Turnkey Solutions for High-Quality Aerated Concrete Production

As a top AAC block plant supplier with 20+ years of experience, we offer factory-direct prices (no middleman fees) and have exported to 80+ countries worldwide. We provide complete AAC block production solutions, with our plants making lightweight, durable, eco-friendly AAC blocks—perfect for modern construction needing efficiency, sustainability, and cost savings. We’ve served 1800+ happy clients globally.

We provide fully automatic AAC block making plants and semi-automatic AAC block making plants. The production capacity ranges from 30,000 m³ to 600,000m³ per year.

- Production Capacity: 30,000 m³ to 600,000m³ per year (customizable).

- Automation Level: Semi-automatic (ideal for startups) to fully automatic (for high-volume production).

- Raw Material Flexibility: Adapt to fly ash, sand, or slag-based formulas (we test local materials for optimal results).

- End Products: Standard AAC blocks (500×200×100mm to 600×240×200mm), custom-shaped blocks, and lightweight panels.

Why AAC Blocks?

AAC blocks are revolutionizing the construction industry with unmatched benefits:

- Lightweight: 30-50% lighter than traditional concrete blocks, reducing structural load.

- Penebat Terma: Excellent heat resistance cuts energy costs for heating/cooling by 40%.

- Fire & Sound Resistance: Fire rating of 4+ hours and sound insulation up to 50 dB.

- Eco-Friendly: Made from industrial by-products (fly ash, slag) with low carbon emissions.

- Easy Installation: Precise dimensions reduce mortar use and construction time by 25%.

Loji Blok AAC With Various Capabilities for Your Needs

According to production capacity, Loji Blok AAC can be divided into small, medium and large scale.

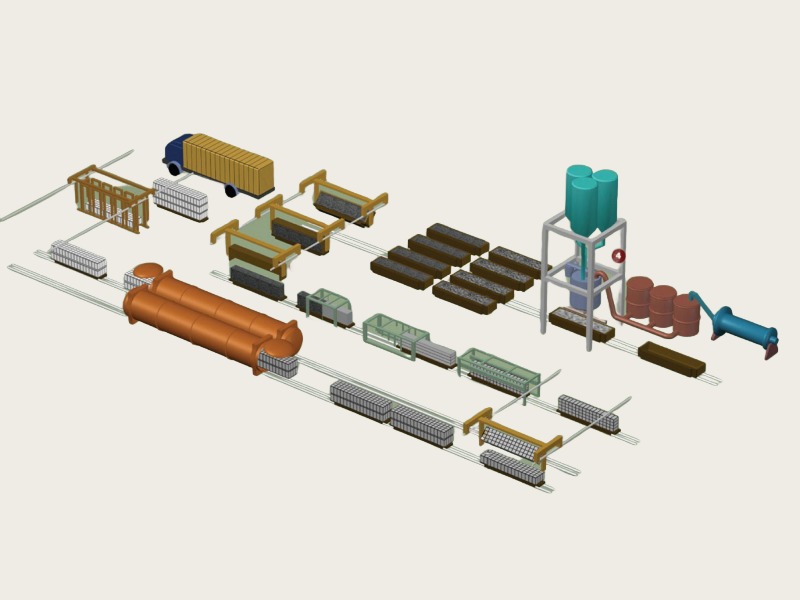

Mini/small Loji Blok AAC

Capacity: 30000-100000 m3/year

Autoklaf: 1-3 sets

Factory: about 4000-10000m2

Types: semi-automatic/ fully automatic

Features: low initial investment, high flexibility.

Suitable for: Start-ups or enterprises with limited investment and small market demand.

