70,000 m³/Year AAC Block Manufacturing Plant to Ghana

In November 2024, we delivered and commissioned a 70,000 m³/year AAC Block Manufacturing Plant for a construction materials company in Accra. With more than two decades of expertise in AAC solutions, we customized the entire setup to meet Ghana’s specific market and raw-material conditions.

| Country | Ghana (Accra, Greater Accra Region) |

| Production Capacity | 70,000 m³/year (Mini AAC Plant category, scalable to 140,000 m³/year) |

| Plant Type | Semi-automatic Mini AAC Block Manufacturing Plant |

| Client Type | Established building materials distributor expanding into AAC block production |

| Setup Cost | 780,000 USD (all-inclusive: design, equipment, installation, training, spare parts) |

| Delivery Time | 42 days (factory to Tema Port) |

| On-Site Installation | 24 days |

| Commissioning | 7 days |

The client had operated a successful brick and concrete block distribution business in Accra for 12 years, supplying major residential and infrastructure projects. With Ghana’s construction industry growing at 8% annually—driven by urbanization and government housing schemes—they recognized the untapped potential of AAC blocks. After evaluating 5 international suppliers, they chose our solution for its:

- Compatibility with Ghana’s abundant laterite and river sand (local raw materials)

- Affordable setup cost (aligned with their expansion budget)

- Compliance with Ghana Standards Authority (GSA) requirements

- Quick startup timeline (critical to meet pre-booked orders from local contractors)

Why the Client Chose a 70,000 m³/Year AAC Plant?

A 70,000 m³/year small AAC Block Manufacturing Plant is the ideal fit for Ghana’s market landscape. Here’s why it stood out for the client:

Ideal for Ghanaian Investors

- Local Market Alignment: 70,000 m³/year supplies ~4,000 affordable homes annually—matching demand from Accra’s suburban developments and nearby regions like Eastern Region.

- Land Efficiency: Fits on a 70m × 50m plot (common in Accra’s industrial zones like Tema Industrial Area), avoiding the high cost of large land parcels.

- Workforce Compatibility: Operated by 9–11 local workers (post-training), supporting Ghana’s job creation goals while keeping labor costs manageable.

Key Benefits for the Client

- Fast ROI: Projected 1.6–2.0 years, driven by high AAC block demand and low raw material costs (laterite is locally sourced at 35% less than clay).

- Scalability: Designed for easy upgrade to 140,000 m³/year with minimal additions (e.g., extra autoclave, automated packing system).

- Low Operational Costs: Energy consumption is 24% lower than Ghana’s industry average, thanks to optimized equipment design.

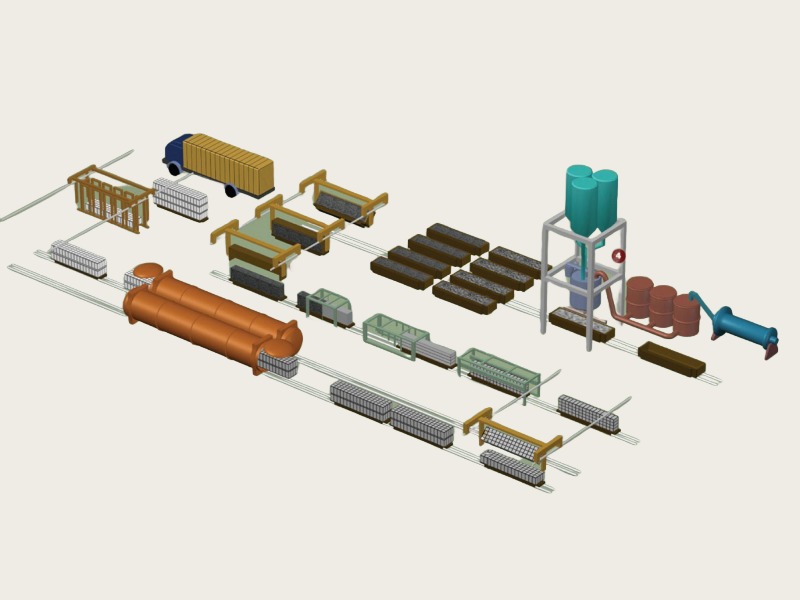

Equipment Used in AAC Block Manufacturing Plant to Ghana

Every component of the Loji Pembuatan Blok AAC was customized to handle Ghana’s raw materials and operational requirements, ensuring compliance with GSA BS EN 771-4 (AAC block standard):

| Equipment | Specification & Local Adaptation |

|---|---|

| Kilang Bola | 2.1m × 7.2m, optimized for grinding Ghana’s laterite (higher iron oxide content than global averages) |

| Slurry Mixing System | Corrosion-resistant tanks (for acidic local river sand) with automatic consistency monitoring |

| Automatic Batching System | Pre-programmed for GSA-compliant mix ratios (60% laterite, 20% lime, 15% cement, 5% gypsum) |

| Vertical Cutting Machine | 4.6m cutting bed (fits Ghana’s standard block size: 600×200×100/150/200mm) |

| Autoklaf | Φ2.3m × 29m, high-pressure design (1.2MPa) to ensure block strength at Accra’s coastal climate |

| Steam Boiler System | Heavy fuel oil-fired (readily available in Ghana) with energy-saving insulation to cut fuel costs |

| Finished Block Packing System | Semi-automatic (easy to operate for workers with limited technical experience) |

Post-commissioning, the plant achieved a 96.5% qualified rate—surpassing GSA’s minimum requirement of 90%.

