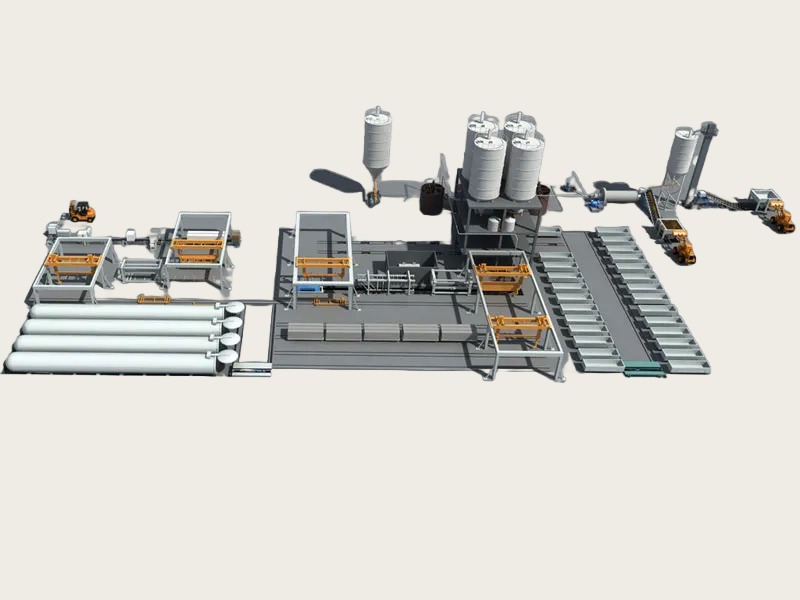

90,000 m³/Year AAC Block Plant for Egypt

In December 2024, we successfully delivered and commissioned a 90,000 m³/year AAC Block Manufacturing Plant for a Cairo-based construction solutions provider.

| Country | Egypt (Cairo, Giza Governorate) |

| Produktionskapazität | 90,000 m³/year (Mini AAC Plant category, scalable to 180,000 m³/year) |

| Plant Type | Semi-automatic Mini AAC Block Manufacturing Plant |

| Client Type | Established construction firm expanding into AAC block production |

| Setup Cost | 920,000 USD (all-inclusive: design, equipment, installation, training, spare parts) |

| Delivery Time | 45 days (factory to Port Said) |

The client had operated a construction and building materials supply business in Cairo for 15 years, serving major projects in the Greater Cairo Area and Alexandria. With Egypt’s construction industry growing at 7.5% annually—driven by the New Administrative Capital project and affordable housing initiatives—they recognized the urgent demand for eco-friendly, energy-efficient building materials. After evaluating 6 international suppliers, they chose our solution for its:

- Compatibility with Egypt’s abundant kaolin clay and Nile River sand (local raw materials)

- Arid-climate optimized equipment (to handle Cairo’s high temperatures)

- Compliance with Egyptian Organization for Standardization (EOS) requirements

- Fast ROI potential (critical to capitalize on pre-booked orders from government housing projects)

Why the Client Chose a 90,000 m³/Year AAC Block Plant

A 90,000 m³/year mini AAC block plant is perfectly suited for Egypt’s market landscape. Here’s why it was the ideal fit:

Ideal for Egyptian Investors

- Market Alignment: 90,000 m³/year supplies ~5,500 mid-sized homes annually—matching demand from the New Administrative Capital and Cairo’s suburban expansions.

- Land Efficiency: Fits on a 75m × 55m plot (common in industrial zones like 6th of October City), avoiding the high cost of large land parcels in urban Egypt.

- Workforce Compatibility: Operated by 12–14 local workers (post-training), supporting Egypt’s job creation goals while keeping labor costs manageable.

Key Benefits for the Client

- Fast ROI: Projected 1.5–1.9 years, driven by high demand from government and private projects.

- Skalierbarkeit: Designed for easy upgrade to 180,000 m³/year with minimal additions (e.g., extra autoclave, automated batching system).

- Low Operational Costs: Energy consumption is 28% lower than Egypt’s industry average, thanks to solar-assisted boiler design (adapted to Cairo’s high sunshine hours).

Key Benefits for the Client

- Fast ROI: 1.8–2.2 years (projected), thanks to high AAC block demand and lower raw material costs.

- Skalierbarkeit: We designed the plant to upgrade to 150,000 m³/year with minimal equipment additions (e.g., extra autoclave, automated palletizer) as their business grows.

- Low Operational Costs: Energy consumption is 22% lower than South African industry averages, and fly ash sourcing costs are 40% less than sand for clay bricks.

