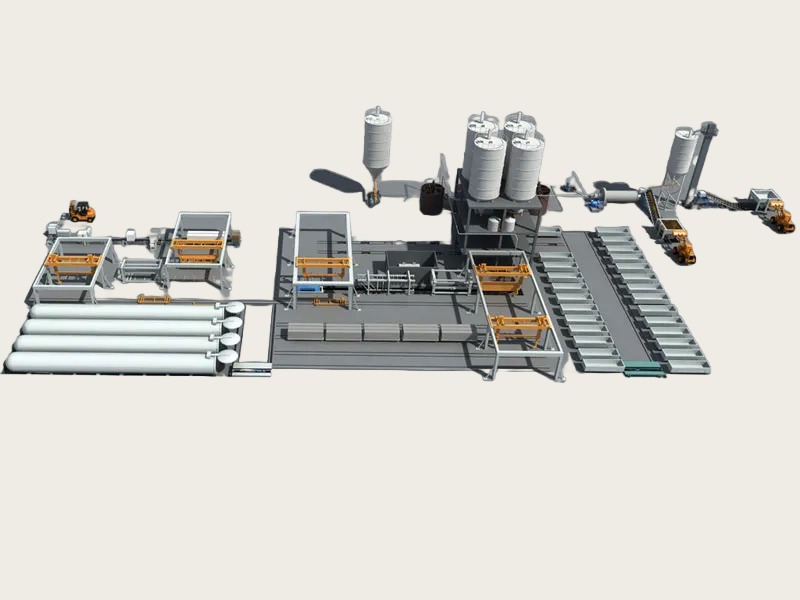

Mini AAC (autoclaved aerated concrete) plants typically refer to small-scale production lines with an annual output of 30,000–100,000 m³/Y.

For entrepreneurs starting an AAC block production business, a small AAC production line is a cost-effective and viable option.

Mini AAC Plant Cost ranges from $250,000 to $800,000.

What is the Cost of a Mini AAC Plant

The cost of a small AAC production line varies widely and depends on several factors. Generally speaking, the total investment for a small AAC production line with an annual capacity of 300,000-100,000 cubic meters ranges from $250,000 to $800,000.

- Barisan pengeluaran manual di India/Asia Tenggara: $250,000–400,000

- Barisan pengeluaran separa automatik di China: $350,000–550,000

- Fully automated production line for European and American CE standards: $600,000–800,000

Technical Parameters of Small AAC Production Line

Mini AAC Block Plant Capacity

| Mold Size (L×W×H) | Daily Output (m³) | Annual Output (m³) | Floor Area | Autoclave Specification |

| 2.0 × 1.2 × 0.6 m | 100 – 150 | 30,000 – 45,000 | 4,000 – 5,000 ㎡ | 2 units of Φ2.0 × 31.5 m |

| 4.2 × 1.2 × 0.6 m | 160 – 220 | 50,000 – 70,000 | 5,000 – 6,500 ㎡ | 2 units of Φ2.5 × 32 m and above |

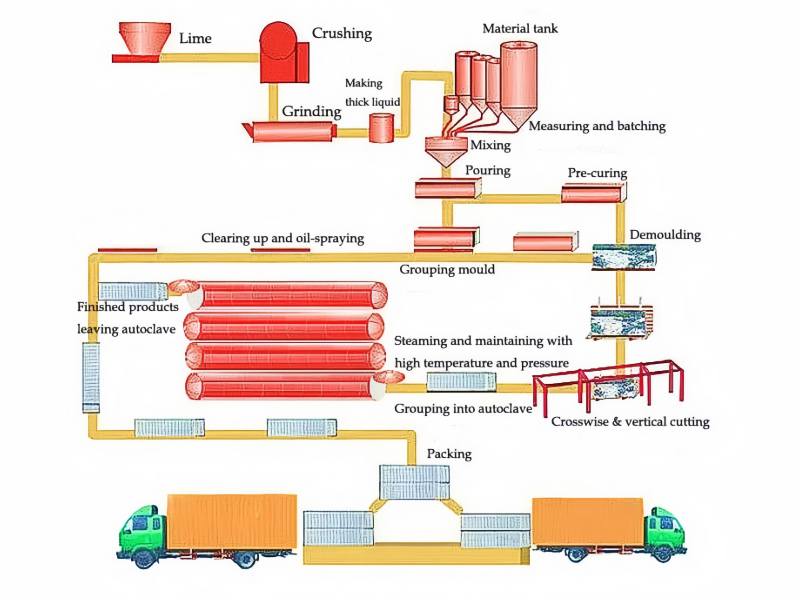

Mini AAC blocks Production Process

① Raw Material Grinding: Fly ash (or sand), lime, and cement are ground to a flour-like fineness to facilitate chemical reactions.

