An 80,000 CBM/year AAC block plant is a small-to-medium production line designed to manufacture up to 80,000 cubic meters of AAC blocks per year. This capacity is ideal for:

- Local construction markets

- Small developers

- New AAC manufacturing investors

- Companies expanding from manual block making to automated AAC production

- Regions with growing housing or infrastructure demand

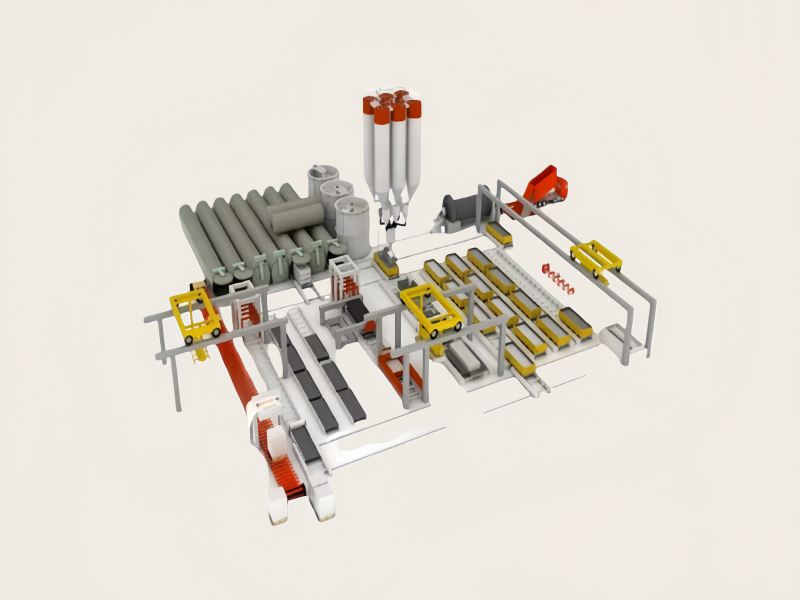

This plant typically includes all essential production systems:

- Raw material processing

- Batching & mixing

- Pouring and pre-curing

- Cutting

- Autoclaving

- Finished product packing

The 80,000 CBM/year capacity ensures consistent supply, while investment costs stay at a manageable level.

Capacity: 80,000 m³/year

Autoclaves: 4-5

End product: AAC Block/Panels

Suitable for: small building material suppliers

Standard: Chinese, ASME, EU, and others

Automation Grade: Semi-automatic, Fully Automatic

Brick Material: Fly Ash/Sand

Brick Dimension: customized

Certificate: ISO 9001

Price Range of 80,000 CBM/Year AAC Block Plant

Based on global market research and previous project experience, the investment range for an 80,000 CBM/year AAC production line is USD 450,000 – 900,000. The exact price depends on:

3.1. Automation Level

- Semi-automatic (lower investment)

- Fully automatic (higher output stability)

3.2. Raw Material Type

- Sand-based systems require additional grinding equipment

- Fly ash-based systems reduce certain equipment needs

3.3. Building and Civil Construction Costs

Although not included in machine cost, customers must budget for:

- Factory workshop

- Foundation

- Steam pipelines

- Electrical installation

3.4. Equipment Configuration

Examples:

| Equipment Type | Cost Impact |

|---|---|

| Standard cutting machine | Low–Medium |

| CNC cutting machine | Medium–High |

| Single autoclave | Low |

| Multiple autoclaves | Faster output, higher cost |

3.5. Local Installation & Training Costs

We provide:

- On-site installation

- Commissioning

- Worker training

- 24/7 after-sales support

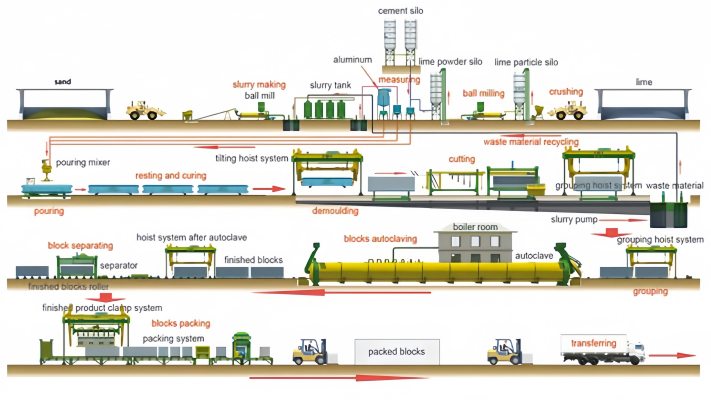

Process of 80,000 m3/Year AAC Block Production Line

Below is the complete workflow used in small AAC plants.

