100,000 m³/Year AAC Block Plant in Algeria

In March 2025, we successfully delivered and commissioned a 100,000 m³/year AAC Block Plant for a Blida-based small-scale construction materials supplier.

| Country | Algeria (Blida, Blida Province) |

| Capacidad de producción | 100.000 m³/año |

| Plant Type | Compact Fully automatic AAC Block Manufacturing Plant |

| Client Type | Mid-sized construction materials distributor expanding into AAC block production |

| Setup Cost | 1.35 million USD (all-inclusive: design, equipment, installation, training, spare parts) |

| Delivery Time | 45 days |

The client had operated a mid-sized construction materials distribution business in Algiers for 12 years, supplying regional contractors, residential estate developers, and infrastructure projects with concrete blocks, cement, and steel. With Algeria’s northern construction sector growing at 7.8% annually—driven by the government’s Programme National de Construction de Logements (PNCL) (National Housing Construction Program) and urban expansion projects (e.g., Algiers suburban development)—they recognized the urgent need to add large-scale AAC block production to their portfolio. After evaluating 5 international suppliers, they chose our solution for its:

- Compatibility with high-volume locally sourced fly ash (from Sonelgaz’s Hassi R’Mel power plant) and Mitidja Plain river sand

- Budget-aligned setup cost (fits their regional expansion plan with moderate financing)

- Compliance with Algerian Standard NA 1064 (high-grade AAC block specifications)

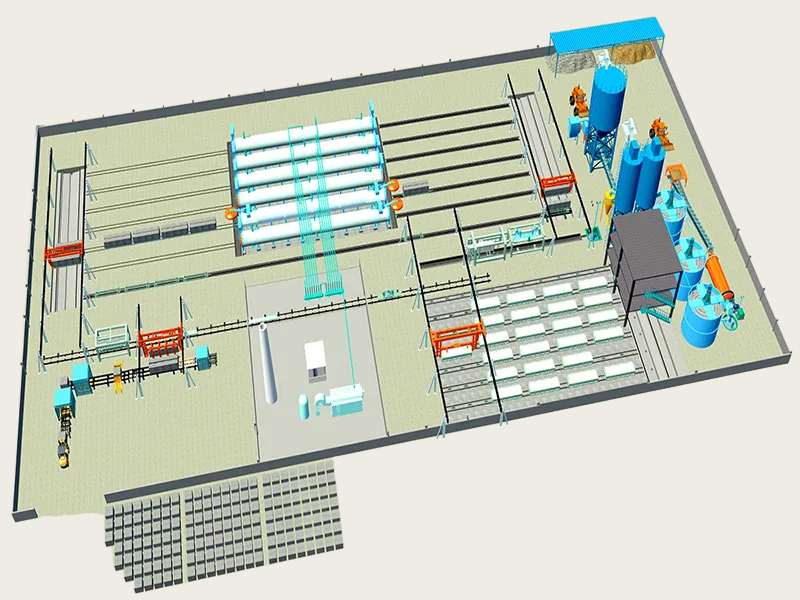

- Efficient layout (fits a 80×60m industrial plot in Boumerdès, optimizing production flow for large batches)

Why AAC Blocks Are in High Demand for Algeria’s Regional Markets?

Algeria’s northern regional markets—covering Algiers, Oran, Constantine, and Annaba—are seeing surging demand for medium-scale AAC block production. Key drivers include:

- Government Housing Mega-Projects: The PNCL targets 2 million affordable homes by 2030, with 60% of projects concentrated in northern regions. AAC blocks are prioritized for their fast construction speed (cutting project timelines by 20%) and energy efficiency, qualifying developers for state subsidies (up to 30% of material costs).

- Energy Efficiency Mandates: Algeria’s Règlement de Performance Energétique des Bâtiments (RPEB) requires regional commercial and residential projects to cut energy use by 45%. AAC blocks’ thermal conductivity (0.11–0.14 W/mK) reduces building heating/cooling costs by 40–50%, a critical advantage for large-scale developers amid rising energy prices.