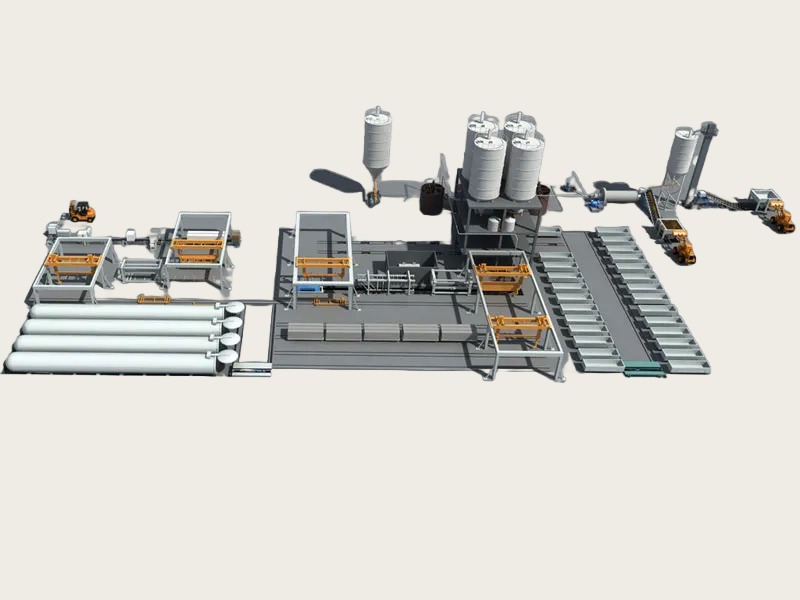

Skala sederhana Loji Blok AAC

Capacity: 100000-200000 m3/year

Autoklaf: 4-8 sets

Factory: about 10000-20000m2

Type: fully automatic

Features: stable production capacity, controllable costs, flexibility, large-scale production, etc.

Suitable for: Enterprises with a certain market share and stable demand.

What Makes Us the Top AAC Block Plant Supplier?

Cutting-Edge Technology & Equipment

Our plants integrate advanced technology to ensure consistent quality and efficiency:

- Precision Mixing System: Dual-shaft forced mixers guarantee uniform slurry (critical for block strength).

- CNC Cutting Machine: Achieves ±1mm accuracy, minimizing waste and ensuring perfect fit during construction.

- Intelligent Autoclaves: High-pressure (1.2MPa) and temperature (190℃) control for optimal curing, boosting block strength to ≥3.5MPa.

- Energy-Saving Design: Heat recovery systems and 90% water recycling reduce operational costs.

Strict Quality Controls

We adhere to global standards (ISO 9001, CE, ASTM) to deliver AAC blocks that meet international building codes:

- Raw Material Testing: Every batch of cement, lime, and additives is inspected for purity.

- In-Line Monitoring: Sensors track slurry density, curing time, and pressure to prevent defects.

- Final Inspection: Random sampling for compressive strength, density, and thermal conductivity tests.

Turnkey Solutions & Support

We handle every step from planning to production, so you can focus on growing your business:

- Pre-Sales: Free feasibility studies, factory layout design, and cost analysis (ROI projections included).

- Installation & Training: Our engineers install equipment on-site and train your team (3-7 days to full operation).

- After-Sales: 24/7 technical support, 72-hour on-site response, and a 10-year warranty on core components.

Global Reach & Local Expertise

With 1800+ clients in 80+ countries (Europe, Africa, Asia, Americas), we understand regional needs:

- Local Adaptations: Modify plants for climate (e.g., corrosion-resistant parts for humid regions) and raw materials.

- Regulatory Compliance: Ensure your AAC blocks meet local standards

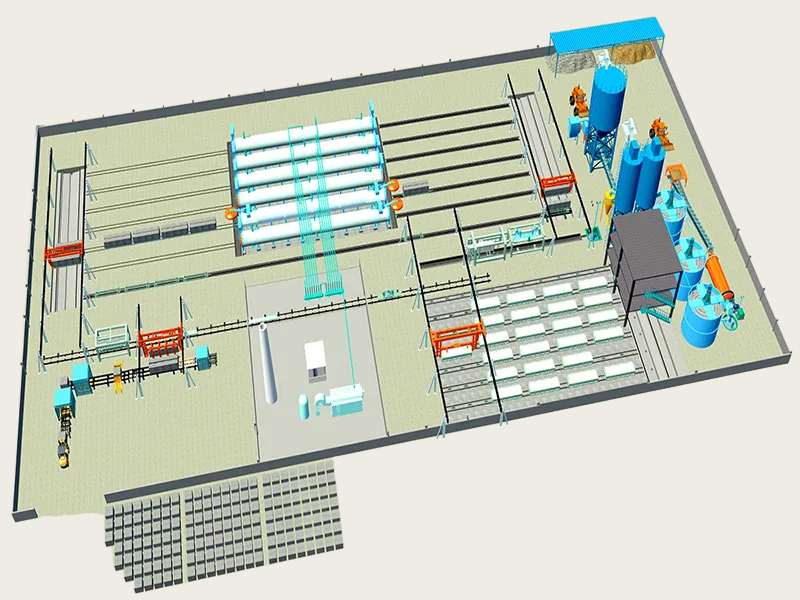

How AAC is Produced Step By Step in Our Plant?

