Advanced AAC Block Manufacturing Unit Manufacturer

The AAC Block Manufacturing Unit is a complete system integrating automated batching, mixing, pouring, curing, cutting and autoclaving. It uses fly ash or quartz sand, lime, cement and aluminum powder to produce lightweight, high-strength, heat-insulating and fire-retardant AAC blocks/boards.

We offer fully automated and semi-automated options, with annual capacity ranging from 30,000 to 600,000 cubic meters.

Controlled by PLC intelligence, the unit ensures ±0.5% batching accuracy and ±1mm cutting precision. It features low energy consumption and waste heat recovery, meeting national green building material standards.

Production capacity: 30000m³/Y to 600000m³/Y

Types: semi-automatic/ fully automatic

Various Capabilities of AAC Block Manufacturing Unit for Your Needs

AAC Block Manufacturing Units are divided into small, medium and large scales based on production capacity.

Mini/small AAC Block Manufacturing Unit

Capacity: 30000-100000 m3/year

Autoclave: 1-3 sets

Factory: about 4000-10000m2

Types: semi-automatic/ fully automatic

Features: low initial investment, high flexibility.

Suitable for: Start-ups or enterprises with limited investment and small market demand.

Medium Scale AAC Block Manufacturing Unit

Capacity: 100000-200000 m3/year

Autoclave: 4-8 sets

Factory: about 10000-20000m2

Type: semi-automatic/ fully automatic

Features: stable production capacity, controllable costs, flexibility, large-scale production, etc.

Suitable for: Enterprises with a certain market share and stable demand.

Price of AAC Block Manufacturing Unit

Small AAC Block Manufacturing Unit price:

- Price range: $150,000- $300,000.

- Influencing factors: Actual annual output, brand, quality of key components, additional functions, etc.

- Example: 50,000 m³ AAC Block Manufacturing Unit with reliable components costs around $250,000.

Medium-scale AAC Block Manufacturing Unit price:

- Price range: $500,000- $1,000,000.

- Influencing factors: Annual output, automation degree, performance of key equipment, after-sales service.

- Example: A 150,000 m³ AAC Block Manufacturing Unit with advanced automation costs around $800,000.

Large AAC AAC Block Manufacturing Unit price:

- Price range: Over $1,500,000. Super-large lines (400,000 m³/year and above) can reach $3,000,000 .

- Influencing factors: Large-scale equipment, high-end intelligent control systems, energy-saving technologies, large-capacity autoclave groups, after-sales service.

- Example: A 300,000 m³/year AAC Block Manufacturing Unit with top configuration costs around $2,500,000.

Advantages of AAC Block Manufacturing Unit

- Lighter building weight: AAC blocks are 40% lighter than traditional concrete, greatly reducing the overall weight of the building.

- Fully controllable process: The plant has an integrated production line, allowing full control over the entire process, from raw material input to finished products.

- Flexible production capacity: The AAC Block Manufacturing Unit can produce 30,000 to 600,000 cubic meters of AAC blocks yearly, meeting both small-scale and large-scale needs.

- Stable product quality: Computer-controlled batching and real-time quality monitoring ensure consistent quality for every batch.

- Waste recycling: 70% of raw materials are industrial waste (e.g., fly ash from power plants), turning unused waste into useful building materials.

AAC Block Plant Process

Raw material process → Batching and Mixing → Pouring → Static pre-curing → Cutting → Autoclaving Curing → Finished product Processing

1. Raw Material Processing: Sand is crushed and ground to the required fineness. Cement, lime, and gypsum are stored in silos; aluminum powder is mixed with water to make aluminum slurry.

2. Batching & Mixing: Raw materials are weighed in precise proportions, then fully mixed in a mixer to form uniform slurry.

3. Pouring: The mixed slurry is poured into steel molds. The size and shape of the molds can be designed to meet the desired block specifications.

4. Static Pre-curing: Molds with slurry are moved to a pre-curing area. The slurry hardens gradually under proper temperature and humidity to gain initial strength (usually takes several hours).

5. Cutting: After pre-curing, the material is cut into desired sizes and shapes using high-precision equipment (steel wire or blades).