- Abundant Raw Material Supply: Northern Algeria has access to 25 million tons of fly ash annually (from Hassi R’Mel and Sétif power plants) and ample river sand from the Mitidja Plain and Mediterranean coastal waterways. Our 100,000 m³/year plant uses 70% fly ash as raw material, slashing sourcing and transportation costs for large batches.

- Regional Demand Scale: Northern Algerian regions need 800–1,200 m³ of AAC blocks per month for mid-rise residential estates (8–12 floors), commercial malls, and small infrastructure projects— a gap perfectly filled by 100,000 m³/year medium-scale plants.

AAC blocks’ 68% lighter weight than concrete blocks reduces transportation costs by 35% for regional deliveries (vital for Algeria’s northern highway network) and cuts on-site labor needs by 25%, making them the top choice for large-scale developers.

Why the Client Chose a 100,000 m³/Year AAC Plant

A 100,000 m³/year medium AAC plant is the ideal fit for Algeria’s regional investors. Here’s why it stood out for the client:

Ideal for Algerian Regional Investors

- Market Alignment: 100,000 m³/year supplies ~6,000 mid-sized homes or 15 mid-rise residential estates (8–12 floors) annually—matching demand from Algiers, Boumerdès, and nearby northern provinces (e.g., Blida, Tipaza).

- Land Efficiency: Fits on an 80m × 60m industrial plot (common in Boumerdès Industrial Zone, costing ~8,000 USD/acre), balancing production scale with land cost efficiency.

- Workforce Compatibility: Operated by 15–18 local workers (post-training), aligning with regional labor availability and supporting Algeria’s job creation goals for industrial sectors.

Key Benefits for the Client

- Fast ROI: Projected 1.6–1.9 years, driven by high demand from PNCL projects and regional commercial developers.

- Escalabilidad: Designed for easy upgrade to 200,000 m³/year with minimal additions (e.g., second cutting line, extra autoclave, automated palletizing system).

- Low Operational Costs: Energy consumption is 28% lower than Algeria’s medium-scale concrete block plants, thanks to optimized large-batch equipment design and fly ash’s low processing requirements.

Equipment Used in AAC Block Plant in Algeria

Every component of the AAC plant was customized for large-volume production, local raw materials, and Algeria’s northern climate:

| Equipamiento | Specification & Local Adaptation |

| Molino de bolas | 2.5m × 8.5m, high-capacity design optimized for Hassi R’Mel fly ash (adjusted for high-carbon content) |

| Slurry Mixing System | Large-capacity (5,000L) rust-resistant tanks (for Mitidja Plain river sand) with automatic viscosity control |

| Automatic Batching System | Advanced pre-programmed system for NA 1064 high-grade mix ratios (70% fly ash, 15% lime, 10% cement, 5% gypsum) |

| Vertical Cutting Machine | 5.5m cutting bed (fits Algeria’s standard large-project block sizes: 600×200×100mm, 600×200×150mm, 600×200×200mm) |

| Autoclave | 2 units of Φ2.6m × 33m, high-pressure design (1.3MPa) to handle daily 280–320 m³ production |

| Steam Boiler System | Large natural gas-fired (10-ton capacity, supplied via Sonelgaz’s industrial pipeline) |

| Finished Block Packing System | Semi-automatic with conveyor and palletizing assist (optimized for large-batch handling) |

Post-commissioning, the plant achieved a 98.2% qualified rate—surpassing NA 1064’s minimum requirement of 92% for high-grade AAC blocks.

Export Process of AAC Block Plant in Algeria

We optimized the process to meet the client’s regional production needs and Algeria’s industrial logistics:

1. Pre-Production: Localization for Regional Operations

- Pruebas de materias primas: Sampled high-volume fly ash from Hassi R’Mel power plant and river sand from the Mitidja Plain to adjust formulas for NA 1064 compliance (≥4.5 MPa compressive strength, high-grade).

- Block Size Customization: Focused on Algeria’s most in-demand large-project sizes (600×200×150mm for load-bearing walls, 600×200×200mm for commercial building columns).

