180,000 m³/Year AAC Block Plant in Mexico

In May 2024, we successfully exported a fully automatic 180,000 m³/year AAC Block Plant in Mexico.

| Country | Mexico |

| Plant Category | Planta de CCA média |

| Annual Capacity | 180,000 m³/year |

| Production Types | AAC blocks (75–300 mm), optional AAC panels |

| Nível de automatização | Fully automatic batching + auto cutting + auto autoclave |

| Project Type | Turnkey plant (design → manufacturing → installation → commissioning) |

The client is a construction materials company based in Querétaro with distribution channels in central Mexico. Before adopting AAC technology, they mainly supplied concrete blocks and mortar. With Mexico’s rising demand for lightweight, seismic-resistant, and thermally insulated building materials, the company aimed to expand into AAC manufacturing.

Customer’s Key Requirements

- Medium-capacity AAC block plant suitable for regional supply

- Automated production to reduce labor costs

- High cutting precision to meet Mexico City’s seismic construction standards

- Ability to produce popular sizes such as 15×20×60 cm e 12×20×60 cm

- Energy-efficient equipment suited for warm climates

- Complete installation, training, and commissioning support

After comprehensive technical discussions, site planning analyses, and cost evaluations, the customer decided to purchase our 180,000 m³/year fully automatic AAC production line.

Recommended Solution — 180,000 m³/year Medium AAC Plant

We recommended a Planta de CCA média (100,000–200,000 m³/year) because it fits perfectly with Mexico’s current AAC market size.

Why Medium AAC Plant Is Ideal for Mexico

- Suitable for fast-growing regional markets like Querétaro, Guanajuato, Puebla

- Balanced investment cost: USD 1.2–2.3 million

- Flexible production volume

- Meets the needs of developers and distributors

- Provides strong ROI due to Mexico’s increasing AAC adoption

Plant Design Customization

We tailored the plant for the Mexican market with:

① Customized block sizes:

- 10×20×60 cm

- 12×20×60 cm

- 15×20×60 cm

- 20×20×60 cm

② Density grades:

- AAC 500

- AAC 600

③ Climate-adapted design:

- Anti-corrosion treatments for hot & humid areas

- Energy-saving steam system

- Dust-proof batching room

④ Optimized layout for land usage:

Land area provided: 22,000 m² → Our team provided a customized 3-line layout for future expansion.

Key Advantages of AAC Block Plant in Mexico

✓ High Cutting Accuracy for Better Wall Quality

Our cutting system maintains ±1–1.5 mm precision, ensuring:

- Smooth wall finish

- Lower mortar usage

- Faster installation speed

This is a major advantage in Mexico’s construction sector where speed and cost efficiency are critical.

✓ Fully Automatic Operation — Lower Labor Cost

The fully automated system includes:

- Auto batching

- Auto pouring

- Auto tilting

- Auto cutting

- Auto autoclave loading

- Auto block packing

This reduces labor needs to only 10–12 workers per shift, significantly lowering operating costs.

✓ Energy Saving and Low Steam Consumption

The Mexican market values low operating costs. We include:

- High-efficiency boiler system

- Steam recycling

- Automated curing control

These features reduce fuel usage by 12–18%.

✓ Strong and Durable Equipment

All structural parts undergo:

- Anti-rust treatment

- High-temperature paint

- Heat-resistant components

Designed for 26–30 years of lifespan, ideal for long-term industrial operation.

✓ Competitive Production Cost

AAC production cost in Mexico: USD 46–60/m³

Market selling price: USD 80–110/m³

→ ROI typically achieved within 2.5–3 years.

