250,000 CBM/year AAC Block Plant Exported to Romania

As one of the world’s leading AAC block manufacturing plants with over 20 years of experience and exports to more than 80 countries, we are proud to announce the successful delivery of our large-scale AAC block plant to Romania. This plant is designed to meet the growing demand for energy-efficient, lightweight, and durable construction materials across the Romanian market.

- Plant Type: Large AAC Production Line

- Annual Capacity: 250,000 CBM/year

- Setup Cost Range: 2,000,000 – 3,000,000 USD

- Target Market: National construction projects, large-scale building contractors

- Location: Romania

This production line is tailored to Romania’s increasing demand for sustainable building materials, including residential and commercial construction projects. With this plant, our Romanian clients can efficiently produce high-quality AAC blocks locally, reducing reliance on imported materials and cutting costs.

What is an AAC Block Plant?

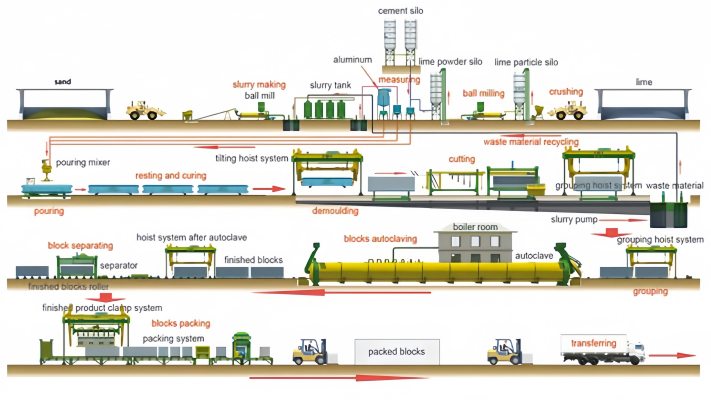

An AAC (Autoclaved Aerated Concrete) block plant is a fully integrated system designed to manufacture lightweight, fire-resistant, and energy-efficient concrete blocks. Key components of a modern AAC plant include:

- Raw material mixing system

- Casting and molding line

- Autoclave curing system

- Cutting and packaging equipment

The final AAC blocks are:

- Lightweight, reducing structural load

- Thermally insulating, lowering energy costs

- Fireproof and environmentally friendly

- Easy to install, reducing construction time

Features and Advantages of AAC Block Plant to Romania

Our AAC Block Plant to Romania is equipped with state-of-the-art technology, ensuring high efficiency, reliability, and profitability. Key advantages include:

- High Production Capacity – With an annual output of 250,000 CBM, the plant can meet nationwide construction demands.

- Energy Efficiency – Optimized autoclaving and mixing systems reduce energy consumption.

- Consistent Quality – Automated systems ensure uniform block density and size.

- Advanced Automation – PLC control and monitoring for seamless operation with minimal labor.

- Low Operational Costs – High yield with low raw material and energy costs.

- Eco-Friendly Production – Uses sustainable raw materials and reduces CO₂ emissions.

- Scalable Solutions – Can expand production capacity as the market grows.

Why Romanian Builders Choose Our AAC Plant?

Customers in Romania are increasingly focused on cost-effective and sustainable construction solutions. Our AAC plant addresses common challenges such as:

- High material costs: Producing AAC blocks locally reduces import dependency.

- Project delays: Automated production ensures timely delivery of high-quality blocks.

- Labor shortage: Advanced machinery reduces labor intensity and operational risk.

- Energy efficiency: AAC blocks improve insulation in buildings, meeting EU standards.

By installing our AAC production line, Romanian construction companies gain a competitive advantage in the local market.

Romania Case Success: From Delivery to Operation

The AAC Block Plant to Romania was delivered on schedule, with our team providing:

- On-site installation guidance

- Staff training for operation and maintenance

- Customized production workflow for Romanian market needs

Since its launch, the plant has successfully started producing high-quality AAC blocks that comply with European construction standards, enhancing building efficiency and safety.

Complete Production Process

- Sand processing & grinding

- Slurry mixing

- Mold casting

- Pre-curing

- Tilting & demolding

- Horizontal & vertical precision cutting

- Grouping & autoclaving

- Steam curing cycle

- Final inspection

- Automated packaging & palletizing

Our engineers ensured stable production from day one.

FAQ: Romanian Customers’ Top Questions

Q1: What is the average production cost per cubic meter?

A: Depending on raw material cost and plant utilization, the production cost ranges from 35–45 USD per CBM.

Q2: What is the expected ROI for a large AAC plant in Romania?

A: Typically, ROI is achievable within 2–3 years, considering local demand and construction growth.

Q3: Can the plant produce blocks of different sizes?

A: Yes, our line can produce custom-sized AAC blocks based on client specifications.

Q4: How energy-efficient is the plant?

A: Our advanced autoclaves and optimized workflows reduce energy consumption by up to 20% compared to traditional systems.

Partner with a Trusted AAC Block Manufacturer

Whether you need:

- A 30,000–600,000 m³/year AAC block manufacturing plant

- Customized block densities

- Fully automatic or semi-automatic configurations

- Turnkey engineering support

- Cost estimation for a new AAC factory

We can provide a complete solution.

👉 Contact us today for a free feasibility report and quotation.

Our engineering team will design the best AAC block manufacturing solution for your market.