② Mixing: Pour the powder, water, and foaming agent (aluminum powder) into a large mixer, and bubbling begins within seconds.

③ In-Mold Foaming: The liquid is poured into the mold, where bubbles cause it to expand by two times its volume, forming a green body.

④ Curing: The green body is left at room temperature for 2–3 hours to solidify.

⑤ Turning and Cutting: Wire is used to cut the large green body into small pieces of precise size. Waste is automatically recycled.

⑥ Autoclaving: The small pieces are placed in an autoclave at 180–200°C and 1.0-1.3 MPa for 8-10 hours to achieve a high strength.

⑦ Demolding: After cooling, the lightweight, high-strength AAC blocks/boards emerge from the oven.

⑧ Packaging and palletizing: Robots or humans stack the finished products, affix barcodes, and directly load them for shipment.

Main Equipment Used in Mini AAC Block Production

- Jaw Crusher/Ball Mill: Grinds stone into powder.

- Pengadun: Used to thoroughly mix the raw materials.

- Molds and Side Plates: Molds are used to shape AAC blocks, and side plates are an important part of the mold assembly. For example, a small AAC production line may require 15 sets of molds and 162 side plates.

- Cutter: Precision cutters are used to cut pre-cured blocks into desired sizes.

- Autoklaf: A large pressure vessel used for steam curing aerated concrete blocks. A small AAC production line typically requires 3-4 autoclaves.

- Transfer and Conveying Equipment: Such as shuttles and cranes, used to move molds, blocks, and trolleys throughout the production process.

Jaw Crusher

Pengadun

Molds and Side Plates:

Cutter

Autoklaf

Transfer and Conveying Equipment

Advantages of a Small AAC Block Plant

Low Investment: Initial investment is low, requiring only 1/6–1/8 the investment cost of a large plant.

Suitable for the Local Market: Due to their smaller production capacity, small AAC production lines can effectively serve the local construction market, reducing transportation costs for raw materials and finished products.

Flexible Site: Even an old warehouse of 4,000 square meters can be converted.

Easy Expansion: Production capacity can be doubled by adding equipment later.

Quick Payback: Case studies show equipment payments are recovered within 3–4 months.

How Much Does It Cost to Start A Mini AAC Block Plant

The cost of starting a small AAC block plant varies depending on the region, market raw material prices, and labor costs. Taking a small production line with an annual output of 30,000-50,000 cubic meters as an example, the following are the upper limits of costs in China:

1. Land and Infrastructure

A small AAC production line typically occupies 3,000-5,000 square meters; if a compact layout is adopted, 1,200 square meters (approximately 12,000 square feet) can also operate.

- Land: Purchase or lease, prices vary significantly by city—US$80-120/square meter/year in first-tier cities and US$10-30/square meter/year in second- and third-tier cities. •

- Factory: Light steel structure workshop is USD 200–400/m2, concrete frame is USD 400-700/m2; for a small line with an annual output of 30,000 m³, a workshop of 800–1,200 m2 is sufficient, and the general contractor for civil engineering can complete the roof with USD 50,000–150,000.

2. Equipment

- Basic (semi-automated): ball mill, batching station, pouring mixer, cutter, two 31.5 m autoclaves, 2 t/h boiler. Total price: $250,000–400,000.

- Upgrade (fully automated robotic palletizing, inline packaging): Add $80,000–150,000 to the basic price.

3. Raw Material Costs

- Fly ash: If the power plant is within 50 km, truck freight costs $6–10/ton.

