150,000 m³/Year AAC Block Machine in Netherlands

In April 2025, our company successfully exported and installed a 150,000 m³/year AAC Block Machine and Production Line to a customer in Netherlands.

Exported To: Rotterdam, Netherlands

Installation Period: May–July 2025

Production Line Capacity: 150,000 CBM/Year (Medium AAC Plant)

Plant Size Category: 100,000–200,000 CBM/year

Recommended For: Regional supply + medium-large project demand

In early September 2024, a Dutch construction materials company contacted us for a complete AAC production solution. Their goal was to diversify their product line, reduce material weight for multi-story buildings, and comply with stricter national energy regulations.

After several technical meetings, layout optimization sessions, and cost analysis reports, the client confirmed that our 150,000 CBM/Year Medium AAC Block Plant was the ideal solution.

Customer Background

The client is a well-established construction materials supplier headquartered in Rotterdam, supplying masonry products to contractors, prefab builders, and green building developers.

Customer’s Key Challenges Before Contacting Us:

- Traditional concrete blocks were too heavy for certain building applications.

- The company wanted to enter the energy-efficient material market.

- Labor costs in the Netherlands are high, requiring fully automated equipment.

- They needed a plant that could meet Dutch insulation requirements.

- The previous small factory was unable to meet growing demand from Belgium and Luxembourg.

Their Goals:

- Produce AAC blocks locally

- Reduce dependence on imports

- Lower production cost

- Expand their brand in Benelux

- Build a compliant plant with EU standards

After reviewing their needs, our engineering team recommended a medium-scale AAC block machine line with fully automated controls to reduce labor reliance.

Why We Recommended a 150,000 CBM/Year AAC Block Plant?

✔ Fits the Netherlands’ Market Size

A medium-capacity line ensures steady supply without overshooting local demand.

✔ High Automation for High Labor Costs

The Netherlands has some of the highest labor expenses in Europe.

SIEMENS PLC + automatic cutting + stacking systems reduce manpower requirements significantly.

✔ EU Certification Requirements

We provided CE-compliant electrical components, low-noise systems, and dust-controlled mixing equipment to meet Dutch regulations.

✔ Flexibility to Produce Multiple Block Sizes

AAC blocks for the Netherlands often require customized dimensions such as:

- 600 × 250 × 100 mm

- 600 × 300 × 150 mm

- Thermal insulation blocks of 75 mm

All supported by our cutting machine.

✔ Easy Future Expansion

The plant layout supports upgrading to 200,000–250,000 CBM/year without major reconstruction.

Key Advantages of AAC Block Machine in Netherlands

1. Fully Automated Production Line

Reduces manual labor by 40–60%.

Essential in a country with extremely high labor costs.

2. High-Precision Cutting for EU Market Requirements

AAC block tolerance accuracy ≤ 1 mm, suitable for Dutch thin-joint mortar construction.

3. Energy-Saving Autoclave System

The autoclaves use optimized steam circulation to reduce fuel consumption by 8–12%.

4. Low Noise & Low Dust Mixing System

Meets strict Dutch environmental laws (Arbowet Regulations).

5. Smart Control System (SIEMENS + Remote Monitoring)

Supports Dutch, English, and German interfaces.

Allows remote diagnostics from our engineers in China.

6. High Return on Investment (ROI)

With local AAC demand increasing, the estimated ROI is 1.5–2.3 years.

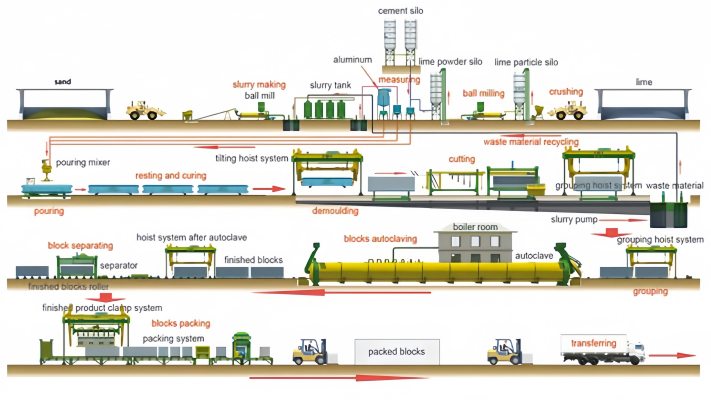

Complete Production Process

- Sand processing & grinding

- Slurry mixing

- Mold casting

- Precurado

- Tilting & demolding

- Horizontal & vertical precision cutting

- Grouping & autoclaving

- Steam curing cycle

- Final inspection

- Automated packaging & palletizing

Our engineers ensured stable production from day one.

Main Equipment List

- Trituradora de mandíbulas

- Molino de bolas

- Slurry and powder batching system

- Aluminum dosing system

- Vertedora

- Pre-curing chamber

- Tilting crane

- Universal AAC cutting machine

- Autoclaves

- Steam boiler system

- Packing machine

Complete Service Workflow – From Inquiry to Commissioning

1. Initial Inquiry – September 2024

Client contacted us through our website.

2. Technical Consultation

We provided layout drawings, raw material analysis, and energy consumption estimates.

3. Factory Visit (Online & On-site)

Due to travel limitations, the client joined a live video tour.

Later, they visited our manufacturing base in December 2024.

4. Contract Signing – January 2025

A complete equipment list and CE certification documents were confirmed.

5. Manufacturing – February–March 2025

All equipment manufactured within 45 days.

6. Shipping – April 12, 2025

40-foot HQ containers shipped from Qingdao Port to Rotterdam.

7. Installation – May–July 2025

Our engineers arrived in the Netherlands for 52 days.

We trained 18 workers and provided full electrical and mechanical commissioning.

8. Trial Production – July 2025

Output reached 98% of design capacity during testing.

Production Performance Achieved in the Netherlands

After commissioning, the Planta de bloques de hormigón celular reached all expected performance indicators:

✔ Daily Output: 450–500 m³

✔ Annual Capacity: 150,000 m³

✔ Cutting Accuracy: ±1 mm

✔ Power Consumption: Optimized 9–11 kWh/m³

✔ Waste Rate: <1.8%

✔ Autoclave Efficiency: 10% improved steam utilization

✔ Operating Cost Reduction: 12–15% compared to the client’s previous system

What Our Client Says?

“The automation level is ideal for the Dutch market, where labor costs are high.

Your installation team worked professionally and helped us complete commissioning ahead of schedule.”

Por qué elegirnos?

✔ 20+ Years AAC Manufacturing Experience

✔ Exported AAC Equipment to 80+ Countries

✔ CE-Certified and EU-Compliant Systems

✔ Professional Turnkey Solutions

✔ Competitive Factory Pricing

✔ Strong After-Sales Support & Spare Parts Supply

✔ Multi-language technical support (English, Dutch, German)

Start Your AAC Block Manufacturing Plant?

If you plan to build an AAC block factory, we can provide:

- Customized plant design

- Cost analysis & ROI calculation

- Local market block size recommendations

- CE-certified machinery

- Complete installation & training

- Long-term maintenance service

Contact us today to get a tailored AAC plant proposal for your region.