Step 1 — Raw Material Storage & Batching

Cement, lime, gypsum, fly ash/sand are stored in silos or ground storage and fed into weighing systems.

Step 2 — Slurry Mixing

Materials are blended into slurry using a high-efficiency mixer. Aluminum powder is added precisely to ensure correct density and strength.

Step 3 — Casting

Slurry is poured into moulds. Rising and foaming occur naturally during pre-curing.

Step 4 — Pre-Curing (2–3 hours)

The “green cake” becomes semi-solid and ready for demoulding.

Step 5 — Demoulding & Tilting

The mould is tilted 90 degrees, and the green body is separated from the mould.

Step 6 — Cutting

The green cake is cut horizontally and vertically into precise block sizes. Block tolerance is usually ±1.5mm to ±3mm, depending on the cutting system.

Step 7 — Autoclaving (8–12 hours)

Blocks are loaded into autoclaves and cured using saturated steam at 1.2–1.4 MPa.

This process ensures high compressive strength (3.0–4.5 MPa).

Step 8 — Block Packing

Finished blocks are separated, stacked, and packed for delivery.

Key Advantages of a 80,000 CBM/Year AAC Block Plant

This production scale is particularly attractive because it offers clear benefits in terms of cost, operation, efficiency, and market adaptability.

1. Optimized Investment for Faster ROI

Compared with a mini AAC plant (30,000–50,000 CBM/year), the 80,000 CBM plant provides significantly higher profitability without proportionally increasing the total investment.

- Lower cost per cubic meter

- Faster payback period (18–28 months typical)

- Higher production efficiency

2. Stable, Reliable Output

The plant can deliver 220–260 m³ of AAC blocks per day, ideal for stable urban construction supply.

3. Flexible Raw Materials

Suitable for:

- Sand

- Fly ash

- Cement

- Lime

- Gypsum

- Aluminum powder

This flexibility allows customers to minimize raw material cost based on local availability.

4. Compact Layout

An 80,000 CBM plant requires relatively smaller land than large-scale facilities.

- Recommended land: 8,000–12,000 m²

- Optimized building layout to reduce logistics waste inside the factory

5. Lower Operational Costs

Due to modern automation and energy-saving systems:

- Reduced labor needs (8–12 workers)

- Lower electricity consumption

- Minimal maintenance downtime

6. High Market Competitiveness

AAC blocks from this plant meet:

- ASTM standards

- IS standards (India)

- EN standards (Europe)

Customers can sell to local contractors, retail building suppliers, or government projects.

Main Equipment in 80,000 CBM/Year AAC Block Plant

Ball Mill: Essential for milling fly ash or sand to the required fineness.

Slurry Mixer: Ensures the homogeneous mixing of various raw materials.

AAC Moulds: Where the slurry is poured to take the shape of the blocks.

Cutting Machines: These include level cutting, vertical cutting, and two-side cutting machines, which accurately shape the blocks.

Autoclave: The heart of the process, where high- temperature steam treatment occurs.

Ferry Cart: Facilitates the movement of materials and semi-products within the plant.

80,000 CBM/Year AAC Block Plant Exported to India

“The cutting accuracy and machine stability exceeded our expectations.

Your engineers guided our team from installation to full production,

and the plant reached stable operation within the first week.”

Location: Gujarat, India

Customer Type: Real estate developer expanding into AAC manufacturing

Plant Capacity: 80,000 m³/year

Configuration: Fully automatic line

Investment: USD 690,000

Land Size: 10,000 m²

Raw Materials: Fly ash + cement + lime

Project Highlights

- Installation completed in 110 days

- CNC cutting system improved block accuracy to ±1 mm

- Designed for low energy consumption with economical steam system

- Daily production capacity: 250–280 m³

Services You Can Get from Us

Customized AAC Block Plant Process and Layout Design:

Our experienced engineers will design a production process and plant layout that maximizes efficiency and productivity while minimizing costs.

AAC Block Machines Manufacturing and Supplying:

We provide high-quality AAC block machines.

Engineering Construction, Equipment Installation, Personnel Training:

We offer turnkey solutions that include engineering construction, equipment installation, and comprehensive personnel training. Our team will ensure that your plant is up and running smoothly in no time.

Trial production of whole AAC plant:

Before handing over the factory to you, we will conduct a trial production of the production line equipment to ensure that everything is running normally.

Hot-Sale Small Scale AAC Block Plant

50,000 m³ Small Scale AAC Block Plant

Cost: $300,000-$600,000

Delivery time: 3-4 months

Advantages: Quick return on investment, low barrier to entry, the ability to rent land for factory construction, and manageable staff size.

