A 250,000 m3/year AAC plant is a fully automated AAC block manufacturing line capable of producing 250,000 cubic meters of AAC blocks annually. This category belongs to large AAC production lines, commonly used by:

- National building material suppliers

- Construction groups

- Real-estate developers manufacturing their own wall materials

- Investors targeting high-volume domestic and export markets

- Government and PPP urban development projects

Typical production outputs:

- AAC blocks (100–300 mm)

- AAC wall panels (optional add-on)

- Reinforced AAC panels (optional)

- Customized density grades

Daily production capacity:

≈ 700–900 m³/day (based on 300 working days)

The 250,000 m³/year capacity ensures stable supply for large-scale construction projects and allows long-term contract manufacturing for clients such as public housing, industrial buildings, high-rise wall partition systems, and green building materials companies.I within 18–30 months.

Price Range of a 250,000 m3/Year AAC Plant

The setup cost of a 250,000 m3/Year AAC Plant ranges from 2,000,000– 3,000,000 USD.

Cost Includes

- Complete production line equipment

- Foundation and layout design

- Installation & commissioning

- Spare parts package

- Training for operation and maintenance

- Technical support and engineering service

Advantages of 250,000 m3/Year AAC Plant

Investors choose this capacity because it provides the best balance of scalability, automation, and cost efficiency. Major benefits include:

1. High Automation for Stable Quality

The line integrates PLC control systems, automated batching, cutting, circulation, and autoclave loading.

Benefits:

- Stable block dimensions

- Less human error

- Lower labor cost per cubic meter

This automation level is critical for meeting government quality standards and international export requirements.

2. Large Output, Lower Unit Production Cost

Because fixed investment is spread over higher yearly output, per-m³ production cost drops by 10–15% compared with 100,000–150,000 m³/year plants.

3. High Profitability for National Markets

This capacity supports:

- Long-term government supply contracts

- Large developers needing stable material supply

- Export to nearby countries

- Economies of scale → higher annual ROI

Most investors achieve ROI within 18–36 months.

4. Flexible Product Range

Customers can produce:

- AAC blocks

- AAC wall panels

- U-blocks

- Tongue-and-groove wall panels

- Reinforced structural panels (optional line extension)

This flexibility opens multiple revenue streams.

5. Lower Labor Requirement vs. Output

Although large, this plant requires only:

- 30–40 workers in total

- 6–10 technicians per shift

Thanks to automation, labor efficiency is significantly improved.

6. Stable Performance and Easy Maintenance

Large-size autoclaves, advanced cutting machines, and well-designed fermentation systems result in:

- Lower maintenance cost

- Higher uptime

- Longer equipment service life (over 15–20 years)

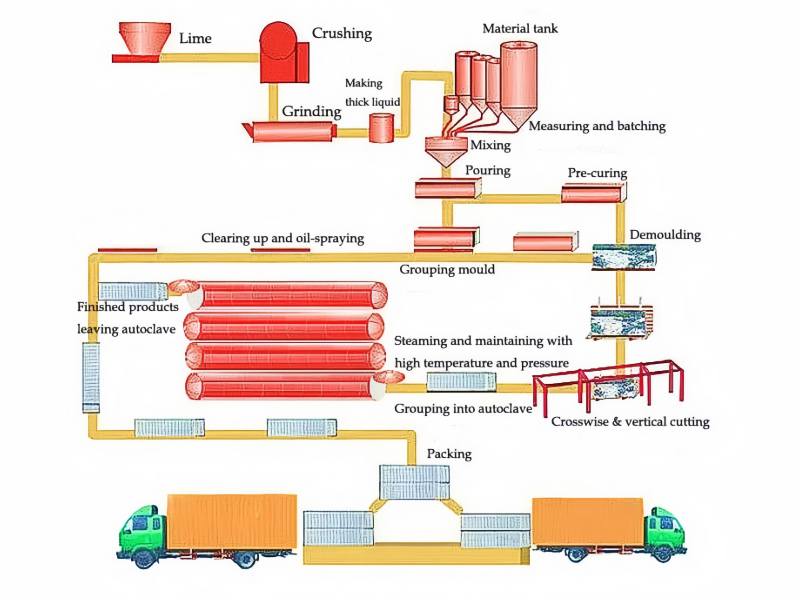

250,000 m3/Year AAC Plant Process

Raw material process → Batching and Mixing → Pouring → Static pre-curing → Cutting → Autoclaving Curing → Finished product Processing

1. Raw Material Processing: Sand is crushed and ground to the desired fineness. Cement, lime, and gypsum are stored in silos, and aluminum powder is mixed with water to form an aluminum slurry.

2. Batching and Mixing: The various raw materials are weighed according to precise proportions and then thoroughly mixed in a mixer to form a uniform slurry.

3. Pouring: The mixed slurry is poured into steel molds. The size and shape of the molds can be designed to meet the desired block specifications.

