for mini plants; 3+ acres for large facilities.

- Cost Variations: Land in Southeast Asia costs 2k–8k/acre, while Middle East land ranges from 15k–25k/acre.

- Savings Tip: Choose land within 50km of raw materials (fly ash/cement) to cut transport costs by 15–20%.

2. Machinery & Automation

Machinery is 40–50% of your setup cost. We help you balance quality and budget:

| Machinery Type | Cost Range | Why It Matters |

| Ball Mill (Bigger Capacity) | 40k – 60k | Grinds raw materials for uniform mixing. |

| Tilt & De-moulding Machine | 50k – 75k | Speeds up block forming to boost output. |

| Air Compressor | 15k – 25k | Powers pneumatic tools for safety. |

We offer semi-automatic options for mini plants (lower cost) and fully automatic setups for large operations (faster ROI).

3. Labor & Compliance

- Labor Costs: 100k–150k/year for skilled operators (varies by region—we train local teams to reduce long-term costs).

- Permits & Licenses: 50k–75k to cover environmental approvals, building permits, and local business licenses (our team handles paperwork for you).

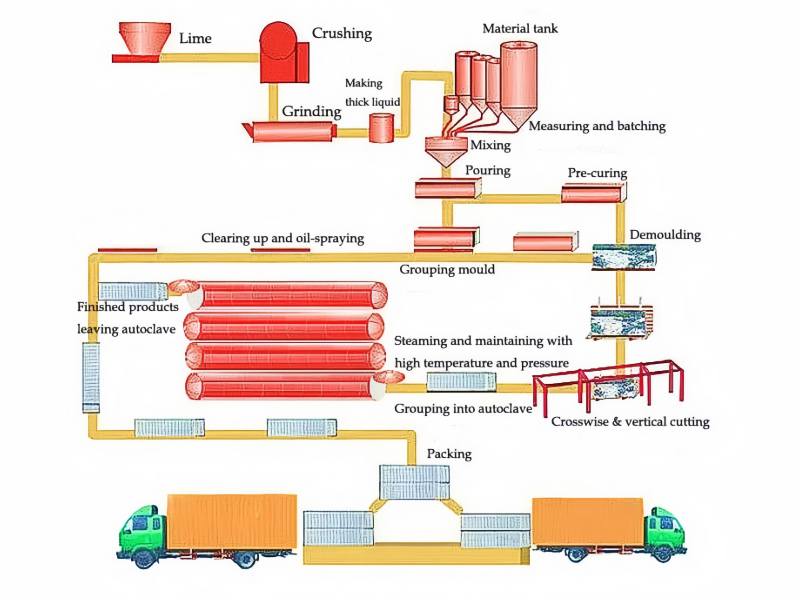

AAC Plant Proses Pembuatan

Raw material process → Batching and Mixing → Pouring → Static pre-curing → Cutting → Autoclaving Curing → Finished product Processing

1. Raw Material Processing: Sand is crushed and ground to the desired fineness. Cement, lime, and gypsum are stored in silos, and aluminum powder is mixed with water to form an aluminum slurry.

2. Batching and Mixing: The various raw materials are weighed according to precise proportions and then thoroughly mixed in a mixer to form a uniform slurry.

3. Pouring: The mixed slurry is poured into steel molds. The size and shape of the molds can be designed to meet the desired block specifications.

4. Static Pre-curing: The molds containing the slurry are transported to a pre-curing area where the slurry gradually hardens under suitable temperature and humidity conditions to achieve initial strength. This process typically takes several hours.

5. Cutting: After the slurry is pre-cured, it is cut into the desired size and shape using high-precision cutting equipment, steel wire or blades.

6. Autoclave Curing: Blocks are placed in an autoclave and cured for several hours at temperatures of 175-200°C and pressures of 10-15 bar, significantly enhancing the blocks’ strength and durability.

7. Finished Product Processing: After autoclave curing, the blocks are removed from the autoclave and transported to a storage area. After inspection and packaging, they are ready for shipment.

