150,000 m³/Year AAC Block Plant for Italy

| Country | Italy |

| Plant Type | Medium AAC Block Plant |

| Capacity | 150,000 CBM/year |

| Setup Cost Range | USD 1.2M – 2.3M |

| Application | Commercial and residential construction |

| Automation Level | Fully Automatic |

| Project Duration | 6 Months (Design → Installation → Commissioning) |

| Standards | CE-certified equipment, EU-compliant control system |

AAC Products Manufactured in AAC Block Plant for Italy

The plant produces a full range of AAC construction materials:

- AAC wall blocks (600×200×100–300mm)

- Partition blocks

- Jumbo blocks

- U-shaped lintel blocks

- Sound-insulation blocks

- Reinforced AAC panels (optional line planned for Phase 2)

Why Italy Is Choosing AAC Block Production Lines?

Italy’s construction industry is rapidly shifting toward sustainable, high-precision building materials. Several market factors make AAC production especially attractive in the region:

1. EU Energy Efficiency Requirements

AAC blocks help Italian builders comply with near-zero energy building standards due to natural insulation and low thermal conductivity.

2. High Labor Cost & Preference for Automation

Fully automatic AAC cutting and packing reduces manpower requirements—important for Italy’s high-cost labor environment.

3. Fast-Growing Demand for Lightweight Wall Solutions

Earthquake-prone regions in Italy prefer lightweight AAC blocks because of improved seismic performance compared to clay bricks.

4. Increasing Shortages of Local AAC Suppliers

Many regions rely on imported AAC, leading to higher transportation costs.

A local AAC plant reduces logistics expenses and increases regional competitiveness.

Equipment Configuration of AAC Block Plant for Italy

To meet European quality expectations, we supplied a high-precision and energy-efficient equipment line customized for Italy’s local environmental standards.

Main Equipment List

- Automatic batching & pouring system

- High-efficiency slurry mixing system

- Precision cutting machine (horizontal + vertical cutting)

- Tilting table and side plate return system

- Autoclaves (CE-certified, European safety standards)

- Steam curing system

- Automatic block separation system

- Palletizing & packing line

- Dust collection and waste recycling unit

The production line emphasizes:

- High accuracy (cutting tolerance ≤ ±1.5 mm)

- Low energy consumption

- Reduced operator workload

- High stability for long-term continuous production

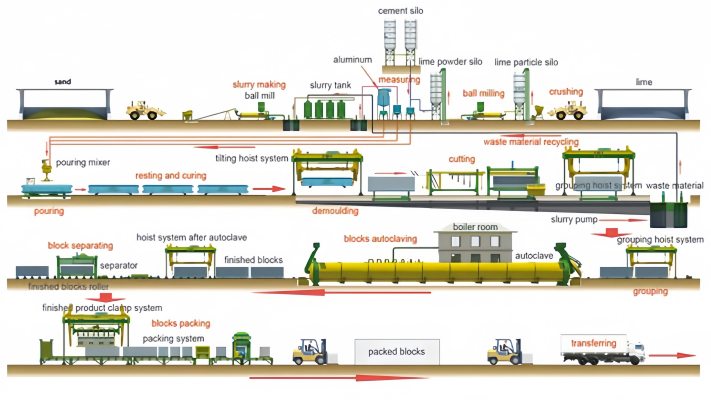

Complete Production Process

- Sand processing & grinding

- Slurry mixing

- Mold casting

- Pre-curing

- Tilting & demolding

- Horizontal & vertical precision cutting

- Grouping & autoclaving

- Steam curing cycle

- Final inspection

- Automated packaging & palletizing

Our engineers ensured stable production from day one.

Installation & Commissioning in Italy

Our engineering team provided full on-site support throughout the process.

Installation Steps

- Foundation drawing and plant layout design

- Equipment delivery & customs documentation

- Mechanical installation and assembly

- Electrical wiring & automation calibration

- Test runs with raw materials

- Training for Italian technical staff

- Official production handover

On-Site Training Included

- Equipment operation training

- Maintenance and safety training

- Quality control for raw materials

- Block strength and density testing methods

- Optimization for energy-saving operation

Production Performance After Commissioning

After several test runs, the plant achieved the following results:

Production Output

- Daily Output: 450–520 m³/day

- Annual Output: 150,000 m³/year

Product Quality

- Density: 550–650 kg/m³

- Compressive Strength: 4.0–5.0 MPa

- Thermal Conductivity: 0.12–0.14 W/mK

Cost Advantages

- 11–15% lower production cost than imported AAC

- 30% reduction in labor cost due to automation

- 18% energy savings (optimized autoclave cycle)

What Our Client Says?

“Your AAC plant has delivered exceptional performance from day one. The automation level is impressive, the cutting accuracy is excellent, and the entire line runs with remarkable stability.”

Why Choose Us?

1. 20+ Years of AAC Manufacturing Experience

We are one of the earliest and most experienced AAC equipment manufacturers in China.

2. Exported to 80+ Countries

Including Europe, USA, UAE, Saudi Arabia, Indonesia, Vietnam, and Africa.

3. CE-Certified Equipment

Fully compliant with EU safety and technical standards.

4. Turnkey Solutions

From feasibility studies to installation and after-sales service.

5. Cost-Effective but High-Precision Machinery

Cutting tolerance and stability meet top-tier European requirements.

Frequently Asked Questions from Italy Customers

Yes. All electrical components and safety devices meet EU standards.

Yes. We tested local sand and cement samples and adjusted the formula for maximum strength and insulation.

3–4 months depending on the customer’s construction speed.

Yes — we provide online support, video guidance, spare parts delivery, and optional on-site engineers.

Start Your AAC Block Manufacturing Plant?

Contact us today for a customized AAC manufacturing plant design, cost analysis, and turnkey solution tailored to your market.