Mini AAC plant is used to produce aerated concrete blocks and panels at a fraction of the scale and cost of medium- and large-scale production lines. We offer fully automated and fully automatic small concrete block production lines with annual production capacities ranging from 30,000 to 100,000 m³.

Cost-effective Mini AAC plant is an ideal investment for entrepreneurs with limited budgets, those starting out, or those looking to test the market before making a larger investment.

Mini AAC block production lines offer the advantages of low investment, minimal floor space, and high cost-effectiveness. They also meet quality standards such as those in China, ASME, and the EU.

Capacity: <100,000 m³/year

Autoclaves: 3-4

Factory area: 4000 -5000 m2

End product: AAC Block/Aerated concrete slabs

Capacity: <100,000 cubic meters/year

Standard: Chinese, ASME, EU, and others

Automation Grade: Semi-automatic, Automatic

Brick Material: Fly Ash/Sand

Brick Dimension: customized

Certificate: ISO 9001

What is the Cost of a Mini AAC Plant?

The cost of a Mini AAC Plant varies widely and depends on several factors. Generally speaking, the total investment for a small AAC production line with an annual capacity of 300,000-100,000 cubic meters ranges from $250,000 to $800,000.

- Manual production line in India/Southeast Asia: $250,000–400,000

- Semi-automatic production line in China: $350,000–550,000

- Fully automated production line for European and American CE standards: $600,000–800,000

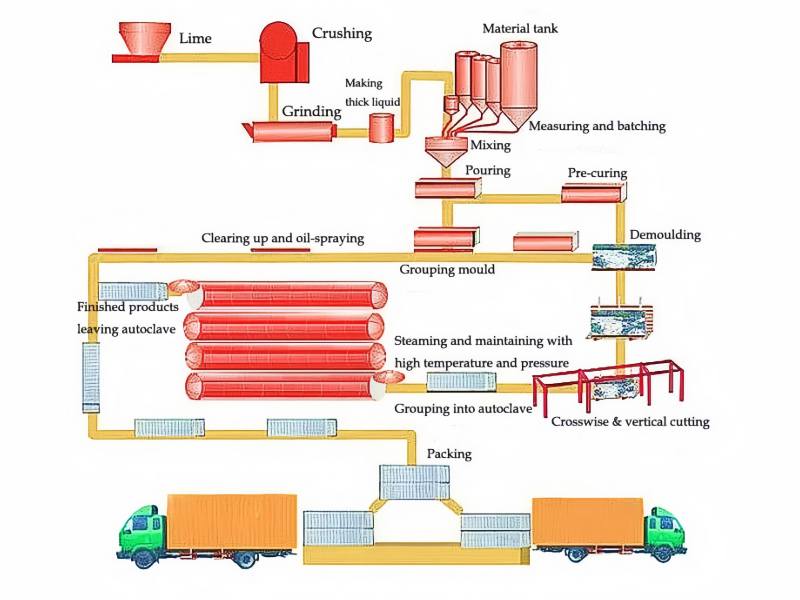

Mini AAC Manufacturing Process

1. Raw material process

The process begins with the treatment of raw materials. Fly ash or sand is transported via conveyor belts to a ball mill for milling. After milling, the resulting slurry is pumped into a slurry storage tank for further use.

2. Dosing and Mixing

Lime and cement are conveyed to dry powder measure scales, where they are accurately measured. The slurry from the storage tank is also pumped to an automatic scale. These measured materials are then mixed together in a mixer and poured into molds.

2. Moulding, Rinsing, and Pre-curing

The mixed slurry is poured into molds, which are then placed in a curing room maintained at 50 – 70 °C. After 2 – 3 hours of pre – curing, the blocks start to solidify.

3. Demoulding and Cutting

A reversal crane is used to carry the mold and block to a cutting cart for demoulding. The cutting cart then transports the block to a series of cutting machines, including level cutting, vertical cutting, and two – side cutting machines. The top waste material is also removed at this stage.

4. Autoclaving

The cut semi-products are grouped in front of the autoclave. A hoisting machine or dragger then moves the steam trolleys loaded with the blocks into the autoclave for steam treatment, which typically takes 10 – 12 hours. This process significantly enhances the strength and durability of the AAC blocks.

5. Packing and loading

Once the blocks are out of the autoclave, a separating machine is used to separate them layer by layer. The finished products are then clamped by a carry hanger and placed on a packaging line on wooden pallets. Finally, forklifts transport the packaged products to the storage yard for stacking according to specifications.

Main Equipment Used in Mini AAC Plant

Ball Mill: Essential for milling fly ash or sand to the required fineness.

Slurry Mixer: Ensures the homogeneous mixing of various raw materials.

AAC Moulds: Where the slurry is poured to take the shape of the blocks.

Cutting Machines: These include level cutting, vertical cutting, and two – side cutting machines, which accurately shape the blocks.

Autoclave: The heart of the process, where high – temperature steam treatment occurs.

Ferry Cart: Facilitates the movement of materials and semi – products within the plant.

Advantages of Mini AAC Block Plant

Less Investment: As mentioned earlier, it requires fewer equipment, a smaller factory area, and less power supply and human resources compared to larger – scale plants. This significantly reduces the initial investment and ongoing operational costs.

Easy Management: The automatic mini AAC plant is user – friendly, easy to operate, manage, and maintain. The adoption of an automatic batching system improves the efficiency and accuracy of material feeding, which is crucial for maintaining the quality of AAC blocks.

Upgraded Technology: Despite its small scale, the manufacturing process adheres to the same high standards as larger – scale plants. This ensures that the AAC blocks produced are of the highest quality, with excellent thermal insulation, fire – resistance, and lightweight properties.

Environmental Friendly: The raw materials used in AAC production are eco – friendly, and the end – product is also sustainable. Moreover, due to its lower production capacity compared to medium and large AAC plants, the carbon footprint of a mini AAC plant is smaller.

Services You Can Get from Us

Customized AAC Block Plant Process and Layout Design:

Our experienced engineers will design a production process and plant layout that maximizes efficiency and productivity while minimizing costs.

AAC Block Machines Manufacturing and Supplying:

We provide high-quality AAC block machines.

Engineering Construction, Equipment Installation, Personnel Training:

We offer turnkey solutions that include engineering construction, equipment installation, and comprehensive personnel training. Our team will ensure that your plant is up and running smoothly in no time.

Trial production of whole AAC plant:

Before handing over the factory to you, we will conduct a trial production of the production line equipment to ensure that everything is running normally.

Tips for the Layout of Mini/Small AAC Block Plant

- The raw material yard is located near the road to reduce repeated handling.

- An I-shaped layout is adopted to ensure one-way movement of mold carts.

- Parallel autoclaves share a single boiler to reduce piping.

- The stockpiling and loading/unloading areas are located on the same side, with a forklift turning radius of ≤5 meters.

- A 10m x 20m area is reserved for the second phase of expansion—adding two autoclaves to double production capacity.

Why Choose Us?

Customization: We offer customized Mini AAC Plant process and layout design. Our team of experts works closely with our clients to ensure the plant is tailored to their specific production needs, site conditions, and budget constraints.

High-quality Machinery: We are a leading manufacturer and supplier of Mini AAC Plant. All our equipment is manufactured to the highest standards, ensuring low failure rates and low maintenance costs. This results in minimal operating costs and high returns for our clients.

Global Certifications: CE, ASME, SONCAP (Export Certification).