150,000 m³/Year AAC Block Manufacturing Plant in Poland

In March 2025, our company successfully exported a 150,000 m³/year AAC block manufacturing plant to a leading construction materials company in Poland.

Capacity: 150,000 CBM/year (Medium AAC Plant)

- Ideal for regional supply in central Poland

- Meets current and projected demand for construction materials

- Automation reduces dependency on high labor costs

- Investment estimate: USD 1.6–1.7 million (equipment only)

- Payback period: approximately 3 years

Plant Highlights:

- Fully automated batching, mixing, and pouring systems

- Precision cutting machines for multiple block sizes (600×200×100–150 mm)

- 8 autoclaves with optimized energy consumption

- SIEMENS PLC-based automation for smooth operation

- CE-certified components meeting European standards

Poland’s construction sector has seen a rapid shift toward sustainable and insulated building materials, driven by:

- Increasing regulations for energy-efficient buildings

- Growing urbanization in cities such as Warsaw, Poznań, and Kraków

- Rising demand for lightweight blocks to reduce structural load and construction time

- Need for eco-friendly materials in residential and commercial projects

Our client, headquartered in Poznań, wanted to expand production, improve block quality, and reduce labor costs by adopting a fully automated AAC production line.

After evaluating local market needs and investment budget, they chose a medium-scale AAC plant, which perfectly balances production capacity and cost-efficiency in Poland.

Customer Needs and Challenges

The Polish client faced several challenges:

- Traditional concrete blocks were heavy and time-consuming to install.

- Labor costs were rising, requiring automation to reduce workforce.

- They needed consistent block quality to comply with EU insulation standards.

- Expansion to neighboring markets (Germany, Czech Republic) required scalable production.

- Previous equipment lacked energy efficiency, increasing operational cost.

Our team provided a customized solution addressing all these concerns, ensuring high production efficiency, stable quality, and compliance with EU standards.

Equipment of AAC Block Manufacturing Plant in Poland

Main Equipment List:

- Raw material batching & mixing system

- Aluminum dosing system

- Pouring and pre-curing machine

- High-precision wire cutting system (horizontal & vertical)

- 8 autoclaves (CE-certified)

- Final packing, stacking, and palletizing system

- PLC-based automation with remote monitoring

Energy-Saving Features:

- Steam-efficient autoclaves

- Heat recovery system

- Low-noise cutting station

- Insulated mixing and autoclave tanks

The AAC blocks making machine was designed for low labor input and high precision, allowing consistent block quality and reduced operational costs.

On-Site Installation & Commissioning

Installation Timeline:

- Engineers arrived in Poznań: April 20, 2025

- Installation and assembly: April–May 2025

- Trial production: June 5, 2025

Key Steps:

- Batching system setup and calibration

- Autoclave installation and steam system testing

- Cutting line alignment and calibration

- Electrical wiring and PLC programming

- Final product handling and packing system setup

Staff Training Included:

- Operation of each equipment section

- PLC and automation system usage

- Maintenance and troubleshooting

- Quality control: density, compressive strength, curing cycle

The plant reached 98% of the target capacity during trial production.

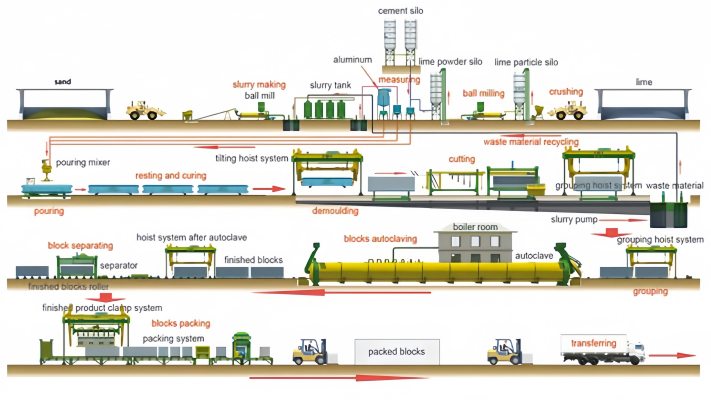

Complete Production Process

- Sand processing & grinding

- Slurry mixing

- Mold casting

- Pre-curing

- Tilting & demolding

- Horizontal & vertical precision cutting

- Grouping & autoclaving

- Steam curing cycle

- Final inspection

- Automated packaging & palletizing

Our engineers ensured stable production from day one.

Production Performance Achieved

Output & Efficiency:

- Daily production: 450–480 m³

- Annual capacity: 150,000 m³

- Cutting accuracy: ±1.5 mm

- Waste rate: <2%

- Power consumption: 9–11 kWh/m³

- Autoclave efficiency: optimized steam utilization

What Our Client Says?

“The AAC plant supplied by your company exceeded our expectations. Automation significantly reduced labor costs, and the cutting precision is excellent.”

Why Choose Us?

- 20+ years of experience in AAC manufacturing

- Exported to over 80 countries worldwide

- CE-certified equipment compliant with EU standards

- Turnkey solutions from design to commissioning

- Strong after-sales support in Europe

- High ROI and energy-efficient operations

- Fully customizable plant layout and capacity

Start Your AAC Block Manufacturing Plant?

Contact us today for a customized AAC blocks plant solution, cost analysis, and turnkey solution tailored to your market.

FAQs for Polish Investors

Medium AAC plants (100,000–200,000 CBM/year) meet regional demand.

Typically 45–60 days.

Yes, all electrical and mechanical components are CE-certified.

600×200×100–150 mm, as well as custom sizes upon request.

Yes, we provide on-site training and manuals for operators and technicians.