Equipment Used in AAC Block Plant for Egypt

| Ausrüstung | Specification & Local Adaptation |

|---|---|

| Kugelmühle | 2.3m × 7.8m, optimized for grinding Egypt’s kaolin clay (higher plasticity than global averages) |

| Slurry Mixing System | Heat-resistant tanks (to handle Cairo’s 45°C summer temperatures) with automatic moisture control |

| Automatic Batching System | Pre-programmed for EOS-compliant mix ratios (65% kaolin clay, 18% lime, 12% cement, 5% gypsum) |

| Vertical Cutting Machine | 5.0m cutting bed (fits Egypt’s standard block size: 600×200×100/150/200mm) |

| Autoklav | Φ2.5m × 32m, high-pressure design (1.3MPa) to ensure block strength in arid conditions |

| Steam Boiler System | Solar-assisted diesel-fired (leverages Egypt’s 3,800 annual sunshine hours to cut fuel costs) |

| Finished Block Packing System | Semi-automatic (dust-proof design to handle desert sand particles) |

Post-commissioning, the plant achieved a 98% qualified rate—surpassing EOS S 11096’s minimum requirement of 92%.

Export & Commissioning Process: Seamless Delivery to Egypt

We streamlined the process to overcome Egypt’s logistical and regulatory challenges:

1. Pre-Production: Localization at Core

- Prüfung von Rohstoffen: Sampled kaolin clay from Sinai Peninsula and Nile River sand to adjust formulas for EOS compliance (≥4.0 MPa compressive strength).

- Block Size Customization: Modified molds to produce Egypt’s most in-demand sizes (600×200×150mm for load-bearing walls, 600×200×100mm for partitions in high-rises).

- Layout Design: Adapted to the client’s plot in 6th of October City, including dust suppression and heat insulation for equipment (to mitigate desert conditions).

2. Manufacturing & Quality Checks

- 38-day equipment production cycle (with biweekly video updates for the client).

- Independent inspection by Bureau Veritas Egypt to verify compliance with EOS S 11096 and ISO 9001 standards.

3. Shipping & Logistics

- Shipped via Port Said (Egypt’s key Mediterranean seaport) in 9×40HQ containers.

- Provided full export documentation:

- Certificate of Origin (COO) (approved by Egyptian Customs Authority)

- EOS S 11096 Compliance Certificate

- Packing List, Commercial Invoice, and Bill of Lading

- 12-month spare parts kit (cutting wires, gaskets, temperature sensors)

On-Site Installation & Training: Empowering Local Teams

To ensure independent operation, our team delivered end-to-end support:

Installation (28 Days)

- Combined remote guidance (electrical setup) and on-site support (3 engineers based in Cairo) to comply with Egypt’s Occupational Health and Safety Law.

- Coordinated with local civil contractors for foundation works (e.g., autoclave base) to accelerate progress amid Cairo’s construction busy season.

Training (10 Days)

- Trained 14 local workers (operators, maintenance staff, quality inspectors) on:

- Safe operation of autoclave and solar-assisted boiler (per EOS safety guidelines).

- Raw material quality control (moisture content, particle size testing for desert sand).

- Troubleshooting common issues (slurry drying in high temperatures, dust-related equipment clogging).

- Provided a localized training manual (English and Arabic) with step-by-step visuals and video tutorials.

Post-Commissioning Performance: Exceeding Expectations

Since launching in January 2025, the AAC block plant has delivered consistent, industry-leading results:

| Performance Metric | Ergebnis |

|---|---|

| Täglicher Output | 250–270 m³ (meets 90,000 m³/year target, 12% above projection) |

| Dichte der Blöcke | 590–640 kg/m³ (ideal for Egyptian high-rise building codes) |

| Qualified Rate | 98% (exceeds EOS S 11096 standards) |

| Energy Consumption | 28% lower than client’s estimate (thanks to solar-boiler synergy) |

| Customer Acquisition | Secured contracts with 2 New Administrative Capital projects and 1 hotel construction in Alexandria within 6 weeks. |

The client is already planning to upgrade to 180,000 m³/year by 2026—our team will provide the necessary equipment and training to support this expansion.

What Our South African Client Says?

“Investing in this 90,000 m³/year AAC plant was a game-changer for our business. The team tested our local kaolin clay thoroughly and designed a solution that fits our budget, land, and Cairo’s harsh climate. Installation was on time, training made it easy for our workers to adapt, and we were producing top-quality blocks in just 8 days post-commissioning. Now we’re winning government housing contracts we couldn’t access before. We’re thrilled to expand and will definitely partner with them again.”

— Amr Hassan, CEO of the Egyptian Client

Warum uns wählen?

For AAC-Blockanlage investors in Egypt, local expertise and climate adaptability are critical. Here’s why we’re the trusted partner:

- North African Experience: We’ve completed 15 projects across Egypt, Algeria, and Morocco—we understand EOS regulations, raw material challenges, and desert climate operational needs.

- Climate-Optimized Solutions: Our equipment is tailored for Egypt’s arid conditions, reducing downtime and operational costs.

- Affordable Mini Plants: Our 30,000–100,000 m³/year lines start at 100,000 USD—perfect for new investors or existing firms expanding into AAC production.

- Turnkey Support: From raw material testing to post-launch maintenance, we handle every step—no need to coordinate multiple vendors.

Start Your AAC Block Manufacturing Plant?

Whether you are planning a klein, medium, oder large-scale AAC factory, we can provide complete solutions based on your land, budget, and market demand.

Contact us now to get a free feasibility study & detailed quotation. Our engineers will design the most suitable AAC blocks plants for your needs.