AAC Block Manufacturing Plant Exported to Belgium

Recently, our company successfully exported a 200,000 m³/year AAC Block Manufacturing Plant for Belgium, helping a local building materials group expand into high-performance wall systems while reducing production cost and improving market competitiveness.

Client Location: Belgium

Plant Capacity: 200,000 m³/year

Production Range: AAC blocks (different densities), AAC panels (optional), reinforced elements (optional upgrade)

Automatisierungsgrad: Vollautomatisch

Energy Source: Natural gas/steam boiler (adapted to Belgium environmental regulations)

Project Purpose: Expand local production and replace imported AAC blocks with local manufacturing

This production capacity fits the Belgian market well—large enough to supply several provinces, but flexible enough for future expansion to 300,000 m³/year.

Why a 200,000 m³/year AAC Block Manufacturing Plant Fits Belgium?

Unlike high-population regions in Asia, Belgium’s building market demands high quality, strict compliance, and efficient delivery, not extremely high output.

A 200,000 m³/year AAC plant provides:

- Enough supply for regional construction companies

- Stable cost efficiency with minimal waste

- Balanced energy consumption under EU environmental standards

- Flexibility for block sizes used in Belgium (incl. 100/150/200/240mm thickness)

- The ability to add AAC panel line later without major restructuring

This capacity is considered ideal for EU mid-scale AAC manufacturers.

Customer Background & Requirements

The Belgian customer is a multi-material building group that previously imported AAC blocks from neighboring EU countries. With rising logistics costs and inconsistent supply, they decided to invest in a local AAC block factory.

Customer Requirements

- A stable, EU-compliant production line

- High automation to reduce labor cost

- Energy-efficient equipment

- Advanced cutting system for clean and accurate block edges

- Durable autoclaves designed for long service life

- Ability to produce non-combustible, thermal-insulation AAC blocks meeting Belgian regulations

After comparing suppliers from several countries, the customer chose us due to our certification, export experience, and engineering capability.

Highlights of AAC Block Manufacturing Plant for Belgium

1. Advanced Automatic Batching & Mixing System

Ensures precise raw material proportions to maintain consistent quality, density, and strength—critical for Belgium’s strict construction standards.

2. High-Density, High-Precision Cutting Machine

Our wire-cutting technology enables:

- Smooth block surface

- Accurate dimensions

- Minimum waste

- Faster curing time

Ideal for thin-bed mortar construction widely used in Belgium.

3. Durable Autoclaves with EU Safety Standards

We supply pressure vessels designed according to international standards, with:

- High-pressure resistance

- Long working lifespan

- Automatic safety monitoring

4. Energy-Saving Steam System

Belgium has strict energy regulations; our design includes:

- Fuel-efficient boilers

- Smart steam distribution

- Heat recovery system (optional)

These reduce overall energy cost and CO₂ emissions.

5. Fully Automatic Packing Line

Ensures clean, uniform packing suitable for transportation and storage in distribution centers.

On-Site Installation & Technical Support in Belgium

We sent our senior engineers to Belgium for:

- Plant layout optimization

- Installation guidance

- Workers’ training

- Commissioning & trial production

- Trouble-shooting and quality testing

Within a short commissioning period, the plant achieved stable output with qualified product density and compressive strength.

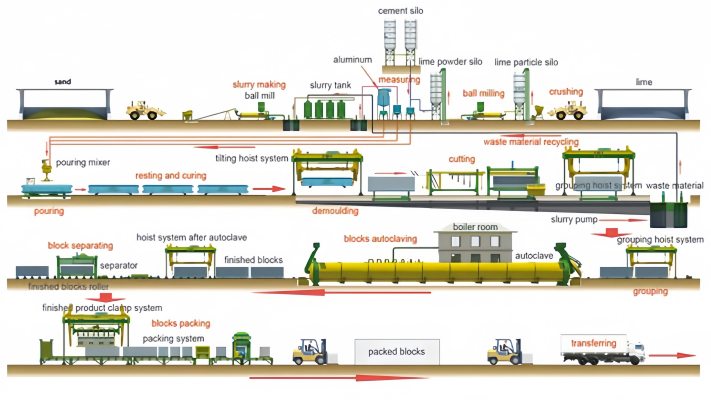

Complete Production Process

- Sand processing & grinding

- Slurry mixing

- Mold casting

- Vorhärtung

- Tilting & demolding

- Horizontal & vertical precision cutting

- Grouping & autoclaving

- Steam curing cycle

- Final inspection

- Automated packaging & palletizing

Our engineers ensured stable production from day one.

What Our Client Says?

“After installing the 200,000 m³/year AAC block production line, our overall efficiency improved immediately. Production costs dropped compared with imported blocks, and delivery time for local projects became much faster. The AAC blocks consistently meet Belgian quality standards, and the high automation greatly reduced our labor requirements. The line is also designed for future expansion, and we plan to add an AAC panel section next year. This project has helped us quickly establish ourselves as a competitive AAC supplier in Belgium, and we are very satisfied with the technical support throughout the installation and commissioning process.”

Warum uns wählen?

- 20+ years experience in AAC technology

- Exportiert in über 80 Länder

- Turnkey project support (design → installation → training)

- EU-standard autoclave and pressure vessels

- Stable equipment, low maintenance cost

- Strong mathematical formula system for Belgium-specific density classes

- Fast ROI for investors

- Affordable project cost with guaranteed quality

Looking to Build an AAC Block Manufacturing Plant?

Whether you need:

- A 50,000–600,000 m³/year AAC-Block-Herstellungsanlage

- Customized block densities

- Fully automatic or semi-automatic configurations

- Turnkey engineering support

- Cost estimation for a new AAC factory

We can provide a complete solution.

👉 Contact us today for a free feasibility report and quotation.

Our engineering team will design the best AAC block manufacturing solution for your market.