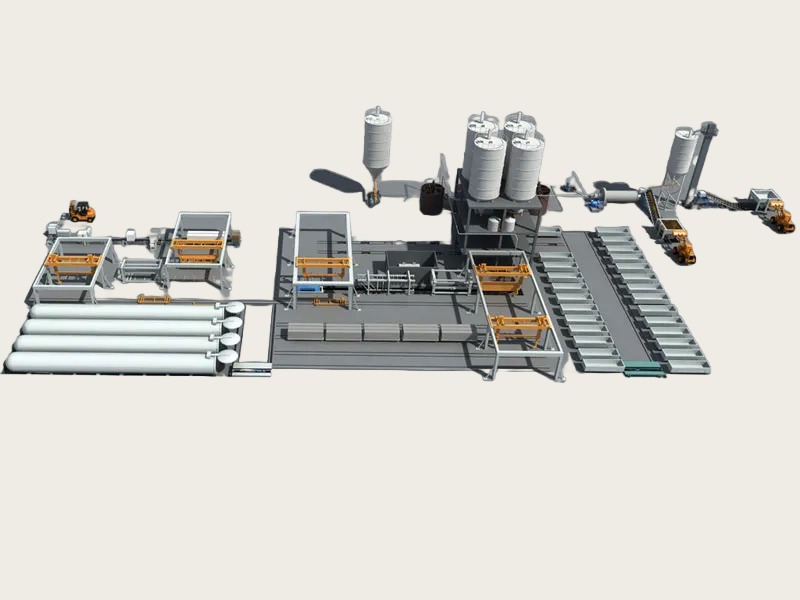

The Lightweight Block Machine (LBM) is a complete set of equipment specifically designed for manufacturing lightweight blocks.

It can produce both CLC blocks (Cellular Lightweight Concrete), which utilize fly ash, slag, and foamed cement, and AAC blocks (Autoclaved Aerated Concrete), which are cured under high temperature and pressure.

Lightweight Block Machine Price

Small CLC semi-automatic line: $ 5,000–30,000

Medium-sized fully automated AAC line: $ 300,000–800,000

Large-scale AAC turnkey plant: $ 1,000,000–1,500,000

Final price depends on production capacity, automation level, autoclave specifications, and auxiliary equipment configuration.

Types of Lightweight Block Machine

Lightweight Block Machine

Process: Chemical Foaming + Atmospheric Curing

Capacity/batch: 15–100 m³

Automation Level: Semi-automatic / Fully automatic

Used for: Urban cast-in-place, roof slope finding, low-rise filling

Initial Investment: Low

Lightweight Block Machine Process

CLC Manufacturing Process:

Batching → Foaming agent dilution → Forced mixing → Mold pouring → Ambient temperature curing for 24 hours → Demolding → Natural curing for 7–14 days → Finished product packaging

AAC Manufacturing Process:

Raw material grinding → Batching → Aluminum powder gas generation → Static pre-curing → Cutting → Autoclaving for 12 hours → Finished product packaging

Main Machine Used Lightweight Block Manufacturing

CLC dedicated foaming and mixing machine

Function: Produces a uniform foam slurry from cement, fly ash, water, and foaming agent in one operation.

Technical Highlights:

- Twin-shaft forced mixing and high-speed flying cutters combine to uniformly mix a 400 kg/m³ foam slurry in just 30 seconds.

- 45° angled discharge door allows for rapid, drip-free emptying in 5 seconds.

- Optional 2.2 kW built-in physical foaming pump enables on-site foaming and mixing and pouring, eliminating secondary transport.

Foaming Agent & Aluminum Powder Metering System

Function: Provides a physical foaming agent for CLC and an aluminum powder gasifier for AAC, precisely controlling porosity.

Technical Highlights:

- Closed-loop control using a servo screw and load cell, achieving a metering error of ≤±0.5%.

- All-stainless steel piping, resistant to alkali and corrosion.

- One-touch switching between CLC and AAC recipes, with storage for 99 recipes.

- Automatic cleaning to prevent spontaneous combustion of residual aluminum powder.

Cutting Machine

AAC Turntable Cutting Machine

- After turning the blank 90°, six wires are cut simultaneously, with a dimensional error of ≤±1 mm.

- Servo-controlled crosscutting and longitudinal cutting, with a maximum speed of 3 minutes per die.

- Vacuum chip extraction and water circulation ensure a dust-free workshop.

CLC Multi-Blade Saw Cutting Machine

- Diamond saw blade assembly, capable of cutting 5–10 blades simultaneously, with a daily output of 300 m³.

- Track-type automatic feeding, adjustable cutting thickness from 50–300 mm.

- Water-cooled machine head, resulting in a smooth cut surface that eliminates the need for plastering.

Automatic Palletizer& Strapping Machine

Function: Automatically palletizes, straps, and laminates finished products after they leave the production line, saving 3-4 people per shift.

Technical Highlights:

- Robotic palletizing, pallet size 1.0 × 1.2 × 1.8 m, adjustable layer height.

- Automatic PET plastic-steel strapping, with adjustable tension from 400–2,000 N.

- Online weighing and coding, with QR code batch traceability.

- Integration with ERP for automatic delivery order generation.

Autoclave (AAC-specific, φ2.0 x 31 m)

Function: Performs a hydrothermal synthesis reaction in high-temperature, high-pressure saturated steam to generate tobermorite crystals, achieving an AAC strength of ≥4 MPa.

