250,000 m³/Year AAC Block Plant Exported to USA

On October 18, 2024, our company successfully exported a complete 250,000 m³/year AAC Block Plant to USA. This fully automated plant was designed, manufactured, delivered, and commissioned by our engineering team as part of a turnkey service package.

- Annual output: 250,000 m³

- Plant size class: Large AAC Plant (200,000–600,000+ m³/year)

- Suitable investment range: USD 2,000,000–3,000,000

Plant Type:

- Completamente automatico

- Integrated PLC control

- High-precision European-style cutting system

- Sand-based AAC formulation (consistent with Texas raw material availability)

The customer is a well-established Houston-based building materials supplier specializing in:

- Cement-based products

- Lightweight wall materials

- Prefabricated construction

- Energy-efficient building solutions

Customer Business Goals

- Produce high-quality AAC blocks meeting ASTM C1386

- Reduce purchasing reliance on imported AAC

- Supply AAC to the fast-growing Houston–Austin–San Antonio construction corridor

- Enter the modular home market with stable, lightweight, fire-resistant materials

The customer chose us after evaluating multiple suppliers in Europe and Asia, citing our cutting accuracy, engineering capability, and price-to-performance ratio.

Customized AAC Block Plant Exported to USA

To meet the customer’s production and compliance goals, we delivered a fully customized solution.

1. Choosing the 250,000 m³/year Capacity

Based on market analysis in Texas:

- Major contractors require long-term, stable AAC supply

- Texas sees high annual housing starts

- Energy efficiency codes (IECC) support AAC adoption

- Local distributors prefer high-volume suppliers

The selected capacity ensures competitive pricing and rapid ROI.

2. Equipment Modifications for U.S. Standards

We upgraded the plant with:

- UL-certified electrical components

- OSHA-compliant safety locks & guards

- ASTM-compliant mold & cutting tolerance design

- Noise-reduction solutions

- Dust-control system to meet Texas environmental code

3. Automation Improvements for the U.S. Market

Because Texas has higher labor wages, the Impianto AAC includes:

- Automatic mold oiling

- Automatic pre-curing control

- Automatic cutting sequence

- Automatic waste recycling

- Automatic palletizing

This reduced staffing requirements to 14–18 operators per shift.

Advantages of Our AAC Plant AAC Block Plant Exported to USA

High Cutting Accuracy:

Dimensional precision within ±1 mm, meeting ASTM masonry unit standards.

Energy-Efficient Autoclaving:

Steam optimization reduces operating cost—important in regions with high electricity consumption.

Stable & High Strength AAC Blocks:

Produced blocks meet required compressive strength and thermal insulation levels.

Durable Equipment with Long Lifespan:

Autoclaves, molds, and cutting frames are engineered for long-term continuous operation.

Reduced Operational Costs:

Automation significantly lowers:

- Labor cost

- Waste rate

- Utility consumption

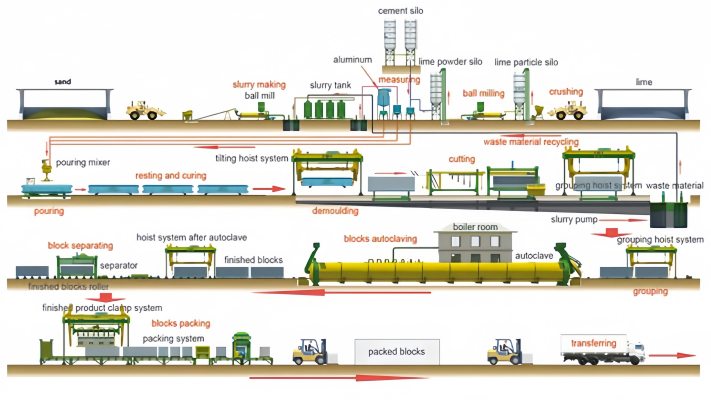

Main Equipment Used in This AAC Plant

The delivered equipment includes:

- Sand ball mill grinding system

- Automated batching & mixing system

- Slurry storage tanks

- Casting & mold circulation system

- Pre-curing chambers

- Vertical & horizontal cutting system

- Tilting table

- 51-meter autoclaves (multi-unit)

- Steam boiler system

- PLC automation control center

- Finished block packing machine

Processo produttivo completo

- Lavorazione e macinazione della sabbia

- Miscelazione dei liquami

- Colata in stampo

- Pre-indurente

- Inclinazione e sformatura

- Taglio di precisione orizzontale e verticale

- Raggruppamento e sterilizzazione in autoclave

- Ciclo di polimerizzazione a vapore

- Ispezione finale

- Imballaggio e pallettizzazione automatizzati

I nostri ingegneri hanno garantito una produzione stabile sin dal primo giorno.

Service Process – From Inquiry to Final Trial Run

Initial Inquiry (January 2024): Customer contacted us requesting a feasibility analysis for AAC production in Texas.

Raw Material Testing (February 2024): We tested Texas river sand samples from the customer’s site.

Factory Visit (March 2024): Customer visited our facility and reviewed live demonstrations of our cutting and autoclave systems.

Contract Signing (April 2024): Final plant configuration agreed and contract executed.

Production & Quality Inspection (May–September 2024): Equipment manufactured, assembled, and tested.

Shipment to Houston (October 18, 2024): All containers shipped with full inspection reports and certifications.

On-site Installation (November–December 2024): Our engineers traveled to Houston to supervise installation.

Commissioning & Staff Training (January 2025): Full system debugged; operators trained to run the plant independently.

Trial Production (January 28, 2025): First batch of AAC blocks produced successfully.

Post-Commissioning Results

- Monthly output: 20,000–24,000 m³

- Annual target on track: 250,000 m³

Blocks passed:

- Density test

- Strength test

- Dimensional tolerance

- Fire resistance

- Thermal conductivity test

All fully compliant with ASTM C1386 and suitable for Texas construction requirements.

What Our Client Says?

“Our new AAC block production line has truly exceeded our expectations. The cutting accuracy is exceptional, and the entire system operates smoothly and reliably. The high level of automation has significantly lowered our labor costs here in Texas, which gives us a major competitive advantage. Your engineering team supported us throughout every stage of installation and commissioning, ensuring a seamless start-up. Overall, we are extremely satisfied with the performance and quality of the equipment.”

Perché scegliere noi?

- ✔ 20+ years AAC plant manufacturing experience

- ✔ Exported to 80+ countries

- ✔ Advanced precision cutting technology

- ✔ Full compliance with ASTM + UL + OSHA

- ✔ Competitive cost vs. European suppliers

- ✔ Complete turnkey engineering services

- ✔ Fast after-sales response & long-term support

- We deliver reliable, scalable AAC solutions for U.S. investors seeking profitability and quality.

Start Your AAC Block Manufacturing Plant?

Whether you are planning a piccolo, medium, o large-scale AAC factory, we can provide:

- Feasibility report

- Plant design

- Equipment configuration

- Cost analysis

- Turnkey delivery and installation

- Long-term technical support

Contact us to get a complete proposal for your AAC block plant project.