4. Static Pre-curing: The molds containing the slurry are transported to a pre-curing area where the slurry gradually hardens under suitable temperature and humidity conditions to achieve initial strength. This process typically takes several hours.

5. Cutting: After the slurry is pre-cured, it is cut into the desired size and shape using high-precision cutting equipment like steel wire or blades.

6. Autoclave Curing: Blocks are placed in an autoclave and cured for several hours at temperatures of 175-200°C and pressures of 10-15 bar, significantly enhancing the blocks’ strength and durability.

7. Finished Product Processing: After autoclave curing, the blocks are removed from the autoclave and transported to a storage area. After inspection and packaging, they are ready for shipment.

Raw Materials of AAC block

- Cement (Portland Cement): Acts as a primary binder, providing strength and durability to the blocks. Typically, 43 or 53-grade OPC is used.

- Fly Ash or Sand: Serves as the main siliceous material. Fly ash, a byproduct of coal-fired power plants, is an eco-friendly alternative to sand, providing the necessary silica content.

- Lime: A key calcareous material that reacts with other components to form the binding matrix and contributes to the chemical reactions during production.

- Gypsum: Added in small quantities to regulate the setting time and improve the workability of the mix.

- Aluminum Powder or Paste: Functions as a foaming agent. It reacts with lime and water to produce hydrogen gas, creating the characteristic porous, lightweight structure.

- Water: Essential for the hydration of cement and lime, and to facilitate the chemical reactions necessary for the setting and hardening of the blocks.

These materials are carefully proportioned and mixed to form a slurry, which is then cast, pre-cured, cut, and finally autoclaved to produce the finished AAC blocks.

Main Equipment in 250,000 m3/Year AAC Plant

1. Jaw Crusher

Function: Crushes large lumps of raw materials such as limestone and gypsum into 50-150 mm pieces, facilitating subsequent fine grinding. It is a key piece of equipment for raw material pretreatment.

Structure: A fixed jaw plate and a movable jaw plate form a deep-chamber crushing chamber lined with impact-resistant, replaceable high-manganese steel tooth plates.

Capacity Range: Common models range from 100 to 500 t/h. The motor and main unit are integrated on a steel frame base, occupying only 4-6 m² of floor space.

2. Ball Mill

Function: Grinds crushed lime, sand, or fly ash into a fine powder with a mesh size of 80-400 (0.2-0.045 mm) to enhance reactivity.

Structure: Horizontal cylinder+wear-resistant liner+steel ball media. It driven by a motor, reducer, and large gear.

Key Parameters: Cylinder diameter 1.2-2.4 m, ball load 5-30 t, power 55-800 kW.

3. Batching System

Function: Accurately weighs cement, lime, fly ash, aluminum powder, and water according to the recipe, with an error of ≤ ±0.5%. Equipped with multiple silos, metering, and conveying equipment.

Module components: Electronic scale, screw feeder, pneumatic butterfly valve, PLC touch screen; one-touch recipe call, batching completed within 30 seconds.

4. Mixing & Casting Machine

Function: Rapidly mixes weighed dry materials with water and aluminum powder into a fluid slurry, which is then poured into a mold for foaming.

Features: Twin-shaft forced mixing completes one batch in 60-90 seconds; hydraulically tilts 90° for drip-free pouring.

Key Parameters: Effective volume 2-4 m³, motor power 37-55 kW, removable mixing blades, wear life ≥ 30,000 cycles.

5. Tilting Cutter

Function: Cuts pre-cured billets into desired specifications with an accuracy of ±1 mm. Offcuts are recycled online.

Structure: Three sets of longitudinal, transverse, and horizontal steel wire frames; servo motors synchronize lifting and lowering, automatically compensating for wire wear.

Capacity: Cutting cycle ≤ 5 minutes/die; can cut 75-300 mm thickness, 600 mm standard length, or 1200 mm slabs.

6. Autoclave

Function: High-temperature, high-pressure steam curing allows the green body to complete the hydrothermal synthesis reaction within 8 hours, increasing its strength by 5-8 times.

Specifications: Φ2.68×32 m or Φ2.85×38 m; design pressure 1.6 MPa, operating temperature 200°C; equipped with safety interlock and automatic blowdown.

Configuration: Each medium-sized line is equipped with 4-8 units, which can be connected in series or parallel. Energy-saving models include a waste heat recovery interface.

7. PLC Control Room

Function: Serves as the control center for the entire production line, offering features such as recipe management, parameter adjustment, process monitoring, energy consumption analysis, fault alarms, and remote app viewing.

Hardware: Reserved OPC UA interface for integration with the factory’s MES/ERP system.

8. Waste Gas Heat Recovery System

Principle: Autoclave exhaust gas at 160°C is preheated to 90°C via a heat exchanger, saving 8–12% of natural gas annually.