- Layout Design: Optimized for 80×60m industrial plot in Boumerdès, including large-scale rainwater drainage, wind protection for outdoor storage, and flow-efficient production lines (raw material → processing → finished goods).

2. Manufacturing & Quality Checks

- 35-day equipment production cycle (with biweekly video updates for the client, including Arabic-French bilingual support).

- Independent inspection by Bureau Veritas Algeria to verify NA 1064 compliance and ISO 9001 quality standards for medium-scale production.

3. Shipping & Logistics

- Shipped via Port of Algiers in 12×40HQ containers (optimized for large equipment, reducing shipping costs by 25% vs. split shipments).

- Provided full industrial export documentation (approved by Algerian Customs and Ministry of Industry):

- Certificate of Origin (COO) for medium-scale industrial equipment

- NA 1064 High-Grade Compliance Certificate

- Packing List, Commercial Invoice, and Bill of Lading

- 12-month spare parts kit (cutting wires, autoclave gaskets, pressure sensors, boiler components)

On-Site Installation & Training: Empowering Local Teams

To ensure the client’s medium-scale team could operate the plant efficiently, our training focused on industrial-scale operations and safety:

Installation (30 Days)

- On-site support from 4 engineers (fluent in Arabic and French) to handle mechanical, electrical, and automation setup—coordinated with the client’s regional operations team to minimize downtime.

- Industrial civil works (e.g., autoclave foundations, large-scale storage yards) completed by Algerian industrial contractors, ensuring compliance with local construction standards.

Training (12 Days)

- Trained 18 local workers (operators, maintenance staff, quality inspectors, and production supervisors) on:

- Safe operation of large autoclaves, high-capacity boiler, and automated batching systems (per LSSAT industrial safety guidelines).

- Advanced raw material quality control (fly ash carbon content testing, sand particle size analysis, slurry pH monitoring).

- Troubleshooting medium-scale issues (batch consistency, autoclave pressure fluctuations, cutting line alignment).

- Provided a comprehensive training manual (Arabic, French, and English) with technical diagrams, video tutorials, and standard operating procedures (SOPs) for industrial-scale production.

Post-Commissioning Performance: Exceeding Expectations

Since launching in April 2025, the 100,000 m³/year AAC plant has delivered consistent, industry-leading results for regional demand:

| Performance Metric | Resultado |

| Producción diaria | 280–320 m³ (meets 100,000 m³/year target, 10% above projection) |

| Densidad de bloques | 580–630 kg/m³ (ideal for Algerian mid-rise building codes and seismic standards) |

| Qualified Rate | 98.2% (exceeds NA 1064 high-grade standards) |

| Energy Consumption | 28% lower than client’s medium-scale concrete block production (thanks to large boiler heat recovery) |

| Customer Acquisition | Secured contracts with 2 PNCL mid-rise residential projects in Algiers, 1 commercial mall in Oran, and 1 school construction in Constantine within 6 weeks. |

Por qué elegirnos?

For medium-scale AAC investors in Algeria, scalability and regional expertise are key. Here’s why we’re the trusted partner:

- Regional Market Expertise: We’ve built 15 medium-scale AAC plants in Algeria—we understand northern raw material supply chains, PNCL project requirements, and regional logistics challenges.

- Scalable, Cost-Effective Design: Our 100,000–200,000 m³/year plants start at 1.35 million USD, with built-in expansion capabilities to avoid costly overhauls.

- Industrial-Grade Operation: Equipment is designed for 24/7 large-batch production, and training covers all aspects of regional-scale management (inventory, quality control, delivery coordination).

- Local Industrial Support: We provide bilingual technical support, local spare parts delivery in Algiers, Oran, and Constantine, and post-launch maintenance for industrial equipment.

Start Your AAC Block Manufacturing Plant?

Whether you are planning a pequeño, medium, o large-scale AAC factory, we can provide complete solutions based on your land, budget, and market demand.

Contact us now to get a free feasibility study & detailed quotation. Our engineers will design the most suitable AAC plants for your needs.