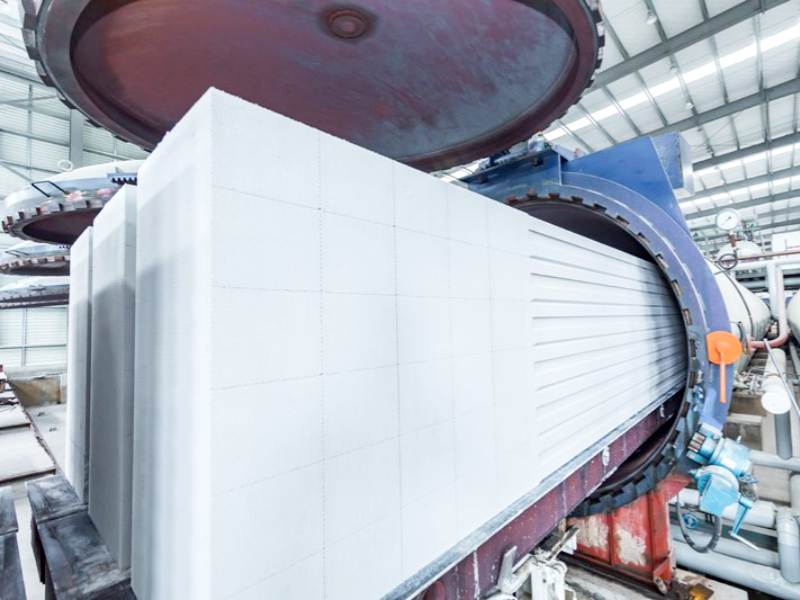

6. Autoclave Curing: Blocks are placed in an autoclave, cured for hours at 175-200°C and 10-15 bar. This greatly boosts their strength and durability.

7. Finished Product Processing: After autoclave curing, blocks are taken out, moved to a storage area, inspected, packaged, and ready for shipment.

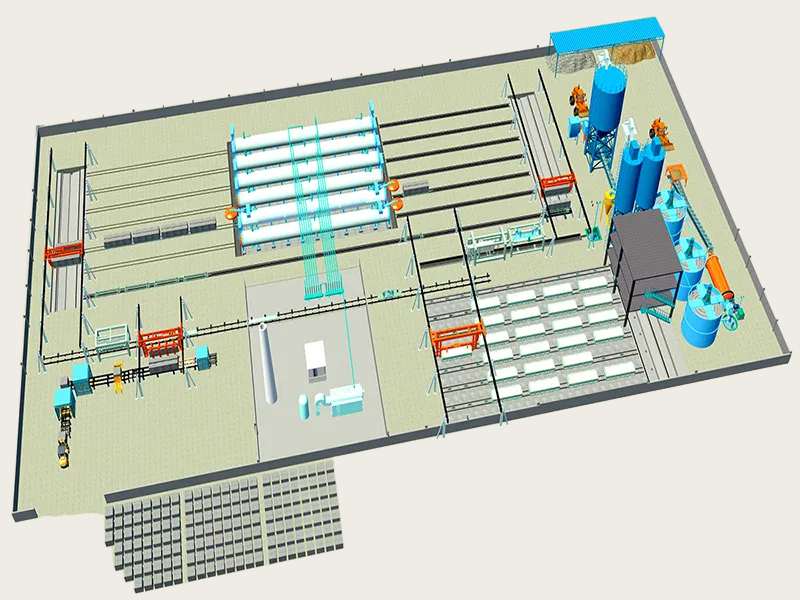

Main Equipment in AAC Block Plant

The AAC block manufacturing unit is a complete system, including 10 types of main equipment and 5 types of auxiliary equipment.

The 10 main equipment items include:

Jaw crusher, ball mill, bucket elevator, slurry metering tank, computer control console, mixer, pouring machine, aerated concrete cutter, autoclave, and boiler.

1. Jaw Crusher

Function: Primarily crushes bulk siliceous raw materials (e.g., sand, silica tailings) or lumpy lime.

Key Effect: Reduces the particle size of materials to below 50mm.

Purpose: Provides qualified raw materials for the subsequent grinding process.

2. Ball Mill

Function: Finely grinds crushed raw materials (e.g., fly ash, sand, lime) to meet production standards.

Key Requirement: Usually requires 80-mesh sieve residue ≤ 15%.

Purpose: Ensures uniform mixing of the slurry in subsequent steps.

3. Bucket Elevator

Function: Vertically conveys raw materials (e.g., fly ash, cement, ground fines) from storage silos.

Delivery Target: Transfers materials to metering systems or mixers.

Key Advantage: Enables automated material transfer.

4. Slurry Metering Tank

Function: Accurately measures liquid raw materials (e.g., water, slurry) and additives.

Operation: Delivers the measured materials to the mixer based on preset recipes.

Precision Guarantee: Ensures a ratio error of ≤1%.

5. Computer Control Panel

Core Role: Acts as the production line’s central control system.

Key Functions: Centrally monitors and controls all process parameters (e.g., raw material ratios, mixing time, foaming temperature, autoclave pressure).

