What Exactly is an AAC Block Mini Plant?

An AAC block mini plant is a compact-scale autoclaved aerated concrete block production line designed for annual outputs between 30,000 to 100,000 cubic meters. Unlike massive industrial setups, mini plants offer:

- Lower capital entry: 70-80% less investment than standard plants

- Faster installation: 3-4 months vs 8-12 months

- Flexible production: Easy adjustment to local market demands

- Simplified operation: Perfect for first-time AAC block manufacturers

Our mini plant configuration includes fully automated batching, mixing, casting, cutting, and autoclave curing systems—scaled intelligently for emerging markets and regional suppliers.

AAC Block Mini Plant Price: Real Cost Breakdown

Based on our recent 50+ installations across emerging markets, the realistic AAC mini plant setup cost reicht von $100,000 to $1,000,000 USD (Ex-Works China). This broad range reflects real customization needs:

Complete Cost Structure Analysis

| Cost Component | Budget Range | What It Includes |

|---|---|---|

| Core Equipment | $65,000 – $550,000 | Mixer, moulds, cutting machine, autoclaves (2-4 sets), boilers |

| Installation & Commissioning | $15,000 – $120,000 | Technical supervision, local labor coordination, testing |

| Engineering & Design | $8,000 – $80,000 | Plant layout, utility planning, process flow optimization |

| Spare Parts & Training | $12,000 – $50,000 | 2-year critical spares, operator training, maintenance manuals |

Critical insight: The $100K entry-level configuration uses manual cutting and single autoclave, ideal for testing markets. The $1M premium setup features semi-automatic cutting and 4 autoclaves, delivering 100,000 CBM/year with 15+ years lifespan.

Hidden Factors That Dramatically Change Your AAC Plant Investment

When comparing aac block Anlage Kosten quotes, watch for these variables that explain AAC Block Mini Plant Price differences:

1. Automatisierungsgrad

- Manual cutting: Reduces cost by $180K but limits precision

- Halbautomatisch: Best ROI for mini plants (+$220K, doubles output quality)

- Vollautomatisch: Overkill for mini scale, adds $400K+ unnecessarily

2. Autoclave Quantity & Size

Each additional 2m × 31m autoclave adds $85,000 but increases daily output by 30%. For 50,000 CBM/year target, 2 autoclaves are optimal; for 100,000 CBM, you need 4.

3. Anpassung der Rohstoffe

If your local sand requires grinding or lime needs special handling, add $45,000-$120K for preprocessing equipment. We provide free material testing to calculate this accurately.

4. Utility Integration

- Boiler capacity: 2-ton vs 4-ton difference = $35,000

- Dust collection: Environmental compliance adds $25,000-$60,000

- Water recycling: Recommended for water-scarce regions (+$18,000)

5. After-Sales Support Package

Basic package: Remote guidance. Premium package: On-site engineer for 30 days (+$35K). For new investors, we strongly recommend the premium option—it prevents costly operational mistakes.

Mini vs. Medium vs. Large: Which AAC Plant Size Fits You?

| Plant Type | Capacity (CBM/Year) | Setup Cost | Amortisationszeit | Ideal For |

|---|---|---|---|---|

| Mini-AAC-Anlage | 30,000 - 100,000 | $100K – $1M | 1.5 – 3 years | Local builders, new market entry, limited capital |

| Mittlere AAC-Anlage | 100,000 - 200,000 | $1.2M – $2.3M | 2.5 – 4 years | Regional suppliers, established construction companies |

| Große AAC-Anlage | 200,000 – 600,000+ | $2M – $3M+ | 4 - 6 Jahre | National distributors, large construction groups |

Why 68% of our clients start with mini plants: Lower financial risk, faster market validation, and easier permit approval. Many later upgrade by adding autoclaves rather than building new facilities.

