150,000 m³/Year AAC Block Line in Canada

In June 2024, our company successfully exported a fully automatic 150,000 m³/year AAC block production line zu Canada.

This project marks another milestone in our 20+ years of manufacturing AAC block plants and delivering turnkey solutions to more than 80 countries worldwide.

| Artikel | Einzelheiten |

|---|---|

| Country | Canada |

| Plant Type | Medium AAC Block Production Line |

| Annual Capacity | 150,000 CBM/year |

| Production Range | AAC blocks (75–300 mm), AAC panels |

| Automatisierungsgrad | Fully automatic cutting + automatic batching |

| Project Type | Turnkey solution: design → manufacturing → installation → commissioning |

The customer is a well-established Canadian construction material supplier located in Vancouver.

Key background details:

- 20+ years in supplying building materials across British Columbia.

- Planning to expand its product line with AAC blocks due to Canada’s growing interest in green, thermal-insulated materials.

- Requirements included:

- A stable medium-capacity AAC production line

- High automation to reduce labor cost

- Equipment suitable for Canadian cold climates

- Custom block sizes to fit local building codes

- Training for operators with no AAC experience

During early discussions (January–February 2024), the customer emphasized that they needed European-level precision but at a more competitive investment cost, which is why they finally chose our solution.

Our Recommended Solution for AAC Block Line in Canada

After analyzing the customer’s land size, electricity tariff, expected demand, and financial plan, we recommended a 150,000 CBM/year AAC block plant, which fits the “Medium AAC Plant” category:

Why This Capacity Is Ideal for Canada

- Matches regional demand in Western Canada

- Avoids over-production

- Reduces initial investment risk

- Provides enough output to supply local distributors

- Production line footprint fits the customer’s 18,000 m² land

Main Design Highlights

- Full-automatic batching and pouring system

- Wire-cutting system for precise dimension control

- High-pressure autoclave designed for Canadian safety codes

- Customized layout optimized for cold-weather production

We also customized:

- Block sizes: 8×8×24 inch, 6×8×24 inch, 10×8×24 inch

- Density grades: AAC AAC400/500/600

- Frost-resistant additives for winter production

Key Advantages of AAC Block Line in Canada

✓ High Cutting Precision

Our advanced automatic cutting system ensures:

- Smooth block surfaces

- Less breakage rate

- Accurate dimensions (tolerance ±1.5 mm)

This is essential for the Canadian market, where precise modular construction is important.

✓ Fully Automated Operation

Automation reduces Canadian labor costs and improves consistency:

- Auto batching

- Auto pouring

- Auto tilting

- Auto cutting

- Auto grouping

- Auto autoclave control

Labor requirement is reduced to only 8–10 workers per shift.

✓ Energy-Efficient and Environmentally Friendly

- Steam recycling system

- Low fuel consumption

- Dust-free operation

- Meets Canadian environmental regulations

✓ Durable and Built for Cold Climates

All pipes, valves, and autoclave systems are designed for:

- Low-temperature operation

- High humidity resistance

- 25+ years of service life

✓ High Return on Investment

AAC block prices in Canada range from USD 80–120/m³, giving the customer a very strong profit margin.

Also Read: AAC-Anlage Hersteller

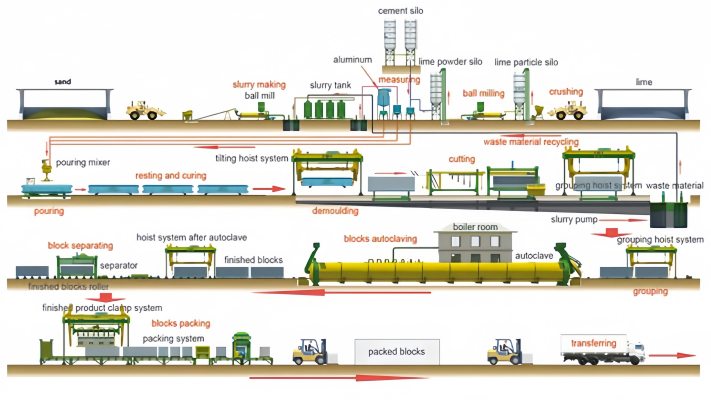

Major Equipment Shipped to Canada & Production Process

Main Equipment Included

- Raw material batching & mixing system

- Slurry & aluminum dosing system

- Moulds and casting machines

- Tilting crane

- Automatic cutting machine

- Side plate return system

- 3 × φ2.85m × 26m autoclaves

- Boiler system

- Packing system

- Electrical control system (PLC from Siemens)

Complete Production Process

- Raw material batching

- Slurry mixing

- Pouring into moulds

- Vorhärtung

- Tilting & demoulding

- Vertical and horizontal cutting

- Grouping & loading into autoclaves

- High-pressure steam curing (8–12 hours)

- Unloading & packing

- Storage & delivery

The entire system is fully automated and highly stable.

Service Workflow: From Inquiry to Plant Commissioning

Inquiry & Technical Discussion: We evaluated land layout, electricity supply, product plans, and ROI.

Customized Design: Provided 3D layout, equipment list, cost analysis, and shipping plan.

Production & Quality Inspection: he customer visited our factory for equipment testing.

Shipping to Vancouver Port: 41 containers shipped from Qingdao Port to Vancouver.

Installation & On-Site Training: Our engineers spent 42 days in Canada completing installation.

Test Production & Optimization: Output reached 98.5% of theoretical capacity within 2 weeks.

Plant Handover & Long-Term Support: Ongoing remote monitoring and spare parts supply.

Results Achieved After Commissioning

After trial operation, the plant achieved:

- Daily capacity: 480–520 m³

- Block breakage rate: < 3%

- Cutting precision: ±1–1.5 mm

- Energy consumption: 12% lower than customer’s expectation

- Labor cost reduction: 35% compared to manual production

What Our Client Says?

“Our 150,000 m³/year AAC line has been performing exceptionally well since installation.

The cutting accuracy is excellent, the automation has reduced our labor cost significantly, and the equipment runs very smoothly even during winter.

We are extremely satisfied with the overall quality and performance.”

— General Manager, Vancouver Construction Materials Co., Canada

Warum uns wählen?

✔ 20+ years of AAC manufacturing experience

We are one of the earliest AAC equipment manufacturers.

✔ Exported to 80+ countries

Proven performance in Europe, USA, Canada, Middle East, Southeast Asia.

✔ True turnkey solutions

Design → equipment → installation → commissioning → training.

✔ High automation & stable operation

Ideal for high labor cost countries such as Canada.

✔ Customized for cold climate manufacturing

Special designs for British Columbia and northern regions.

✔ Competitive pricing

Our plant delivers European-quality equipment at more reasonable investment cost.

Start Your AAC Block Manufacturing Plant?

Whether you are planning a klein, medium, oder large-scale AAC factory, we can provide:

- Feasibility report

- Plant design

- Equipment configuration

- Cost analysis

- Turnkey delivery and installation

- Long-term technical support

Contact us to get a complete proposal for your AAC block plant project.