Autoclaved Aerated Concrete (AAC) is a lightweight, porous prefabricated building material made from quartz sand/fly ash, cement, lime, and gypsum, with aluminum powder as a foaming agent.

It undergoes a process of batching, mixing, aeration, pre-curing, cutting, and autoclaving. Its density is 300-800 kg/m³, only 1/5 that of traditional concrete.

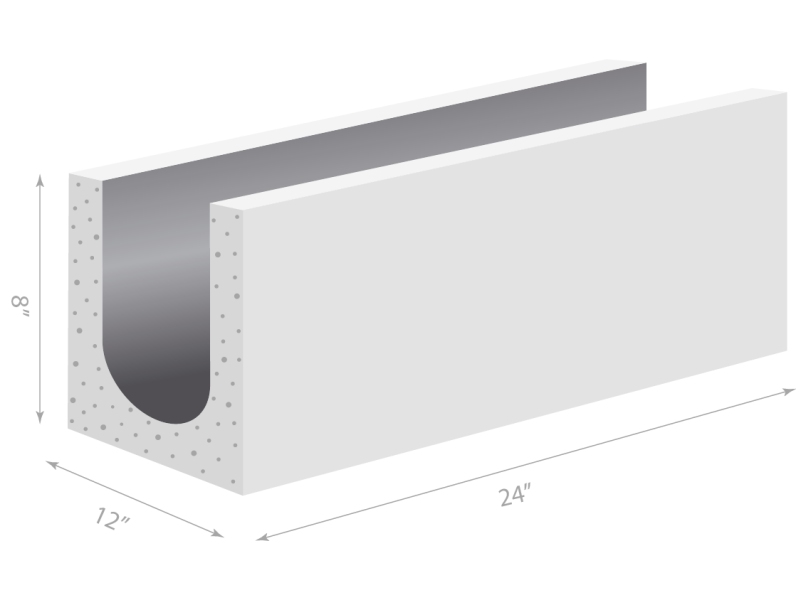

3 Types of AAC blocks

Standard AAC blocks

The most common type, used for walls, partitions, and load-bearing structures.

AAC panels

Large, thin panels ideal for floor and roof applications, offering quick installation.

AAC lintels and blocks with grooves

Designed for easy integration with other building elements, ensuring secure connections.

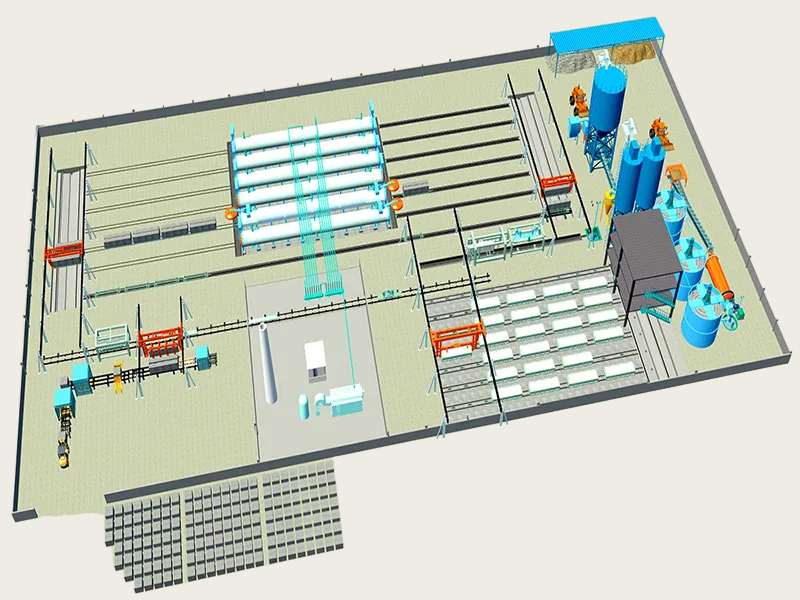

What is Autoclaved Aerated Concrete AAC plant?