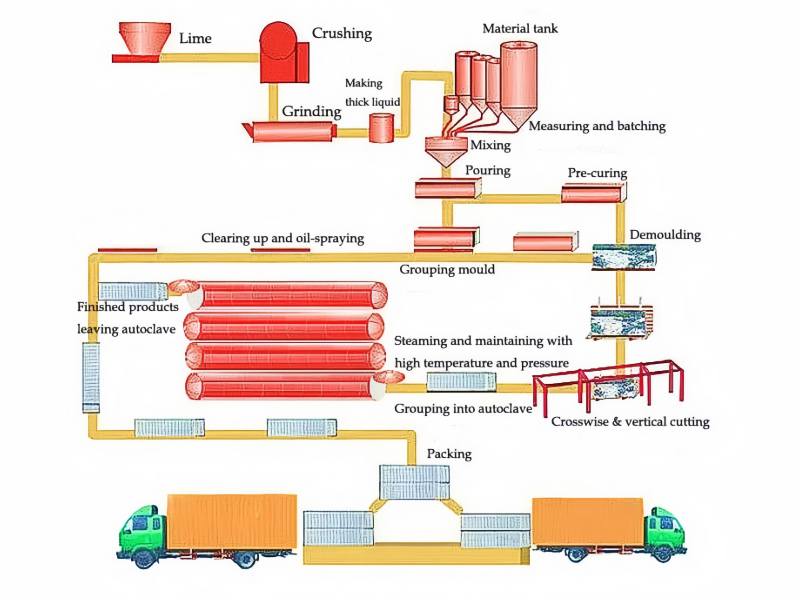

AAC Small Plant Production Process Flow

A kleine AAC-Blockanlage follows a complete and precise production process to ensure each block meets quality standards for strength, density, and insulation.

Below is the simplified AAC block manufacturing process flow — from raw material preparation to final packaging:

1️⃣ Raw Material Preparation & Batching

Cement, lime, fly ash (or sand), gypsum, and aluminum powder are weighed and mixed in exact proportions according to the formula.

2️⃣ Slurry Mixing & Pouring

The mixed slurry is poured into molds. During this stage, chemical reactions between lime and aluminum powder release hydrogen gas, creating a porous structure.

3️⃣ Pre-curing

The green cake expands and gains initial strength in a pre-curing chamber (40–50 ℃) for 2–3 hours.

4️⃣ Demolding & Cutting

The semi-solid cake is removed from the mold and sent to a cutting machine for horizontal and vertical precision cutting, forming uniform blocks.

5️⃣ Autoclaving (High-Pressure Steam Curing)

Cut blocks are placed into autoclaves and cured under high temperature and pressure (180–200 ℃, 12–16 bar) for 10–12 hours. This process gives AAC blocks their final strength and stability.

6️⃣ Packing & Storage

After curing, blocks are inspected, stacked, and packed for transportation or sale.

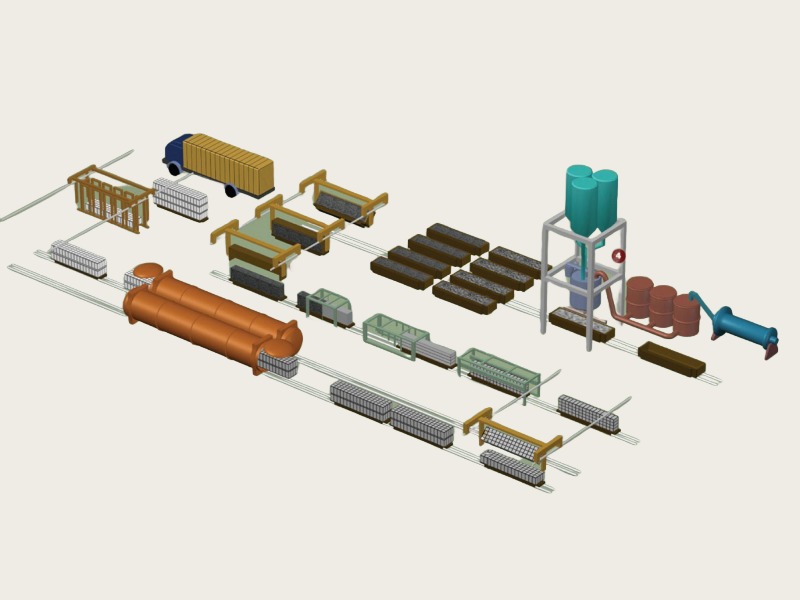

What’s Included in a Small AAC Block Plant?

Even a small plant includes all the essential equipment required for continuous production:

- Raw material batching & mixing system

- Mold casting and pre-curing section

- Cutting machine (horizontal & vertical cutting)

- Autoclave system for steam curing

- Block handling and packaging system

Our company provides a turnkey solution — from layout design and equipment manufacturing to installation, training, and after-sales support — helping you start production quickly and safely.