- Cement and lime: Fluctuating with commodity prices, the average price in Southeast Asia in 2024 was $60–75/ton. A small 30,000 m³/year production line consumes 2,000 tons of cement and 900 tons of lime annually, with a 30-45 day raw material payment period. Working capital of $50,000-70,000 is required.

- Aluminum powder/paste: A key foaming material, costs $3,200–3,600/ton, with an annual consumption of 12–15 tons.

4. Labor Costs

- Semi-automatic: 15–20 people/two shifts (2 for batching, 3 for cutting, 4 for kettle area, 2 for forklifts, 1 for testing, 1 for machine repair, 3 for management).

- Fully automated: 10–12 people are sufficient.

Based on the Southeast Asian average wage of US$300–500/person/month, the annual labor cost is US$50,000–120,000.

5. Utility Costs

- Electricity: Installed capacity 400–800 kW, actual load 65%, annual electricity consumption 900,000–1.6 million kWh. Industrial electricity price $0.07–0.12/kWh, annual cost $60,000–200,000.

- Water: Producing 1 m³ of finished product requires 0.3-0.4 m³ of water, annual consumption 10,000–40,000 m³, water cost $3,000–12,000.

- Steam: Boiler natural gas consumption 70–90 m³/hour, annual consumption 250,000-400,000 m³, at $0.35/m³, cost approximately $90,000–140,000.

6. Permits and Compliance

Environmental impact assessment, safety assessment, production license, fire protection, and food-grade pressure vessel registration (autoclave), a full package costs $5,000-15,000.

7. Miscellaneous Costs

- Logistics: Raw materials arriving within a 20–30 km radius cost $20,000–50,000 in annual freight; finished goods sold within a 100 km radius cost $50,000–80,000 in freight.

- Maintenance: Annual equipment maintenance costs are approximately 2-4% of the equipment price; a spare parts inventory of $10,000–20,000 is sufficient to start.

- Unforeseen circumstances: Reserve 5% of the total investment as a reserve fund.

Factors Affecting the Cost of a Mini AAC Line

Automation Level: Fully automated units and lines are 20–30% more expensive than semi-automated lines, but offer 40% less labor.

Raw Material System: Fly ash lines are 5–10% cheaper than sand lines.

Autoclave Length: 31 m vs. 38 m, a difference of $80,000–100,000.

Electrical Standards: CE/UL certified components carry a 15–25% price premium.

Equipment Manufacturer and Quality: Well-known manufacturers known for high-quality equipment may charge a premium. However, investing in reliable equipment can reduce maintenance costs in the long run.

Site Selection: Land costs and local construction costs vary by location. Choosing a location with convenient transportation and proximity to raw material sources and markets can also affect transportation costs.

Production Capacity: Small AAC lines with larger production capacities (approaching 500 cubic meters per day) may require more equipment and infrastructure, increasing costs.

Ways to Reduce Setup Costs for Small AAC Manufacturing Lines

- Choosing Semi-Automated or Manual Equipment: If your budget is limited, choosing semi-automated or manual equipment over fully automated equipment can significantly reduce your initial investment.

- Sourcing Raw Materials Locally: Purchasing raw materials from local suppliers can reduce transportation costs.

- Using containerized, prefabricated steel structures is 30% cheaper than traditional concrete plants.

- Negotiating with Equipment Manufacturers: Try to negotiate better pricing, payment terms, or package deals with equipment manufacturers.

- Efficient Factory Layout: Design an efficient factory layout to minimize the need for excessive infrastructure and equipment.

Mini AAC Plant Cost VS. Large AAC Plant Cost

| Indicator | Mini Line (30,000 m³/year) | Large Line (300,000 m³/year) | Remarks |

| Single Line Investment | 0.475 M USD | 3.0–3.5 M USD | Approximately 1/6–1/7 of the large line |

| Payback Period | 3–4 months | 12–18 months | Small plants have faster cash flow |

| Energy Consumption per Unit | 34 kWh/m³ | 29 kWh/m³ | Gap < 15%, which is acceptable |

| Expansion Difficulty | Modular +50% capacity | Requires new factory construction and approval | Can be upgraded at any time in the later stage |

| Management Difficulty | Operable with 15 people | Team of 80+ people | Labor costs and complexity of small plants are significantly reduced |