Suitable for: Individual entrepreneurs and small and medium-sized enterprises.

Why Choose Us as Your AAC Production Line Manufacturer?

Many suppliers claim they can provide AAC plants, but few have real technical strength and full in-house production capabilities. Here’s why clients in more than 20+ countries choose us:

✔ 100% In-House Manufacturing

All key equipment — moulds, autoclaves, cutting systems — are produced in our factory, ensuring:

- better quality

- faster delivery

- lower maintenance cost

- long-term spare parts support

✔ 20+ Years Professional AAC Engineering Experience

We provide:

- feasibility analysis

- raw material testing

- block formula guidance

- plant design layout

- installation & commissioning

- worker training

Our engineers have successfully completed AAC installations in Asia, Africa, Middle East, and South America.

✔ Custom Plant Design

- Factory layout drawings

- Production flow diagrams

- Energy consumption reports

- Raw material mix ratio guidance

✔ Advanced Cutting Technology

Our cutting machines provide:

- smooth block surfaces

- accurate dimensions

- minimal waste

- stable output

Cutting quality directly affects block value — this is where our equipment stands out.

✔ Strong Export Experience

We have supplied AAC plants to:

India, Bangladesh, Pakistan, Vietnam, Indonesia, UAE, Saudi Arabia, Kenya, Nigeria, Egypt, Kazakhstan, Russia, Mexico, Peru, South Africa, Tanzania…

We understand different countries’ voltage, boiler standards, safety regulations, and shipping requirements.

✔ Quick Response After-Sales Service

We provide:

- video support

- remote guidance

- on-site engineer service

- spare parts supply

Most issues are solved within 24–72 hours.

Top 5 Manufacturers of Mini AAC Block Plant

1. Guangxi Hongfa Heavy Industry Machinery Co., Ltd.

- Main Products: AAC block/ALC wall panel making plants (with an annual output of 50,000 – 500,000 m³), concrete mixing plants, and block forming machines.

- Features: It offers customizable semi-automatic or fully automatic Small Scale AAC Block Plant, equipped with PLC control systems and compatible with 380V/220V power supplies. The products have obtained CE certification. The company provides overseas installation, commissioning, and training services, and has a short after-sales service cycle.

- Suitable Enterprise Types: Startups with limited budgets, small and medium-sized building material factories planning to expand their product portfolios, and export-oriented enterprises.

2. Henan Zhengyi Building Material Machinery Manufacturing Co., Ltd.

- Main Products: AAC block/panel manufacturing plants (annual output of 50,000 – 300,000 m³), cutting machines, and autoclaves.

- Features: The equipment adopts a modular design, and customers can optionally equip it with Siemens motors or Schneider PLCs. It is equipped with a waste heat recovery system that reduces energy consumption by 18%, and its dust emission is less than 10mg/m³. It also supports customization for alpine or seismic regions.

- Suitable Enterprise Types: Enterprises focusing on energy conservation and environmental protection, as well as manufacturers planning to enter overseas markets such as Central Asia and Russia.

3. Dongyue Machinery Group Co., Ltd.

- Main Products: AAC block/panel manufacturing plants (annual output of 50,000 – 300,000 m³).

- Features: The production lines absorb German technology and have a high level of automation. The company has nearly 500 project cases worldwide and provides one-stop services including planning, installation, commissioning, and training. Its products have obtained CE, ISO, and SGS certifications.

- Suitable Enterprise Types: Enterprises pursuing stable and efficient production and aiming to reduce operating costs, especially those suitable for large-scale replicated production.

4. Jiangsu Huilong International Co., Ltd.

- Main Products: AAC block manufacturing plants (annual output of 30,000 – 300,000 m³), cutting machines, molds, and autoclaves.

- Features: Multiple specifications of molds are available, with an hourly output ranging from 1,280 to 12,000 blocks. The company also provides factory design and automation solutions.

- Suitable Enterprise Types: Small and medium-sized enterprises with limited factory space and expecting to launch production quickly, as the equipment supports flexible capacity adjustment.

5. Henan Lanshan Machinery Manufacturing Co., Ltd.

- Main Products: Small Scale AAC block Plant.

- Features: The equipment has a small footprint and low investment, making it suitable for the initial operation stage. It also supports customized configurations.

- Suitable Enterprise Types: Individual operators or small processing plants that are entering the AAC field for the first time and face constraints in capital and site.

Want to Start Your AAC Block Plant?

We can provide:

- Full project cost list

- Feasibility report

- Layout drawing/3D proposal

- ROI analysis

- Equipment configuration

Related AAC Plant

Related: 50000 m³ AAC Block Plant, 20,000 m3/Year AAC Block Plant, AAC Plant Manufacturer