200,000 m³/year AAC Block Plant Exported to Turkey Successfully

Turkey has seen a rapid rise in demand for lightweight, energy-efficient, and environmentally friendly wall materials in recent years. To support the local construction boom and comply with stricter thermal insulation standards, one of Turkey’s leading building material companies chose our 200,000 m³/year Medium-Size AAC Block Production Line.

Why the Turkish Customer Chose a 200,000 m³/year AAC Plant?

Based on Turkey’s construction market, energy-efficiency policies, and raw material availability, a 100,000–200,000 m³/year Medium AAC Plant is the most suitable category.

This production scale offers:

- High economic return

- Stable supply for regional markets (Ankara, Istanbul, Izmir, Bursa, Konya, Gaziantep, etc.)

- Competitive cost per cubic meter

- Quick installation and fast ROI (1–2 years)

Plant Specifications Selected for Turkey

- Plant Type: Medium AAC Plant

- Annual Capacity: 200,000 m³/year

- Investment Range: USD 1.2–2.3 million

- Raw Materials: Fly ash, cement, lime, gypsum, aluminum powder

- Final Products: AAC blocks (600×200×150 mm, 600×200×100 mm), partition panels

Customer Requirements

The Turkish customer had very clear expectations, which helped us design an optimal solution.

Customer’s Main Requirements

- Stable production 200,000 m³/year

- Fully automatic system to reduce labor cost

- Low energy consumption

- High-precision cutting for smooth block surfaces

- Advanced autoclaving technology

- Full installation + training + after-sales support

Customer’s Pain Points

(We designed solutions for all)

- Lack of AAC manufacturing experience

- Concerns about local raw material ratios

- Need for energy-efficient equipment

- Requirement for CE-compliant machinery

- Desire for fast installation and quick ROI

Our engineering team addressed each requirement with a customized plant layout and technology upgrade plan.

Solution We Provided – Complete Turnkey AAC Block Plant Exported to Turkey

We delivered a turnkey solution covering the entire AAC production process.

1. Raw Material Processing System

- Fly ash grinding & storage

- Automatic batching & dosing

- High-precision slurry mixing

2. Cutting System

- Fully automatic vertical + horizontal cutting

- Accuracy up to ±1 mm

- Smooth block surfaces (easy plastering)

- Reduces material waste by 3–5%

3. Autoclave Section (CE Certified)

- Imported valves & safety system

- Uniform pressure distribution

- High steam utilization rate

4. Finished Block Handling System

- Fast automatic grouping

- Palletizing + packaging system

- Reduces labor from 10 workers to 3 workers

5. Full Automation Control

- Siemens PLC

- Smart diagnostics for equipment

- Energy consumption reduced by 12–15%

Advantages of the AAC Production Line Exported to Turkey

1. Built for Turkish Raw Materials (Fly Ash + Sand Mix)

We tested multiple formulas to achieve:

- Higher strength

- Lower density

- Shorter curing time

2. Energy-Saving Design

- Optimized autoclave steam cycle

- Recycled slurry system

- Upgraded air compressor for 8% power savings

3. High Output + Low Operation Cost

Perfect for the Turkish market where labor costs are rising.

4. CE-Compliant Machinery

Required for Turkish and EU markets.

Helps customer export AAC products to neighboring countries.

5. Strong On-Site Service Team

- Installation engineers sent to Turkey

- One-stop training (production, maintenance, QC)

- 24/7 remote technical support

Project Timeline

| Stage | Duration | Details |

|---|---|---|

| Solution Proposal | 7 days | Market analysis + layout + budget |

| Contract & Production | 50–60 days | Manufacturing of full AAC line |

| Shipping to Turkey | 18–25 days | Sea transportation |

| Installation & Commissioning | 35–45 days | On-site assembly + testing |

| Trial Production | 7–10 days | Formula optimization |

| Commercial Production | – | Plant running at full capacity |

Total time from order to full production: 3–4 months

Results After Installation

After commissioning, the customer achieved:

- Full Production Capacity: 200,000 m³/year: Supports large-scale supply across Turkey.

- High-Strength Blocks (Grade ≥ 3.5–4.0 MPa): Passed Turkish standards easily.

- 12–15% Lower Energy Consumption

- 98% Product Qualification Rate:

- Fast ROI (1.5 years projected)

The customer is now planning to expand to a 300,000–350,000 m³/year AAC panel line in the next phase.

What Is an AAC Block Production Line?

An AAC (Autoclaved Aerated Concrete) block manufacturing plant is a complete set of machines used to produce lightweight, thermal-insulating, fire-resistant concrete blocks.

Main Characteristics

- Lightweight (density 500–650 kg/m³)

- Fire-resistant up to 4 hours

- Excellent thermal insulation

- Sound absorption

- Easy to cut and install

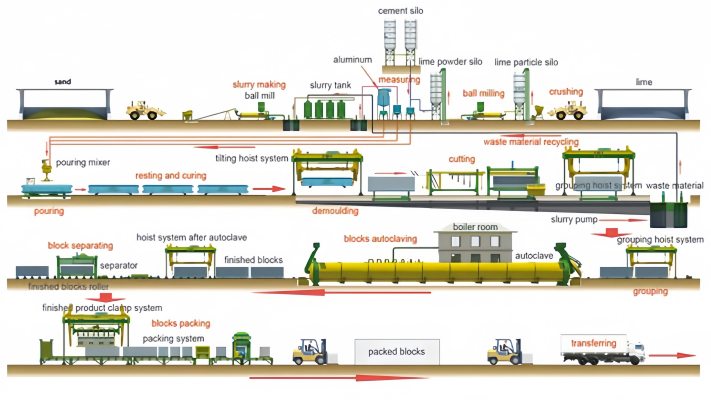

Typical AAC Production Process

- Raw material batching

- Slurry mixing

- Pouring into molds

- Cutting

- Autoclaving

- Packaging

We provide turnkey solutions, from design to installation.

Looking to Build an AAC Block Manufacturing Plant?

We have successfully exported AAC plants to 80+ countries, and Turkey is one of our key markets.

If you are planning to set up a new AAC block factory —whether 30,000 m³/year mini plant or 600,000 m³/year large plant—we can customize the entire solution.