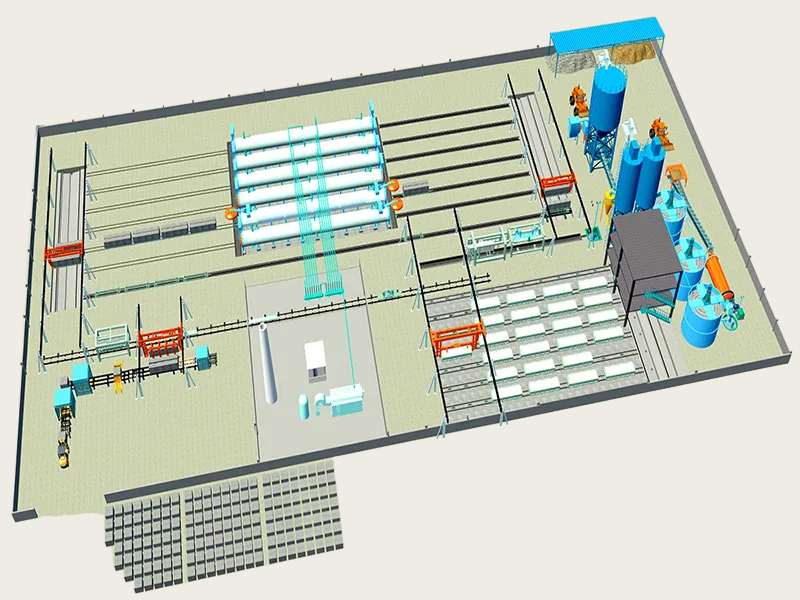

Our Case: 300,000 CBM/Year AAC Plant in USA

Mr. Carter, a US construction investor, aimed to meet LEED project demand. We built a 300,000m3/year plant with US-specific tweaks: used local fly ash ($22/ton) and complied with EPA rules.

- Total setup cost: $1.8M (land in Texas: $12k/acre, energy-saving autoclaves).

- Production cost: $45/CBM, selling price: $88/CBM.

- Annual profit (80% capacity): $1.2M,

- Pay-back: ~15 months.

“This plant cuts import reliance. We supply 8 green projects now. The team’s OSHA training was a big plus.”

Why Choose Us As Your Loji Pembuatan Blok AAC Partner?

- In-House Manufacturing: We make 100% of core equipment (no outsourcing) – our plants are 18% heavier (more durable) than competitors, but 7% cheaper.

- Global Experience: 260+ plants in 80 countries – we understand local regulations (e.g., EU CE, US EPA) and raw material characteristics (e.g., fly-ash in India, sand in Africa).

- End-to-End Support: From factory design to post-commissioning training – we don’t just sell equipment; we build profitable AAC businesses.

Get Your Custom Loji Pembuatan Blok AAC Quote Today

Share your requirements: target capacity (e.g., 100,000 m³/year) and land size.

We’ll deliver: A detailed P&ID (piping diagram), utility list (electricity/steam/water), and turn-key quote within 24 hours.

Related Autoclaved Aerated Concrete Plant

FAQ

Manufacturing (In Our 120,000 m² Factory): 45–90 days (depends on capacity)

Shipping: 20–40 days (varies by destination port)

On-Site Installation & Commissioning:

- 30,000–100,000 m³: 90 days

- 200,000–300,000 m³: 120 days

- 600,000 m³: 150 days

Timeline starts when we receive the down-payment – we provide a detailed Gantt chart to track progress.

Absolutely. As a professional AAC plant manufacturer, we provide end-to-end training:

- 2 weeks of factory training in China (your team learns equipment operation)

- 45 days of on-site training (our engineers teach formula adjustment, quality control, and maintenance)

- English-language manuals (formulas for B04/B05/B06 grades, lab testing procedures, troubleshooting guides)

- Life-long remote support (via Teams/Zoom – our engineers respond within 4 hours for urgent issues)

Yes. Our equipment holds CE, ISO 14001 (environmental management), ISO 9001 (quality management), GOST (for CIS countries), and SONCAP (for Nigeria) certifications. We also offer low-NOx burners (<30 mg/Nm³) and dust-collection systems to meet strict global regulations.

We partner with Sinosure (China’s export credit agency) and Standard Chartered Bank to offer 3–5 year equipment leases. Customers only need 15% initial cash – perfect for reducing upfront investment pressure.

Our core equipment (autoclaves, mixers, cutting machines) has a lifespan of 15–20 years – thanks to high-quality steel (Q345R for autoclaves) and precision manufacturing. We also offer a 5-year warranty on major components.