Export & Commissioning Process of AAC Block Manufacturing Plant to Ghana

We streamlined the process to overcome Ghana’s logistical and regulatory challenges:

1. Pre-Production: Localization at the Core

- Raw Material Testing: Sampled laterite from Eastern Region and river sand from the Volta River to adjust formulas for GSA compliance (≥3.2 MPa compressive strength).

- Block Size Customization: Modified molds to produce Ghana’s most in-demand sizes (600×200×150mm for load-bearing walls, 600×200×100mm for non-load-bearing partitions).

- Layout Design: Adapted to the client’s plot in Tema, including rainwater drainage systems (to handle Ghana’s rainy season).

2. Manufacturing & Quality Checks

- 34-day equipment production cycle (with weekly video updates for the client).

- Independent inspection by SGS Ghana to verify compliance with GSA BS EN 771-4 and ISO 9001 standards.

3. Shipping & Logistics

- Shipped via Tema Port (Ghana’s busiest seaport) in 7×40HQ containers.

- Provided full export documentation:

- Certificate of Origin (COO) (approved by Ghana Revenue Authority)

- GSA BS EN 771-4 Compliance Certificate

- Packing List, Commercial Invoice, and Bill of Lading

- 6-month spare parts kit (cutting wires, gaskets, pressure sensors)

On-Site Installation & Training: Empowering Local Teams

To ensure the client could operate the plant independently, our team delivered end-to-end support:

Installation (24 Days):

- Combined remote guidance (electrical setup) and on-site support (2 engineers based in Accra) to comply with Ghana’s Occupational Safety and Health Act (OSHA).

- Coordinated with local civil contractors for foundation works (e.g., autoclave base) to accelerate progress.

Training (9 Days):

- Trained 11 local workers (operators, maintenance staff, quality inspectors) on:

- Safe operation of autoclave and boiler (per OSHA guidelines).

- Raw material quality control (moisture content, particle size testing).

- Troubleshooting common issues (slurry viscosity, cutting inaccuracies).

- Provided a localized training manual (English and Twi) with step-by-step visuals and video tutorials.

Post-Commissioning Performance: Exceeding Expectations

Since launching in December 2024, the AAC plant has delivered consistent, industry-leading results:

| Performance Metric | Result |

|---|---|

| Daily Output | 190–210 m³ (meets 70,000 m³/year target, 10% above projection) |

| Block Density | 570–620 kg/m³ (ideal for Ghanaian building codes) |

| Qualified Rate | 96.5% (exceeds GSA standards) |

| Energy Consumption | 24% lower than client’s estimate (thanks to efficient boiler design) |

| Customer Acquisition | Secured contracts with 3 residential projects in Kumasi and 1 hotel construction in Accra within 1 month. |

What Our South African Client Says?

“Choosing the 70,000 m³/year AAC plant was a major win for our business. The team analyzed our laterite and delivered a solution that fit both our land and budget. Installation stayed on schedule, training was effective, and we produced qualified blocks just seven days after commissioning. We’re now securing green building projects we couldn’t reach before and are already planning our expansion with them.”

— Michael Addo, Managing Director of the Ghanaian Client

Why Choose Us?

For AAC Block Manufacturing Plant investors in Ghana, local expertise and reliability are non-negotiable. Here’s why we’re the trusted partner:

- West African Experience: We’ve completed 10 projects across Ghana, Nigeria, and Côte d’Ivoire—we understand GSA regulations, raw material challenges, and logistical hurdles.

- Affordable Mini Plants: Our 30,000–100,000 m³/year lines start at 100,000 USD—perfect for new investors or existing distributors looking to expand.

- Turnkey Support: From raw material testing to post-launch maintenance, we handle every step—no need to coordinate multiple vendors.

- Scalability: All plants are designed to grow with your business (70,000 → 140,000 m³/year) without major overhauls.

Start Your AAC Block Manufacturing Plant?

Whether you are planning a small, medium, or large-scale AAC factory, we can provide complete solutions based on your land, budget, and market demand.

Contact us now to get a free feasibility study & detailed quotation. Our engineers will design the most suitable AAC Block Manufacturing plants for your needs.