Our Loji Blok AAC follows a scientific, efficient process to ensure consistent product quality:

- Raw Material Preparation: Crushing (lime, cement), grinding (fly ash/slag), and storage—with automatic feeding systems to control ingredient ratios.

- Mixing & Pouring: The mixing system blends raw materials with water and aluminum powder (foaming agent) into a slurry, which is poured into molds.

- Primary Curing: The slurry is cured at 40–50℃ for 2–3 hours to form a solidified block (initial setting).

- Cutting: CNC cutting machine trims the block into standard-sized AAC blocks/panels or customized shapes.

- Autoclaving: The cut blocks are placed in autoclaves for 8–12 hours of high-temperature, high-pressure curing—enhancing strength and thermal insulation.

- Cooling & Stacking: Autoclaved products are cooled to room temperature, then automatically stacked by a robotic arm for storage or delivery.

- Quality Inspection: Each batch of AAC products undergoes strength testing, density testing, and thermal conductivity testing to ensure compliance with standards.

Advantages of Our Automatic AAC Block Plant

- High Efficiency: Fully automatic plants achieve a production cycle of 12–16 hours (from raw material to finished product), with a 30% higher output than semi-automatic lines.

- Easy Operation: Equipped with a PLC control system and touchscreen interface—operators can monitor production data (temperature, pressure, output) and adjust parameters with one click.

- Stable Product Quality: Consistent mixing, curing, and cutting ensure AAC products meet global standards (compressive strength ≥ 3.5 MPa, thermal conductivity ≤ 0.12 W/(m·K)).

- Eco-Friendly: Uses industrial by-products (fly ash, slag) as raw materials, reduces carbon emissions by 40% compared to traditional concrete production, and recycles 90% of water.

- Wide Adaptability: Can produce AAC blocks (500×200×100 mm to 600×240×200 mm), AAC panels (2440×610×100 mm), and customized components (lintels, columns) to meet diverse construction needs.

- Low Maintenance: Equipment is made of wear-resistant materials, with modular design for easy part replacement—reducing downtime to ≤ 2 days/year.

Application of Our AAC Block Plant

Our AAC plants are widely used in the construction industry, catering to:

- Residential Construction: Production of lightweight AAC blocks for interior/exterior walls, reducing building load by 30% and improving sound insulation.

- Commercial & Industrial Construction: Manufacturing fire-resistant AAC panels (fire rating ≥ 4 hours) for shopping malls, factories, and warehouses.

- Infrastructure Projects: Supply of AAC lintels and prefabricated components for roads, bridges, and affordable housing projects.

- Renovation & Retrofitting: Small-scale AAC Block Plants for producing thin AAC panels to upgrade old buildings’ thermal insulation.

Honors & Certifications

We adhere to strict quality and safety standards, holding international certifications to ensure our AAC Block Plants meet global requirements:

- Quality Management: ISO 9001 Certification

- Environmental Management: ISO 14001 Certification

- Occupational Health & Safety: ISO 45001 Certification

- Product Compliance: CE Certification (for European markets), ASTM Certification (for North American markets), GB Certification (for Chinese markets)

- Industry Honors: National High-Tech Enterprise, Top 10 Green Building Equipment Supplier, Outstanding Export Enterprise

Top 5 AAC Block Plants Suppliers in China

There are many brand AAC Block Making Plant Manufacturers in China. They have not only gained a lot of users in China, but also exported to all over the word, wining a good reputation. The following are the top ten AAC Block Making Plant Manufacturers in China.

1. Anhui KEDA Industrial Co., Ltd.

Main Equipment: Complete AAC lines with an annual output of 200,000–800,000 m³.

Advantages: Only company in Asia to combine German AAC technology with localized Chinese manufacturing. The complete line energy consumption is ≤32 kWh/m³, 12% lower than the industry average. With over 170 complete lines worldwide.

Suitable for: Large groups, well-capitalized listed companies.

Advantages: With extensive experience in complete turnkey lines, can assist with applications for export credit and sovereign-guaranteed financing. The average project size is ≥500,000 m³.

