160,000 m³/Year AAC Block Plant Exported to Argentina

In April 2024, our company successfully exported a fully automatic 160,000 m³/year AAC block production line to Argentina.

| Country | Argentina |

| Plant Size | Medium AAC Block Production Line |

| Annual Capacity | 160,000 m³/year |

| Production Range | AAC blocks (75–300 mm), optional panels |

| Automation Level | Fully automatic—from batching to packing |

| Project Category | Turnkey AAC plant (design, manufacturing, installation, commissioning) |

The customer is a building materials company based in Córdoba, supplying local construction companies, brick distributors, and residential developers. Before investing in AAC, their main product line included concrete blocks and precast items.

Customer Goals

- Enter Argentina’s growing AAC market

- Reduce labor dependency

- Improve product quality consistency

- Supply multiple provinces with a medium-scale plant

- Produce cost-effective AAC blocks for housing projects

The customer initially compared suppliers from Germany, Turkey, and China. After technical evaluations and online factory inspections, they chose our solution due to high automation, strong cutting precision, fast installation support, and competitive investment cost.

Our Solution- 160,000 m³/Year AAC Block Plant Exported to Argentina

After evaluating the customer’s land size (18,500 m²), electricity cost, local market demand, budget, and long-term expansion plan, our engineering team recommended a 160,000 m³/year AAC production line.

Why This Capacity Is Ideal for Argentina

- Matches regional demand in Córdoba, Santa Fe & Buenos Aires

- Reasonable investment cost: USD 1.2–2.3 million

- Low operational risk compared to large plants

- Easy for newcomers to scale gradually

- Suitable for both local projects and distribution

Customized Design for Argentina

The following local adaptations were included:

1. Block sizes tailored to Argentinian developers

- 10×20×60 cm

- 12.5×20×60 cm

- 20×20×60 cm

- 25×20×60 cm

2. Density classes (AAC 500 / AAC 600)

Suitable for both load-bearing and non-load-bearing walls.

3. Climate-adapted curing system

Argentina has hot summers and mild winters, so we optimized the pre-curing environment and steam system.

4. Spanish-language control interface

To help local operators use the machine more easily.

Key Advantages of AAC Block Plant Exported to Argentina

✓ High Cutting Accuracy

Our advanced cutting machine ensures:

- Accuracy within ±1–1.5 mm

- Smooth surfaces

- Low waste rate (<3%)

- Faster installation on construction sites

This increases competitiveness in Argentina’s cost-sensitive construction industry.

✓ Fully Automatic Operation

Full automation reduces labor needs from 20+ workers (manual production) to 8–10 workers per shift.

Includes:

- Automatic batching

- Automatic pouring

- Automatic demolding & tilting

- Automatic cutting

- Automatic autoclaving

- Automatic packaging

✓ Low Energy Consumption

Designed to reduce fuel usage through:

- Optimized steam recycling

- High-efficiency boiler system

- Intelligent pressure control

This is crucial because industrial gas prices in Argentina fluctuate.

✓ Durable, Long-Life Equipment

All main components:

- Anti-rust coating

- Reinforced steel structure

- High-temperature resistant parts

Guaranteed lifespan: 25–30 years.

✓ Reduced Production Costs

AAC block production cost in Argentina: USD 40–55/m³

Market price: USD 80–110/m³

→ Excellent return on investment.

Main Equipment Used in This AAC Plant

Main Equipment Delivered

- Raw material batching & dosing system

- Ball mill or silo-based batching (depending on raw materials)

- Casting machine & moulds

- Tilting and demolding crane

- Vertical & horizontal cutting machines

- Side plate return system

- 3 × Autoclaves (Φ2.85m × 26m)

- Boiler & steam system

- Automatic packing line

- Siemens PLC electrical control system

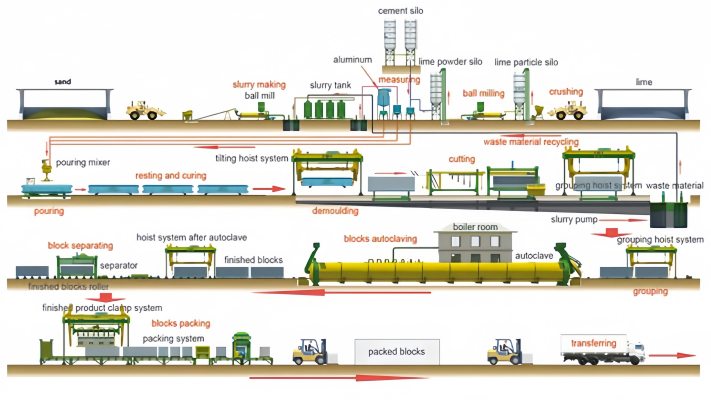

Complete Production Process

- Raw material storage & batching

- Slurry mixing

- Pouring into molds

- Pre-curing

- Demolding & tilting

- Vertical cutting

- Horizontal cutting

- Autoclave curing

- Separating & packing

- Storage & delivery

The entire production flow is organized for maximum efficiency.

Service Workflow — From Inquiry to Plant Startup

January 2024 — Initial Discussion

- Capacity planning

- Investment estimation

- Local market analysis

February 2024 — Customized Design

- Factory layout

- Equipment list

- Utility consumption list

- Price quotation

March 2024 — Manufacturing & Testing

- Cutting machine precision testing

- Autoclave pressure test

- Quality inspections

April 2024 — Shipment to Argentina

- 40 containers shipped to Port of Buenos Aires

- Full logistics tracking & documentation

May–June 2024 — Installation in Córdoba

- 5 engineers on-site

- Mechanical installation

- Electrical wiring

- Pipeline & boiler setup

July 2024 — Commissioning & Training

- Operator training in Spanish

- Quality control guidance

- Production optimization

August 2024 — Formal Production Start

The AAC Block Plant Exported to Argentina reached 98% designed capacity within the first month.

8. Results After Commissioning

- Daily Output: 480–530 m³

- Breakage Rate: < 2.7%

- Cutting Tolerance: ±1.2 mm

- Energy Consumption: 15% lower than projected

- Market Expansion: Able to supply Córdoba, Santa Fe, Buenos Aires

- ROI: Expected in 2.5–3 years

Post-Commissioning Results

Daily Output: 480–530 m³

Breakage Rate: < 2.7%

Cutting Tolerance: ±1.2 mm

Energy Consumption: 15% lower than projected

Market Expansion: Able to supply Córdoba, Santa Fe, Buenos Aires

ROI: Expected in 2.5–3 years

What Our Client Says?

Your engineers supported us throughout the installation and training process, making startup much easier than expected.

We are very satisfied with the performance and reliability of the entire production line.”

— Director, EcoConstrucción S.A., Córdoba, Argentina

Why Choose Us?

✔ 20+ years of AAC manufacturing experience

Trusted by global clients across 80+ countries.

✔ High automation & low labor requirement

Perfect for markets with growing labor costs.

✔ Strong cutting precision

Ensures high-quality AAC blocks.

✔ Full turnkey service

Design → manufacturing → installation → commissioning → training.

✔ Competitive pricing

Higher value and lower investment compared to European suppliers.

✔ Reliable long-term support

Fast spare parts supply and online technical guidance.

Start Your AAC Block Manufacturing Plant?

Whether you are planning a small, medium, or large-scale AAC factory, we can provide:

- Feasibility report

- Plant design

- Equipment configuration

- Cost analysis

- Turnkey delivery and installation

- Long-term technical support

Contact us to get a complete proposal for your AAC block plant project.