Configuration: Plate heat exchanger+circulation pump+automatic temperature control valve.

Technical Parameters of a 250,000 m3/Year AAC Plant

| Item | Specification |

|---|---|

| Annual capacity | 250,000 m³ |

| Daily output | 700–900 m³ |

| Raw material | Sand/fly ash, cement, lime, gypsum |

| Density grades | 400 / 500 / 600 / 700 kg/m³ |

| Autoclaves | 10–14 units (depending on length) |

| Autoclave pressure | 1.2–1.4 MPa |

| Cutting accuracy | ±1–2 mm |

| Cycle time per mold | 12–16 hours |

| Automation level | High |

| Workers per shift | 30–40 |

What Is An AAC Block?

Autoclaved aerated concrete (AAC) blocks are a lightweight, porous, high-strength new building material.

The unique internal pore structure provides lightweight, high strength, thermal insulation, fire resistance, and sound insulation.

It is an ideal choice for achieving energy-saving and structural safety in buildings.

Application of AAC Block

Civil Buildings: Used in internal and external walls, floor slabs, roof slabs, etc. of residential buildings to reduce building weight and improve seismic performance.

Commercial Buildings: Suitable for non-load-bearing walls of shopping malls, hotels, office buildings, etc., with good thermal insulation and sound insulation effects to enhance building comfort.

Industrial Buildings: Served as wall and partition materials for factories and warehouses, meeting the special requirements of industrial production for building materials.

Special Buildings: Widely applied in hospitals, schools, gymnasiums and other places due to their excellent fire resistance and environmental protection properties.

250,000 m3/Year AAC Plant Exported to Singapore

A Singapore-based construction material group required a high-capacity AAC plant to support:

- Rapid public housing development

- Lightweight wall solutions for high-rise buildings

- Environmentally friendly construction materials

They needed stable supply, strict quality standards, and automated operation.

Project Details:

- Capacity: 250,000 m³/year

- Raw material: Sand-based AAC

- Autoclaves: 12 × 32 m

- Land area: 25,000–30,000 m²

- Installation period: 4–6 months

Why Choose Us as Your AAC Block Plant Supplier?

Investors choose us because we deliver quality, reliability, and complete technical support.

1. 20+ Years of AAC Engineering Experience

We have installed AAC plants in:

- Southeast Asia

- Middle East

- Africa

- Eastern Europe

- Latin America

Our technical team has handled 30,000 m³ to 600,000 m³ AAC lines worldwide.

2. Complete Turnkey Service

We provide:

- Project consulting

- Layout design

- Raw material testing

- Equipment manufacturing

- Global shipping

- Installation & commissioning

- Formula optimization

- Long-term technical support

3. Advanced Cutting Technology

Smooth cutting, low waste, and precise dimensions give your blocks strong market competitiveness.

4. Strong Autoclave Manufacturing Capability

Our autoclaves feature:

- seamless welding

- high-pressure tests

- optimized steam circulation

Ensuring long lifetime (15–20 years).

5. Lower Operating Costs

Efficient machinery allows you to reduce:

- energy consumption

- labor cost

- material waste

- maintenance cost

6. Fast ROI & High Profitability

Typical payback period: 18–30 months

Profit margin per m³: USD 12–22 (varies by region)

Services We Offer

- Project Planning & Design

Provide overall planning and detailed design schemes for AAC block plants based on client needs and actual conditions, including process design, equipment layout, and civil engineering design. - Equipment Supply & Installation

Supply full sets of AAC production line equipment, and undertake installation and commissioning to ensure normal operation, meeting designed capacity and product quality standards. - Technical Training

Offer professional training for operators, technicians, and managers covering production processes, equipment operation, maintenance, and quality management. - After-Sales Service

Establish a sound after-sales system providing daily maintenance guidance, fault troubleshooting, and spare parts supply to ensure continuous stable production. - Technical Support & Upgrades

Provide ongoing technical support and offer equipment upgrading/technical transformation solutions based on client needs and industry trends to improve efficiency and quality. - EPC General Contracting

One-stop EPC services from design, equipment procurement, civil construction, installation, and training to trial production for a hassle-free experience.

Other Hot-sale Block Manufacturing Plant

| Annual Production | Price (USD) | Core Configuration |

|---|---|---|

| 100,000 m³ | 1.5–1.9 M | Air-turning cutting, 3×31 m autoclaves |

| 150,000 m³ | 2.1–2.6 M | Robotic palletizing, 4×31 m autoclaves |

| 200,000 m³ | 2.8–3.5 M | Six-sided cutting, 4×37 m autoclaves |

| 300,000 m³ | 4.0–4.8 M | Dual cutting lines, 6×37 m autoclaves |

| 400,000 m³ | 5.5–6.5 M | Fully automatic air-turning, 8×37 m and above autoclaves |