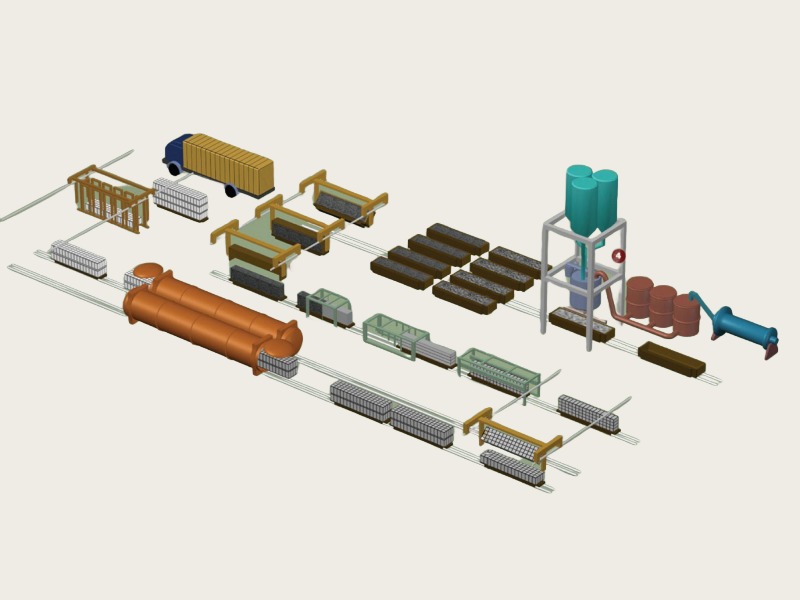

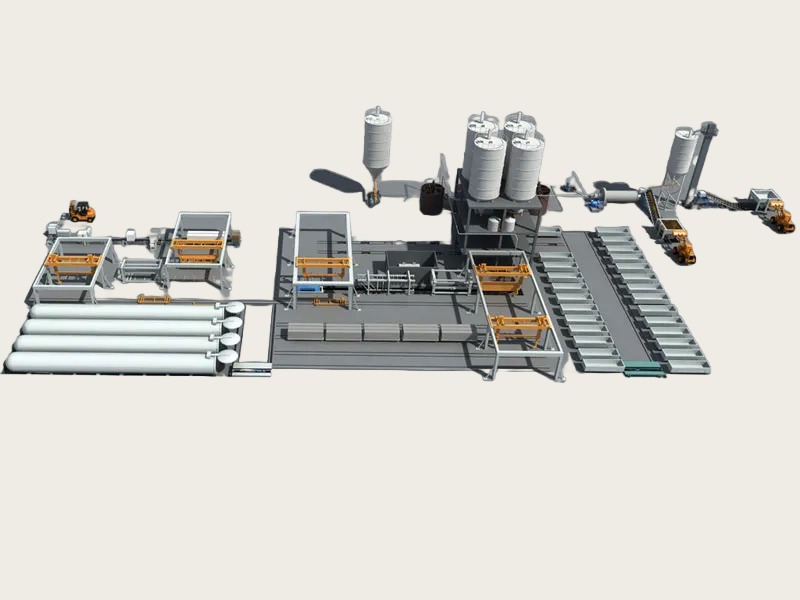

Autoclaved Aerated Concrete AAC Plant specialize in the production of aerated concrete blocks and slabs. These production lines and plant range in capacity from small-scale (30,000 to 100,000m3/year) to large-scale lines (over 500,000m3/year). Modern Autoclaved Aerated Concrete AAC Plant incorporate automated systems for precise mixing, casting, cutting, and autoclave handling, ensuring quality and efficient production.

Mini/small Autoclaved Aerated Concrete AAC Plant

Capacity: 30000-100000 m3/year

Autoklaf: 1-3 sets

Factory: about 4000-10000m2

Types: semi-automatic/ fully automatic

Features: low initial investment, high flexibility.

Suitable for: Start-ups or enterprises with limited investment and small market demand.

Medium- Scale Autoclaved Aerated Concrete AAC Plant

Capacity: 100000-200000 m3/year

Autoklaf: 4-8 sets

Factory: about 10000-20000m2

Type: fully automatic

Features: stable production capacity, controllable costs, and flexibility and large-scale production.

