220,000 m³/Year AAC Block Manufacturing Plant to Germany

In May 2024, our company successfully exported a fully automatic AAC block manufacturing plant para Germany.

- Annual Capacity: 220,000 m³/year (large AAC plant category)

- Plant Size Category: Large AAC Plant (200,000–600,000 m³/year)

- Setup Cost Range: USD 2,000,000 – USD 3,000,000

- Nível de automatização: Fully automatic with Siemens PLC

- Production Standard: CE-compliant, energy-saving steam curing system

- Application Range:

- Residential low-rise and mid-rise buildings

- Green construction materials

- Lightweight thermal-insulation AAC panels & blocks

The customer is a well-known building materials distributor located in Hamburg, Germany, specializing in prefabricated wall systems and eco-friendly construction materials.

Before working with us, the client was importing AAC blocks from Eastern Europe and wanted to develop their own production facility to reduce material costs and expand their product line into AAC wall panels.

Their key requirements were:

- EU-compliant equipment

- Low energy consumption

- Higher automation to reduce labor cost

- Precision cutting accuracy

- Long-term stable operation

- Turnkey engineering support

After comparing three Chinese suppliers and two European suppliers, they selected us for our export experience, advanced automation, and complete engineering capability.

How We Designed the Customized Solution

After a detailed needs analysis, we proposed a 220,000 m³/year fully automatic AAC plant, tailored to Germany’s local labor cost, energy policies, and land-use regulations.

We provided customization in the following areas:

✔ 1. Fully automatic batching & pouring system

To reduce manpower and enhance accuracy, ensuring consistency for German building quality requirements.

✔ 2. German-language Siemens PLC control system

Compliant with CE and German safety standards.

✔ 3. Energy-saving autoclave steam recycling system

Reduces steam consumption by 15–18%.

✔ 4. High-precision cutting line (±1.0 mm tolerance)

Essential for panel production and high-end construction applications.

✔ 5. Dust-control system for strict environmental compliance

Ensures the factory meets Germany’s environmental protection regulations.

✔ 6. Space-optimized plant layout

Adjusted to the client’s land size and workshop constraints.

Advantages of AAC Block Manufacturing Plant to Germany

1. High-Precision Cutting System

Ensures blocks and panels meet German tolerance standards (±1 mm).

2. CE-Certified Electrical & Safety Design

All components comply with EU safety requirements.

3. Fully Automatic Operation

Automation helps reduce labor cost—especially important for countries like Germany.

4. Energy-Efficient Curing Process

Recycles heat and steam to significantly reduce power consumption.

5. Long Life Span & Stable Output

Designed for 15–20 years of continuous operation with minimal maintenance.

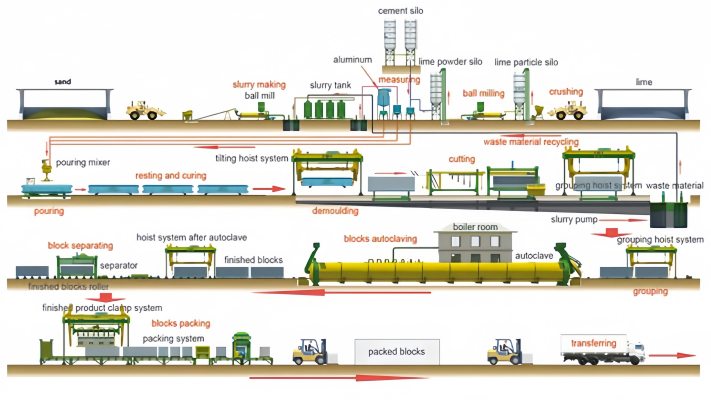

Main Equipment Used in This AAC Plant

- Raw material batching & weighing systems

- Automatic slurry mixing station

- Aluminum dosing system

- Mold and pre-curing section

- Automatic de-molding and tilting crane

- Vertical & horizontal cutting machine

- Waste recycling system

- Autoclave system (Φ2.68 × 36 m)

- Boiler and steam pipeline system

- Finished product packing section

Centralized control system (Siemens PLC)The delivered equipment includes:

Complete Production Process

- Sand processing & grinding

- Slurry mixing

- Mold casting

- Pré-cura

- Tilting & demolding

- Horizontal & vertical precision cutting

- Grouping & autoclaving

- Steam curing cycle

- Final inspection

- Automated packaging & palletizing

Our engineers ensured stable production from day one.

Service Process: From Inquiry to Trial Production

Our service covers the complete lifecycle of an AAC factory setup:

Inquiry & Technical Discussion: The client contacted us in January 2024, requesting a medium-large AAC solution.

Plant Design Proposal: We delivered a detailed layout, cost plan, and energy consumption report within 7 days.

Contract & Production: The client confirmed the order in February 2024.

Manufacturing & Quality Inspection: All equipment completed by April 2024.

Delivery to Hamburg Port: Shipment completed on May 18, 2024.

Instalação e formação:

Our engineers arrived on-site in June 2024 for:

- Installation

- Electrical connections

- Commissioning

- Operator training

Successful Trial Production: Trial run completed on September 2, 2024.

Performance Results After Operation

After 3 months of operation, the factory achieved:

✔ Output Stability:

Reaching 620–650 m³/day average production.

✔ Lower Energy Consumption:

Steam consumption reduced by 15% compared to the client’s previous outsourced blocks.

✔ Cutting Precision:

Panel accuracy reached ±1.0 mm, exceeding the client’s expectations.

✔ Labor Reduction:

Automation allowed the client to operate the entire plant with only 18 workers.

✔ Market Expansion:

The client began supplying AAC products to four German states.

What Our Client Says?

“The AAC plant you delivered to Germany is truly outstanding. The cutting accuracy is exceptional, and the automation has significantly lowered our labor cost.”

Porquê escolher-nos?

✔ 20+ years experience in Fabrico de blocos AAC

✔ Exported to more than 80 countries globally

✔ Strong engineering & installation team

✔ Fully automatic & energy-saving AAC equipment

✔ High-precision cutting suitable for EU markets

✔ Turnkey plant design + training + after-sales support

We are committed to helping German companies build efficient, profitable, and long-lasting AAC factories.

Start Your AAC Block Manufacturing Plant?

Contact us today for a customized AAC plant design, cost analysis, and turnkey solution tailored to your market.