Technical Highlights:

- Design pressure 1.6 MPa, design temperature 204°C, and four-point safety interlocks.

- Quick-opening door structure, opening/closing in just 3 minutes.

- Waste heat recovery system, reducing steam consumption by 15%.

- Fully automatic blowdown and condensate recovery, ensuring zero emissions.

PLC Control Room

Function: The brain of the entire production line, centrally monitoring recipes, temperature, pressure, output, and energy consumption.

Technical Highlights:

- Siemens S7-1500 series PLC, 512 I/O points.

- 15″ industrial-grade touch screen, real-time animation display of equipment status.

- Cloud data interface, mobile app for remote alarms and OEE analysis.

What is Lightweight Block

The Lightweight Block Machine (LBM) is a complete set of equipment specifically designed for manufacturing lightweight blocks.

It can produce both CLC blocks (Cellular Lightweight Concrete), which utilize fly ash, slag, and foamed cement, and AAC blocks (Autoclaved Aerated Concrete), which are cured under high temperature and pressure.

The application of lightweight block

Lightweight blocks are used in various construction scenarios, including:

- Residential and commercial buildings for interior and exterior walls.

- Partition walls and non-load-bearing partitions.

- Insulation layers in roofs, floors, or cavity walls.

- Low-rise load-bearing structures (depending on the block’s strength).

- Green building projects focused on sustainability and energy efficiency.

Features of Lightweight Blocks

Low Density: They are made using materials or processes that reduce their density, making them lighter per unit volume compared to standard blocks.

Insulating Properties: Many lightweight blocks offer better thermal insulation than heavyweight alternatives, helping to regulate indoor temperatures and reduce energy consumption.

Structural Versatility: Depending on the type, they can be used for load-bearing walls, non-load-bearing partitions, or as insulation layers in composite structures.

Ease of Handling: Their lighter weight simplifies transportation, lifting, and on-site installation, reducing labor costs and physical strain.

Lightweight Block VS. AAC Block

| Indicator | Lightweight Block (CLC) | AAC Block |

| Curing Method | Ambient temperature & pressure | High-temperature & high-pressure autoclaving |

| Density Range | 400–1,200 kg/m³ | 400–700 kg/m³ |

| Construction Impact | Demoldable in 24 hours; site-castable | Factory prefabrication required; 12-hour autoclaving |

| Surface Precision | Requires secondary plastering | Can be directly applied with putty |

| Investment Threshold | Low; mobile-friendly | High; fixed autoclave required |

| Applicable Scenarios | On-site filling, renovation | Prefabricated wall panels for assembly |

Lightweight Block(CLC) Process VS. AAC blocks Process

The AAC production process differences between CLC and AAC blocks can be summarized as room temperature foam curing vs. high-pressure steam curing. Below is a comparison by process:

1. Raw Material Preparation

CLC: Cement + Fly Ash/River Sand + Water + Physical Foaming Agent (Foam generated on-site by a foaming machine

AAC: Cement + Fly Ash/Quartz Sand + Quicklime + Gypsum + Aluminum Powder (Chemical Foaming Agent) + Water

2. Gas Generation/Foaming Stage

CLC: Prefabricated, stabilized foam is injected into the cement slurry via a high-speed mixer, creating a 30–40% closed-cell structure.

AAC: Aluminum powder reacts with the alkaline slurry to release hydrogen dioxide, producing a uniform pore structure of 50–60%. The reaction is completed in a pre-curing chamber at 40–60°C.

3. Molding Method

CLC: Directly cast the entire mold in a large volume, then cut to the desired size using a multi-blade saw.

AAC: Initially cast into a large green body of 3–6 m³, pre-cured and hardened, the product is then precision-cut on six sides using a wire cutter.

4. Curing System

CLC: Curing at room temperature (or 40–60°C in steam) for 24 hours before demolding. Natural curing is then carried out for 20–28 days before shipment.

AAC: After demolding, the green body is placed in an autoclave and cured in saturated steam at 180–200°C and 10–12 bar for 8–12 hours. This chemical reaction forms tobermorite crystals, doubling the strength.

5. Production Cycle and Equipment

CLC: Simple equipment (mixer + foaming agent + mold), low investment, and mobile on-site production; short cycle times but large footprint.

AAC: Requires large equipment such as a ball mill, cutter, and autoclave, requiring high investment and a fixed factory footprint; however, finished products can be produced within 24 hours, demonstrating a high degree of continuity.

6. Energy Consumption and Cost

CLC: Energy consumption is approximately 20–30 kWh/m³, resulting in low overall costs.

AAC: Autoclave energy consumption is approximately 120–150 kWh/m³, but the product is high in strength and dimensional accuracy, resulting in lower overall costs for subsequent masonry.

Our Service:

Turnkey Full-Process Service: From process design, equipment manufacturing to installation, training, and post-commissioning support—we manage every step for seamless production.

Modular Rapid Launch: Main workshop installed in 30 days, production ready in 15 days. Speed up your project with efficient setup.

Smart Cloud Monitoring: Track output, energy use, and real-time fault alerts via mobile. Control operations with cutting-edge tech.

Trusted Globally: 600+ lines worldwide, exported to 80+ countries. Backed by 7×24 localized service teams for responsive support. Your success, globally supported.