Suitable for: Enterprises with certain market share and stable demand.

Costs of Autoclaved Aerated Concrete AAC plant

| Scale | Capacity Range | Equipment & Installation Cost | Land & Infrastructure Cost | Total Investment Range | Estimated Payback Period |

|---|---|---|---|---|---|

| Kecil | 30,000–100,000 m³ (Small) | $400,000–$1,000,000 | $150,000–$300,000 | $600,000–$1,300,000 | 2.0–2.5 years |

| Medium | 100,000–200,000 m³ (Medium) | $1,000,000–$2,000,000 | $500,000–$800,000 | $1,500,000–$2,800,000 | 2.0–2.8 years |

| besar | 300,000–500,000 m³ (Large) | $2,000,000–$3,500,000 | $800,000–$1,500,000 | $2,800,000–$5,000,000 | 2.5–3.5 years |

The payback period is estimated based on a net profit margin of 25–30%. The actual period is subject to fluctuations in market prices, capacity utilization rate, and cost control efficiency.

How is Autoclaved Aerated Concrete Block Made?

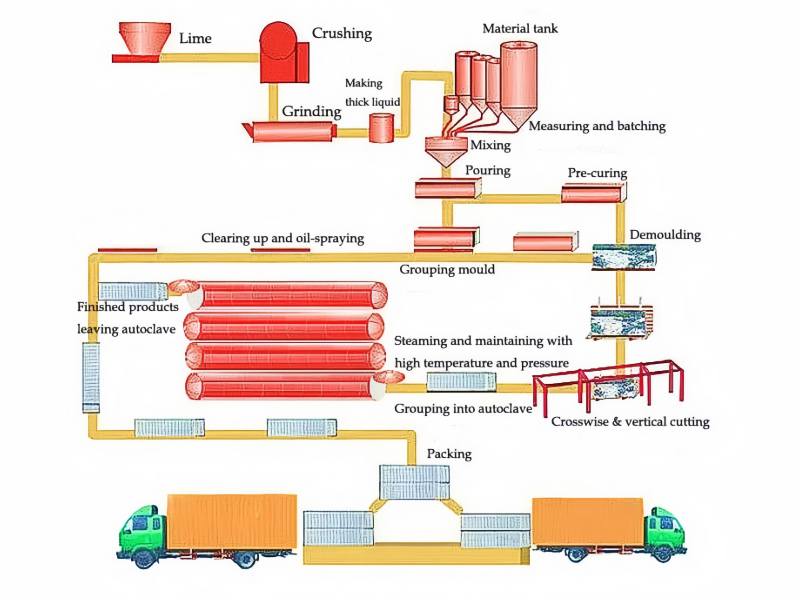

The production process of the Autoclaved Aerated Concrete AAC Plant is a carefully controlled sequence of steps:

Raw material preparation: Sand, cement, lime, and fly ash are crushed, sieved, and stored in silos.

Mixing: The materials are blended with water in precise proportions to form a slurry. Aluminum powder is added to initiate foaming.

Casting and rising: The slurry is poured into molds, where it expands as aluminum reacts with other components, forming air bubbles.

Pre-curing: The material sets in molds for several hours, gaining initial strength.

Cutting: After pre-curing, the blocks are cut into precise sizes using wire saws.

Autoclaving: The cut blocks are cured in an autoclave under high pressure (up to 12 bar) and temperature (around 180–200°C) for 8–12 hours, allowing the formation of strong calcium silicate hydrate bonds.

Packaging and storage: Finished blocks are inspected, packaged, and stored for distribution.

Raw Materials Used in Autoclaved Aerated Concrete Block Production

Sand: A primary aggregate, often sourced locally to reduce transportation costs.

Fly ash: A byproduct of coal-fired power plants, reused in AAC to minimize waste.

Cement and lime: Essential binders that react to form the material’s structure.

Aluminum powder: A small but critical component for creating the aerated structure.

Water: Used in mixing and curing, with many plants implementing water recycling systems.

Equipment Used in AAC block Autoclaved Aerated Concrete Block plant

1. Raw Material Handling Equipment

Crusher: Crushes raw materials such as sand and lime to the specified particle size. Jaw crushers are used for hard materials, and impact crushers are used for fine crushing.