2. Jiangsu Teeyer Intelligent Equipment Corp.

Main equipment: Teeyer-ACSR® longitudinal six-sided cutting units, Teeyer-AutoPack® automatic packaging lines, and waste heat recovery systems.

Advantages: The first manufacturer in China to achieve domestic production of AAC equipment (since 1997). With national-level CNAS-certified laboratory, and can verify raw material-level formulas for our customers. The full-line delivery cycle is ≤ 6 months, 30% faster than European suppliers.

Suitable for: Medium- to large-sized, established enterprises with a strong need to automate existing lines or those who prefer a phased investment approach.

3. Guangxi Hongfa Group

Main Equipment: Dual-purpose AAC/ALC production lines with an annual output of 100,000–600,000 m³, HF-Cut® high-precision cutting machines, and HF-Steam® energy-saving autoclaves.

Advantages: Equipment is CE, ISO 9001, and Russian GOST certified. 4S parts centers are located in Vietnam, Indonesia, and India, providing 72-hour delivery of overseas spare parts.

Suitable for: Growing companies planning to expand from medium to large within 5–10 years, and export-oriented enterprises in ASEAN/Middle East.

4. Beijing REIT Equipment Technology Co.

Main equipment: RT-AAC Mini series (50,000–150,000 m³ modular production lines), RT-Batch® cloud batching system, and RT-Edge® scrap recycling system.

Advantages: Focusing on the small and medium-sized market, the entire production line requires only 9,000 m² of floor space. Its containerized modular design allows for on-site assembly overseas within 45 days. It offers a light-asset lease-to-own model to alleviate cash flow pressure.

Suitable for: Startups, small, local private building materials manufacturers, and investors with limited funds who want to quickly enter the AAC market.

5. Aircrete China Co. Ltd.

Main Equipment: Aircrete-4.0® fully automatic panel production line, Aircrete-Cure® steam curing control system, Aircrete-WMS® intelligent warehousing.

Advantages: Exclusively licensed from Aircrete of the Netherlands, the globally patented “Stationary, Formless, and Gas-Enhancing” technology.

Suitable for: High-end panel manufacturers, prefabricated interior/steel structure enclosure companies seeking ≤1 mm diagonal accuracy.

Top 5 AAC Block Plant Suppliers All Over the World

1. HESS Group (Germany)

With over 70 years of experience, we have built over 100 complete AAC plants worldwide.

The superSMART series is renowned for its high-speed horizontal cutting and fully automated steam curing, with a single machine boasting a daily production capacity exceeding 2,000 m³.

With technical centers in Europe, North America, and Asia, HESS Group provides comprehensive EPC services, from process design to operations and maintenance training.

2. Masa Group (Germany)

With over 110 years of experience in concrete products, Masa offers complete AAC slab and block production lines with annual capacity ranging from 300,000 to 600,000 m³.

Its intelligent MES system supports remote diagnostics and predictive maintenance.

Masa Group has spare parts centers in Germany, the United States, and China, with a global response time of less than 24 hours.

3. Anhui KEDA Industrial Co. (China)

China’s largest complete AAC production line supplier, with over 50 production lines in operation overseas, covering India, the Middle East, Southeast Asia, and Eastern Europe.

Our independently developed zero waste cutting system and energy-saving steam curing kiln help customers reduce costs by an average of 8-12%.

4. Wehrhahn GmbH (Germany)

With over 100 years of experience in AAC technology, renowned for its highly customized capabilities.

The AKG Çorlu project in Turkey boasts a daily production capacity of 2,074 m³, setting a new global record for the largest single unit.

The superSMART 2000 series supports seamless expansion to reinforced AAC panels, providing investors with room for future upgrades.

5. Aircrete Europe BV (Netherlands)

As the global pioneer in flat-bread cutting and horizontal steam curing, we have built over 100 AAC plants in 20 countries.

The modular Flat-Cake system reduces board scrap rates to less than 0.5%, making it highly sought after in the high-end board market.

The above five AAC Plant Supplier all have turnkey EPC capabilities and can provide differentiated solutions based on customers’ production capacity, budget and environmental requirements. They are the preferred partners for building or upgrading AAC plants around the world.

Ready to Start Your AAC Block Business?

Whether you’re a startup, SME, or investor, we have the right solution for you. From budget-friendly mini lines to high-automation turnkey projects, we will guide you from planning to profit.