A Cost-Effective Entry Solution for Small AAC Block Plant Manufacturers

As the demand for lightweight, energy-efficient building materials continues to grow, more investors and building material producers are turning their attention to AAC blocks. For those who want to enter the AAC industry with controlled risk and reasonable investment, a 2000 blocks per day AAC block plant offers a practical and proven solution.

This production capacity is specifically designed for small to medium-scale manufacturers, first-time AAC investors, and traditional block producers looking to upgrade their product portfolio.

What Is a 2000 Blocks Per Day AAC Block Plant?

A 2000 blocks per day AAC block plant is a small-capacity AAC block production line designed to produce approximately 2,000 standard-size AAC blocks within a normal working day.

Depending on block dimensions and density, this capacity typically corresponds to:

- Stable daily output for local market supply

- Flexible operation with one or two shifts

- Annual production suitable for small housing projects and regional distributors

Compared with large AAC production lines, this plant focuses on simplicity, cost control, and operational flexibility, making it ideal for markets where demand is steady but not yet industrial-scale.

Common search terms associated with this solution include:

- small AAC block manufacturing plant

- mini AAC block plant

- low capacity AAC block production line

Who Is the Right Investor for a 2000 Blocks Per Day AAC Block Plant?

This type of AAC block plant is best suited for:

- First-time AAC block manufacturers entering the industry

- Concrete block or clay brick producers upgrading to AAC blocks

- Local building material suppliers serving nearby construction projects

- Small investors seeking fast return with limited financial exposure

- Developing and emerging markets where AAC adoption is growing gradually

For customers who are testing market demand or replacing traditional masonry products, a small AAC block plant provides a manageable and scalable starting point.

Why Choose a 2000 Blocks/Day AAC Block Plant Instead of a Larger Line?

Many investors initially consider larger AAC plants but later realize that a smaller capacity offers several advantages:

- Lower initial investment, reducing financial pressure

- Simpler operation, requiring fewer skilled workers

- Shorter installation and commissioning time

- Faster break-even point, especially in local markets

- Expandable design, allowing future capacity upgrades

For regions where AAC block demand is still developing, starting with a 2000 blocks per day AAC block plant minimizes risk while maintaining production stability.

Matières premières des blocs AAC

- Ciment (ciment Portland): Agit comme un liant primaire, assurant la résistance et la durabilité des blocs. On utilise généralement de l'OPC de qualité 43 ou 53.

- Cendres volantes ou sable: Les cendres volantes constituent le principal matériau siliceux. Les cendres volantes, un sous-produit des centrales électriques au charbon, sont une alternative écologique au sable, car elles fournissent la teneur en silice nécessaire.

- Chaux: Matière calcaire essentielle qui réagit avec d'autres composants pour former la matrice de liaison et contribue aux réactions chimiques pendant la production.

- Gypse: Ajouté en petites quantités pour réguler le temps de prise et améliorer l'ouvrabilité du mélange.

- Poudre ou pâte d'aluminium: Fonctionne comme un agent moussant. Il réagit avec la chaux et l'eau pour produire de l'hydrogène, créant ainsi la structure poreuse et légère caractéristique.

- L'eau: Indispensable pour l'hydratation du ciment et de la chaux, et pour faciliter les réactions chimiques nécessaires à la prise et au durcissement des blocs.

Ces matériaux sont soigneusement dosés et mélangés pour former un coulis, qui est ensuite coulé, pré-cuit, coupé et enfin autoclavé pour produire les blocs AAC finis.

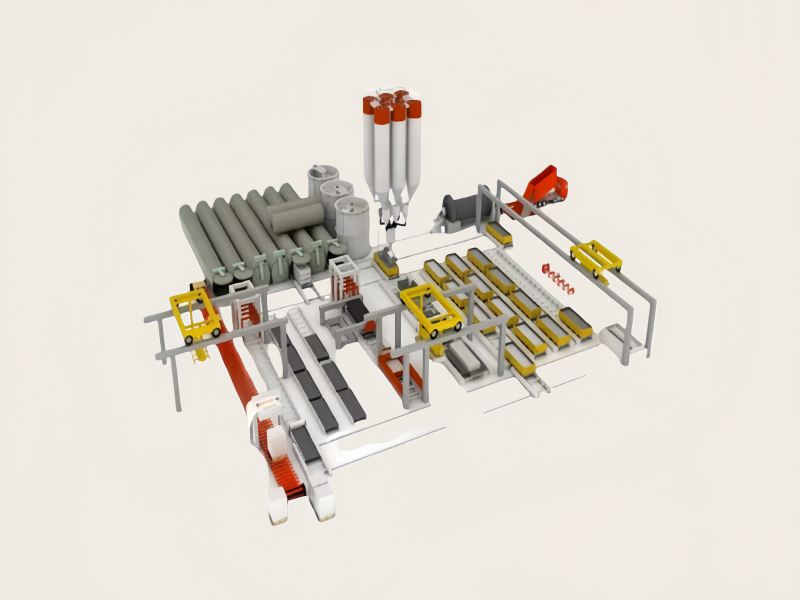

Main Equipment Included

A typical 2000 blocks/day AAC block manufacturing plant includes:

- Raw material preparation and storage system

- AAC batching and mixing system

- Moulds and pouring system

- Pre-curing chamber

- AAC block cutting machine (horizontal and vertical cutting)

- Autoclave system (single autoclave or shared configuration)

The equipment layout emphasizes reliability and ease of maintenance rather than excessive automation.