Screener: Vibratory screening removes impurities and ensures uniform raw material particle size.

Storage Silo: Stores pre-treated raw materials and is equipped with a level meter and dust removal device to ensure continuous production and environmental protection.

Weighing Scale: Belt or spiral scales accurately measure raw material quantities to minimize formulation errors.

2. Mixing and Foaming Equipment

Forced Mixer: Mixes solid raw materials and water at high speed to form a uniform slurry, laying the foundation for foaming.

Aluminum Powder Mixing Tank: Mixes aluminum powder suspension at low speed to prevent sedimentation and ensure uniform dispersion.

Foaming System: Aluminum powder suspension is injected in proportion to react with the slurry to generate bubbles, which are then linked to the mixer for automated control.

3. Casting and Forming Equipment

Molds: Custom-made high-strength steel with a special surface treatment, adjustable in size to accommodate different product specifications.

Casting Machines: Precisely control the slurry injection volume, and some are equipped with automatic travel to prevent material shortages or overflow.

Curing Chamber: A constant temperature and humidity environment ensures slurry aeration and initial setting, resulting in a uniform porous structure.

4. Cutting Equipment

Turning Table: Hydraulically driven, smoothly rotates the mold and blank for demolding and cutting.

Wire Saw: Multiple sets of high-strength steel wires are used for high-speed cutting. The CNC system ensures millimeter-level accuracy. Large equipment can perform continuous cutting at multiple stations.

5. Autoclave Curing Equipment

Autoclaves: Large pressure vessels cure blanks at temperatures of 180–200°C and pressures of 10–12 bar, forming high-strength calcium silicate hydrates. Equipped with safety interlocks.

6. Auxiliary Equipment

Steam Boilers: Provide stable steam to operate the autoclave and curing chamber, offering a variety of heating options. Air compressor: Provides compressed air for pneumatic equipment, ensuring the proper operation of valves, clamps, and other devices.

Conveyor belt system: Transports materials throughout the entire process, using either belt or chain conveyor belts tailored to specific material needs for automated, continuous transport.

Sistem kawalan: PLC or DCS systems monitor and adjust production parameters in real time, recording data for management and traceability, and enabling timely resolution of any anomalies.

Applications of Autoclaved Aerated Concrete Block

AAC’s versatility makes it suitable for a wide range of construction applications:

Residential buildings: Walls, floors, and roofs in houses and apartments.

Commercial structures: Offices, malls, and hotels benefit from its insulation and fire resistance.

Industrial facilities: Used for partitions and external walls due to durability.

Infrastructure projects: Bridges, tunnels, and sound barriers leverage its lightweight properties.

Benefits of Using AAC Block

Lightweight: Reduces structural weight by 20-30%, reducing foundation costs.

Insulation and Energy Saving: Thermal conductivity of 0.10-0.16 W/(m·K) reduces heating and cooling energy consumption.

Fireproof: A1-grade non-combustible, 100 mm wall fire resistance for 4 hours.

Seismic Resistance: Low density, good integrity, and low seismic inertia.

Soundproof: 10 cm wall insulation of 41 dB, blocking sound transmission and improving indoor comfort.

Quick: Large panels can be installed at 8-10 m²/person/shift, reducing construction time by 40%.

Green: Solid waste utilization rate ≥ 60%, zero wastewater discharge.

Precision: CNC cutting, finished product tolerance ≤ ±1 mm, thin-layer masonry reduces mortar consumption by 70%.

Environmental: Uses industrial waste (fly ash), resulting in lower production energy consumption than traditional concrete.

What is Autoclaving?

Autoclaving is a critical curing process where AAC blocks are exposed to high-pressure steam in a sealed vessel (autoclave).

- This process triggers a chemical reaction between silica (from sand or fly ash) and calcium (from cement and lime), forming calcium silicate hydrates—strong, crystalline compounds that give AAC its strength.

- Ensures uniform curing, enhancing material consistency.

- Reduces drying time compared to air curing.