Recommended Equipment List for Small AAC Block Plant

Below is a recommended equipment configuration for a 30,000–100,000 m³/year small AAC plant, designed to balance cost efficiency and production quality.

| Section | Hauptausrüstung | Function / Description |

|---|---|---|

| Vorbereitung des Rohmaterials | Ball mill / fly ash silo / lime silo / slurry tank | Grinding and storage of raw materials |

| Batching & Mixing System | Automatic weighing & mixing system | Ensures accurate proportion of raw materials |

| Casting Section | Moulds and casting crane | Pouring slurry into molds for block formation |

| Pre-curing System | Pre-curing chamber with heating system | Allows block expansion and initial strength |

| Cutting Section | Vertical & horizontal cutting machine | High-precision cutting for uniform block size |

| Autoklaviersystem | Autoclaves (steam curing tanks) | Strengthening and solidifying AAC blocks |

| Handling & Packing | De-moulding crane, stacking machine, packing system | Automated handling and final packaging |

| Electrical & Control System | PLC control cabinet | Centralized control and operation monitoring |

💡 Tip: For small plants, semi-automatic systems are most cost-effective — they reduce labor costs without the high investment of full automation.

50,000 m³/year AAC Small Plant in Kenya

In 2024, our company helped a construction materials firm in Kenya set up a 50,000 m³/year AAC small plant.

Within four months, the factory started stable production.

The client reported:

- 25% reduction in labor cost thanks to automation,

- Rapid local market growth due to rising demand for lightweight blocks,

- ROI (Return on Investment) achieved in under two years.

Why Our AAC Mini Plant Outperforms Competitors at Same Price Point

As a dedicated AAC block machine manufacturer (not a trading company), we control every cost-quality lever:

Manufacturing Transparency Advantage

- In-house production: Our foundry and machining center cuts middleman markup by 22-28%

- ISO 9001 certified: Every autoclave undergoes X-ray weld inspection (competitors often skip this)

- Motor & PLC brands: Siemens, ABB—no cheap substitutions after contract signing

Proven ROI for New Investors

Our 2024 Nigeria client’s mini plant (60,000 CBM/year capacity) achieved:

- Gesamtinvestition: $380,000 USD

- Production cost: $45/CBM (local raw materials)

- Selling price: $85/CBM

- Gross margin: $40/CBM × 60,000 = $2.4M annual revenue

- Payback: 23 months (including 3-month construction)

Risk-Free Guarantee

- Performance warranty: We guarantee output capacity and block strength in writing

- Installation success: No payment release until successful test production

- Ersatzteile: 48-hour shipping guarantee for 5 years

About Our Company

With 150+ AAC block production lines installed across 80+ countries, we specialize in helping new investors enter the market with confidence. Our engineering team provides end-to-end support from raw material testing to final product certification. Unlike general machinery suppliers, we focus exclusively on Technologie der Unterstützten Kommunikation, ensuring you get the deepest expertise at every project stage.

📞 Ready to Start Your AAC Block Small Plant?

Whether you want a 30,000 m³/year mini plant or a 100,000 m³/year small plant, our engineering team provides:

- Free project consultation & cost estimation

- Customized plant layout design

- On-site installation and training

📩 Kontakt today to get your AAC Block Small Plant Cost quotation and start your lightweight block business confidently with a reliable partner.

FAQ

The absolute minimum for a functional small scale aac plant is $100,000 USD for a 30,000 CBM/year manual setup. However, we recommend $280,000-$450,000 for semi-automatic configuration to ensure competitive product quality.

Yes, our aac block Anlage Kosten is all-inclusive: equipment, installation supervision, commissioning, and 15-day on-site operator training. No hidden fees.

Absolutely. Our modular design allows adding 1-2 autoclaves and upgrading the cutting system without replacing core equipment. Most clients scale from 50K to 100K CBM within 3 years.

We provide documented equipment valuation for bank loans and have partnerships with China Exim Bank for eligible projects. Many clients secure 60-70% financing using our technical documentation.

Unsere wichtigsten Geräte (Autoklaven, Mischer, Schneidemaschinen) haben eine Lebensdauer von 15-20 Jahre - dank hochwertigem Stahl (Q345R für Autoklaven) und präziser Fertigung. Wir bieten außerdem eine 5-Jahres-Garantie auf die wichtigsten Komponenten.