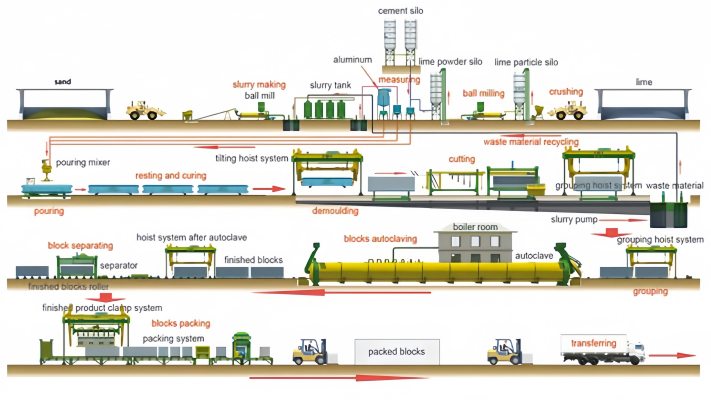

Main Equipment Used in This AAC Plant

The delivered equipment includes:

- Automatic raw material batching system

- Slurry mixing system

- Casting and pre-curing system

- Tilting crane

- Horizontal & vertical cutting machines

- Side plate return conveyor

- Autoclave (ф2.85 × 26 m × 4 sets)

- Boiler system

- Block separating & packing system

- Siemens PLC control system

Complete Production Process

- Raw material batching

- Mixing & pouring

- Pré-cura

- Tilting & demolding

- Vertical cutting

- Horizontal cutting

- Grouping & autoclave loading

- Autoclave curing (steam pressure 1.2–1.4 MPa)

- Unloading & separating

- Packing & storage

Each step is automated to maintain consistency and reduce waste.

Project Service Process — From Inquiry to Commissioning

Step 1: Initial Consultation (January 2024)

- Land evaluation

- Capacity selection

- Cost estimation

- Feasibility study support

Step 2: Design & Technical Proposal (February 2024)

- 3D factory layout

- Utility consumption report

- Production cost simulation

Step 3: Equipment Manufacturing (March–April 2024)

- Machine fabrication

- Cutting system precision testing

- Autoclave pressure test

Step 4: Shipment from Qingdao to Manzanillo Port (May 2024)

- 38 containers total

- Full tracking from departure to delivery

Step 5: Installation in Querétaro (June–July 2024)

- 6 engineers sent to Mexico

- Steel structure setup

- Electrical & piping setup

- Commissioning

Step 6: Training & Trial Operation (August 2024)

- Operator training

- Production optimization

- Quality control setup

Step 7: Official Production Start (September 2024)

Plant reached 95% designed capacity within 10 days.

Results After Commissioning

After full start-up, the customer achieved:

- Daily Output: 520–560 m³

- Block Breakage Rate: < 2.8%

- Energy Savings: 15% compared to the initial estimation

- Stable Curing Results: High compressive strength, uniform density

- Production Cost Optimization: Reduced operating cost by USD 3.1 per cubic meter

- Fast Market Expansion: Sold to Querétaro, Guanajuato, Puebla, Mexico City

This AAC plant quickly became one of the leading suppliers in central Mexico.

What Our Client Says?

“Your AAC production line has been running extremely well since installation.

The cutting accuracy is excellent, energy consumption is lower than expected, and the automation level helped us save a lot of labor costs in Querétaro.

We are very satisfied with the overall quality and stability of the equipment.”

— General Manager, EcoBuild Materials S.A., Querétaro, Mexico

Porquê escolher-nos?

✔ 20+ Years of AAC Manufacturing Expertise

We are one of the earliest AAC machinery manufacturers with a global reputation.

✔ Exported to Over 80 Countries

Including the USA, Canada, Brazil, Chile, Peru, Saudi Arabia, UAE, and India.

✔ True Turnkey AAC Plant Supplier

Design → machinery → installation → commissioning → after-sales support.

✔ High Automation, Low Labor Requirement

Perfect for countries where industrial labor is becoming more expensive.

✔ Custom Machinery for Local Climate & Regulations

Optimized for Mexico’s hot climate and seismic construction needs.

✔ Competitive Pricing, High ROI

Premium-quality equipment with significantly lower investment than European suppliers.

Start Your AAC Block Manufacturing Plant?

Whether you are planning a pequeno, medium, ou large-scale AAC factory, we can provide:

- Feasibility report

- Plant design

- Equipment configuration

- Cost analysis

- Turnkey delivery and installation

- Long-term technical support

Contact us to get a complete proposal for your AAC block making machine project.