- Improves durability and resistance to environmental factors.

Top 5 Autoclaved Aerated Concrete Block Plant Manufacturers in China

There are many brand Autoclaved Aerated Concrete Block Plant manufacturers in China. They have not only gained a lot of users in China, but also exported to all over the word, wining a good reputation. The following are the top ten manufacturers in China.

1. Anhui KEDA Industrial Co., Ltd.

Main Equipment: Complete AAC lines with an annual output of 200,000–800,000 m³.

Advantages: Only company in Asia to combine German AAC technology with localized Chinese manufacturing. The complete line energy consumption is ≤32 kWh/m³, 12% lower than the industry average. With over 170 complete lines worldwide.

Suitable for: Large groups, well-capitalized listed companies.

Advantages: With extensive experience in complete turnkey lines, can assist with applications for export credit and sovereign-guaranteed financing. The average project size is ≥500,000 m³.

2. Jiangsu Teeyer Intelligent Equipment Corp.

Main equipment: Teeyer-ACSR® longitudinal six-sided cutting units, Teeyer-AutoPack® automatic packaging lines, and waste heat recovery systems.

Advantages: The first manufacturer in China to achieve domestic production of Autoclaved Aerated Concrete Block Plant (since 1997). With national-level CNAS-certified laboratory, and can verify raw material-level formulas for our customers. The full-line delivery cycle is ≤ 6 months, 30% faster than European suppliers.

Suitable for: Medium- to large-sized, established enterprises with a strong need to automate existing lines or those who prefer a phased investment approach.

3. Guangxi Hongfa Group

Main Equipment: Dual-purpose AAC/ALC production lines with an annual output of 100,000–600,000 m³, HF-Cut® high-precision cutting machines, and HF-Steam® energy-saving autoclaves.

Advantages: Equipment is CE, ISO 9001, and Russian GOST certified. 4S parts centers are located in Vietnam, Indonesia, and India, providing 72-hour delivery of overseas spare parts.

Suitable for: Growing companies planning to expand from medium to large within 5–10 years, and export-oriented enterprises in ASEAN/ the Middle East.

4. Beijing REIT Equipment Technology Co.

Main equipment: RT-AAC Mini series (50,000–150,000 m³ modular production lines), RT-Batch® cloud batching system, and RT-Edge® scrap recycling system.

Advantages: Focusing on the small and medium-sized market, the entire production line requires only 9,000 m² of floor space. Its containerized modular design allows for on-site assembly overseas within 45 days. It offers a light-asset lease-to-own model to alleviate cash flow pressure.

Suitable for: Startups, small, local private building materials manufacturers, and investors with limited funds who want to quickly enter the AAC market.

5. Aircrete China Co. Ltd.

Main Equipment: Aircrete-4.0® fully automatic panel production line, Aircrete-Cure® steam curing control system, Aircrete-WMS® intelligent warehousing.

Advantages: Exclusively licensed from Aircrete of the Netherlands, the globally patented “Stationary, Formless, and Gas-Enhancing” technology.

Suitable for: High-end panel manufacturers, prefabricated interior/steel structure enclosure companies seeking ≤1 mm diagonal accuracy.

The History of Autoclaved Aerated Concrete Block

AAC was invented in the 1920s by Swedish architect and inventor Johan Axel Eriksson. The first commercial production began in Sweden in 1929, and by the mid-20th century, AAC had gained popularity across Europe. In the latter half of the century, its use spread to Asia, North America, and other regions, driven by growing demand for sustainable building materials. Today, AAC is a globally recognized construction material, with continuous advancements in production technology.

Autoclaved Aerated Concrete Market Trends

Sustainable construction: Increasing focus on eco-friendly materials boosts demand for AAC, which reduces carbon footprints.

Urbanization: Rapid urban growth in emerging economies fuels the need for efficient, cost-effective building solutions.

Energy efficiency regulations: Stricter building codes mandating better insulation drive adoption of AAC.

Technological advancements: Innovations in AAC block plant automation and material science improve product quality and production efficiency.

Global expansion: Growing awareness of AAC’s benefits leads to increased adoption in new regions, expanding market reach.