150,000 m³/Year AAC Block Production Line in Spain

We recently completed a 150,000 CBM/year AAC block production line for a client in Spain. This project was designed to meet the increasing demand for lightweight, thermally efficient, and energy-saving building materials in the Spanish residential and commercial construction market.

Our solution helped the customer quickly enter the AAC industry with:

✔ A fully automated medium-scale production line

✔ Low energy consumption

✔ CE-certified equipment

✔ High-precision cutting technology

✔ Turnkey installation, training, and commissioning

Why the Spanish Customer Chose a 150,000 CBM/Year AAC Plant?

After a detailed market analysis, the investor determined that a medium Planta de hormigón celular best matched the local market:

Reasons for choosing this capacity:

- Spain’s AAC demand is steadily growing but still developing → 100,000–200,000 CBM/year is ideal

- Fits EU insulation and carbon-neutral construction standards

- Highly competitive for both local building contractors and distributors

- Lower operational cost while maintaining excellent profitability

- Allows expansion to 200,000 CBM/year with minimal system upgrades

Investment Range: USD 1.2M – 2.3M

Best For: Regional supply centers across Spain

Customer Requirements Before Purchasing

During the consultation process, the Spanish client raised several critical questions:

Customer Concerns

- How to achieve EU-compliant density and strength levels?

- How energy-efficient is the autoclave system?

- What is the cost per m³ of AAC blocks in Spain?

- What is the ROI and expected payback period?

- How to reduce labor cost through automation?

- How to manage factory layout in a narrow space?

- Are spare parts and after-sales services available in the EU?

We provided full technical solutions, cost calculations, and a customized factory layout based on the customer’s land size.

Final Configuration of AAC Block Production Line in Spain

The customer selected our 150,000 CBM/year fully automated configuration, including:

Key Equipment Supplied

- Automatic batching & pouring system

- High-precision slurry & cement dosing system

- Advanced AAC cutting machine (vertical + horizontal cutting)

- 8-set autoclave group with energy-saving steam pipeline design

- Tilting, demolding, and grouping systems

- Fly ash/river sand processing line

- Automated packing & palletizing system

Features of This Configuration

✔ Fully automatic PLC control

✔ 15–20% lower power consumption vs. local manufacturers

✔ Perfect smooth cutting surface, suitable for thin-bed mortar construction

✔ CE-certified to meet EU regulations

✔ 30% reduction in labor through smart automation

Production Line Advantages for the Spanish Market

1. Excellent Thermal Insulation

AAC blocks significantly reduce energy consumption in Spanish summer and winter climates.

2. Fire Resistance (Up to 4 hours)

Ideal for residential buildings, public facilities, and warehouse construction.

3. Lightweight and Easy to Install

Speeds up construction and reduces structural load on older buildings.

4. Meets Spain’s Technical Building Code (CTE)

Especially for energy efficiency (HE1) and structural safety.

5. High Profit Margin

- Average AAC block selling price in Spain: USD 48–60 per m³

- Average production cost: USD 22–28 per m³

- Profit: USD 20–30 per m³

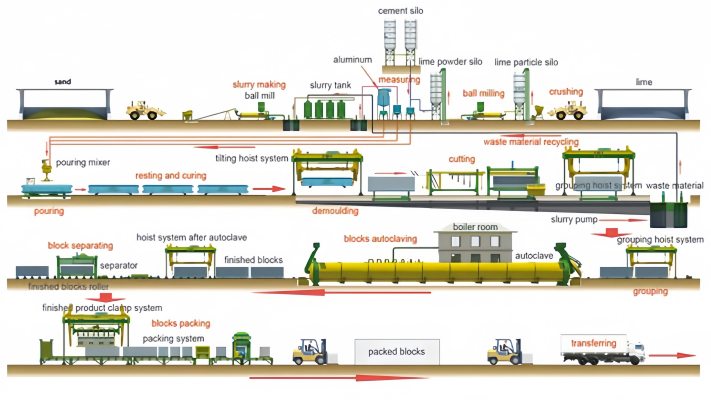

Complete Production Process

- Sand processing & grinding

- Slurry mixing

- Mold casting

- Precurado

- Tilting & demolding

- Horizontal & vertical precision cutting

- Grouping & autoclaving

- Steam curing cycle

- Final inspection

- Automated packaging & palletizing

Our engineers ensured stable production from day one.

Installation & Commissioning in Spain

Our engineers traveled to the customer’s site in Spain to provide:

- Full plant installation

- Equipment commissioning

- Staff training

- Recipe optimization using local sand and lime

- Production testing and quality control setup

Result: The plant achieved stable production within 32 days, meeting all Spanish customer expectations.

What Our Client Says?

“The equipment quality and automation level are exactly what we needed for the Spanish market.

Your engineers worked professionally during installation, and the cutting precision far exceeds local alternatives. Our team is now producing stable, high-quality AAC blocks every day.”

Por qué elegirnos?

We are one of the most experienced AAC production line suppliers in China:

✔ 20+ years manufacturing

✔ 80+ countries exported

✔ CE-certified equipment

✔ Turnkey EPC service

✔ Strong R&D and after-sales support

✔ High-quality autoclaves, cutting machines, and batching systems

Start Your AAC Block Manufacturing Plant?

Contact us today for a customized AAC plant design, cost analysis, and turnkey solution tailored to your market.