Automation Level Options

Most customers choose a semi-automatic AAC block plant configuration, which balances investment cost and production efficiency. This setup reduces labor intensity while keeping equipment costs under control.

Production Process of a 2000 Blocks Per Day AAC Block Plant

The AAC block manufacturing process follows standard industrial principles:

- Raw material weighing and batching

- Mixing and slurry preparation

- Pouring into moulds

- Pre-curing for strength development

- Cutting to required block sizes

- Autoclaving for final curing

- Finished block stacking and storage

The production cycle is stable and repeatable, ensuring consistent quality even at small production volumes.

Land Area and Factory Layout Requirements

One of the main advantages of a small AAC block plant is its compact footprint.

Typical requirements include:

- Modest land area suitable for small industrial zones

- Simple factory layout optimized for material flow

- Standard power and water supply

- Boiler and steam system matched to autoclave capacity

In many cases, existing workshops can be adapted for AAC block production with minor modifications.

Investment Cost of a 2000 Blocks Per Day AAC Block Plant

Investment cost depends on configuration and local conditions, but generally includes:

- AAC block plant machinery cost

- Autoclave and boiler system

- Civil construction and foundation work

- Installation and commissioning

Compared with medium and large AAC plants, the 2000 blocks per day AAC block plant price is significantly lower, making it accessible for small investors and family-owned businesses.

Operating Cost and Profit Analysis

Operating costs are mainly driven by:

- Raw material consumption

- Power and fuel usage

- Labor cost

- Routine maintenance

With proper cost control and stable market demand, AAC blocks produced by a small-capacity plant can achieve competitive profit margins. Many investors reach their break-even point faster than expected due to lower fixed costs.

Finished AAC Block Quality and Performance

Despite its small scale, the plant produces AAC blocks that meet industry standards in terms of:

- Density and compressive strength

- Dimensional accuracy

- Thermal insulation and lightweight properties

These blocks are widely used in residential buildings, low-rise commercial projects, and infrastructure applications.

Installation, Training, and After-Sales Support

A reliable AAC block plant supplier typically provides:

- Turnkey project supply

- On-site installation and commissioning

- Operator training for daily production and maintenance

- Spare parts supply and technical support

This ensures smooth startup and long-term stable operation.

Typical Applications and Market Scenarios

A 2000 blocks per day AAC block plant is commonly used for:

- Supplying local housing projects

- Replacing traditional clay bricks or concrete blocks

- Serving rural and semi-urban construction markets

- Gradual expansion into higher-capacity AAC production

Is a 2000 Blocks Per Day AAC Block Plant Right for You?

This plant is a suitable choice if:

- Your budget is limited but you want reliable AAC production

- Your target market is local or regional

- You prefer lower risk and faster return

- You plan to expand capacity step by step

Starting with a small AAC block plant allows investors to gain production experience and market confidence before scaling up.

Autres Usine de fabrication de blocs en vente à chaud

| Production annuelle | Prix (USD) | Configuration de base |

|---|---|---|

| 100,000 m³ | 1.5-1.9 M | Découpe à l'air comprimé, autoclaves de 3×31 m |

| 150,000 m³ | 2.1-2.6 M | Palettisation robotisée, autoclaves de 4×31 m |

| 200,000 m³ | 2.8-3.5 M | Découpe sur six côtés, autoclaves de 4×37 m |

| 300,000 m³ | 4.0-4.8 M | Deux lignes de coupe, autoclaves de 6×37 m |

| 400,000 m³ | 5.5-6.5 M | Autoclaves 8×37 m et plus à retournement d'air entièrement automatique |

Get a Customized 2000 Blocks Per Day AAC Block Plant Solution

Every market has different raw materials, labor costs, and construction demand. A customized 2000 blocks per day AAC block plant solution can be designed based on your specific conditions.

Contact us to receive:

- Customized plant layout design

- Equipment configuration recommendation

- Detailed investment and ROI analysis

- Competitive quotation for your AAC block project

Usine de CAA apparentée

En rapport : Coût de l'usine de blocs AAC, Fabricant d'usine AAC, Machine de fabrication de blocs AAC