Data Management: Records production data and generates reports.

6. Mixer

Function: Fully mixes raw materials (siliceous material, calcium material, water, aluminum powder gasifier, etc.).

Result: Turns the mixed materials into uniform slurry.

Purpose: Provides qualified mixture for subsequent foaming and pouring steps.

7. Casting Machine

Function: Quantitatively injects mixed slurry into the mold frame.

Key Requirement: Ensures even distribution of the slurry.

Purpose: Lays a stable foundation for subsequent chemical foaming and green body forming.

8. Aerated Concrete Cutting Machine

Principle: Cuts large concrete blocks after initial setting (before full hardening).

Standard Output: Produces standard-sized blocks (e.g., 600 x 200 x 250 mm).

Flexibility: Can also cut to custom sizes as needed.

9. Autoclave

Function: Performs high-pressure steam curing on cut blanks.

Curing Conditions: Operates at 170-200°C and 8-12 atmospheres of pressure.

Reaction Process: Enables raw materials to undergo hydration reaction.

Final Result: Forms a high-strength crystalline structure, producing qualified AAC blocks.

10. Boiler

Function: Supplies high-pressure steam to the autoclave.

Working Method: Burns fuel (e.g., natural gas, coal) to heat water into saturated steam.

Purpose: Meets the thermal energy needs for autoclave curing.

5 types of auxiliary equipment:

Mold frame, base plate, mold car, steaming car, shuttle car, lifting equipment.

1. Mold Frame

Function: Acts as a container for the green body.

Key Roles: Holds the poured slurry; maintains the green body’s shape during foaming and initial setting.

Size Impact: Its dimensions determine the initial size of each green body.

2. Mold Carriage

Function: Carries the mold frame and base plate.

Transport Role: Moves blanks between pouring, curing, and cutting processes.

Key Effect: Helps automate the production process.

3. Steaming and Curing Cart

Function 1: Transports cut billets from the cutting area to the autoclave.

Function 2: Holds the billets during the autoclave curing process.

Function 3: Transports the billets to the finished product area after curing is done.

4. Shuttle Car

Transport 1: Moves cut billets from the cutting area to the autoclave.

Hold during curing: Carries the billets while they undergo autoclave curing.

Transport 2: Moves the billets to the finished product area after curing finishes.

5. Lifting Equipment

Main Function: Lifts and transports mold frames, base plates, and finished blocks.

Key Application 1: Used for mold cleaning and maintenance.

Key Application 2: Used for stacking finished products.

Raw Materials of AAC Block Production

Silica materials: fly ash (accounting for 70%), sand, silicon tailings, ceramic waste, stone processing waste, etc.

Calcium materials: cement, lime

Gas-generating agent: aluminum powder (high purity, ensuring uniform bubble distribution)

Additives: specialized additives to adjust reaction speed and product performance

AAC production has great cost advantages and environmental benefits, thanks to widely available raw materials, especially the reuse of industrial waste.

Core Technology in AAC Block Manufacturing

The core technologies of AAC Block Manufacturing Unit in two key processes: chemical foaming and autoclave curing.

- Chemical foaming: Aluminum powder reacts with alkaline substances in the slurry to produce hydrogen, creating evenly distributed pores and reducing material density by 50%-70%.

- Autoclave curing: In a sealed autoclave, steam hydrates the material, forming tobermorite crystals that give the product high strength and durability.

- A closed-loop water system eliminates waste.

- Waste heat recovery boilers save 15% energy.

- Automated control: A computer system monitors parameters like ingredient ratios, reaction temperature, and autoclave pressure in real time to ensure stable production.

These technologies together make AAC products lightweight, high-strength, and thermally insulating.

What is an AAC block?

AAC (Autoclaved Aerated Concrete) is made from cement, lime, sand/fly ash, water, and aluminum powder (as a blowing agent). Its production involves foaming, pre-curing, cutting, and final autoclaving under high temperature and pressure.

- Pore & Density Features: 80% of its volume is made up of uniform closed pores. Its density (450–650 kg/m³) is only one-third that of traditional bricks.

- Strength & Usage: It has a compressive strength of 3–5 MPa, so it can be used for load-bearing walls and infill walls.

- Environmental Advantage: Its production process is eco-friendly, with no sintering or combustion.

What is the AAC Block Used for?

| Scenario | Application Examples |

| Residential | High-rise infill walls, villa exterior walls, interior partition walls |

| Commercial | Shopping malls, hotels, hospitals, schools |

| Industrial | Factory enclosures, thermal insulation walls for cold storage |

| Special | Fire walls, passive houses, prefabricated buildings, precast stairs/roof slabs |

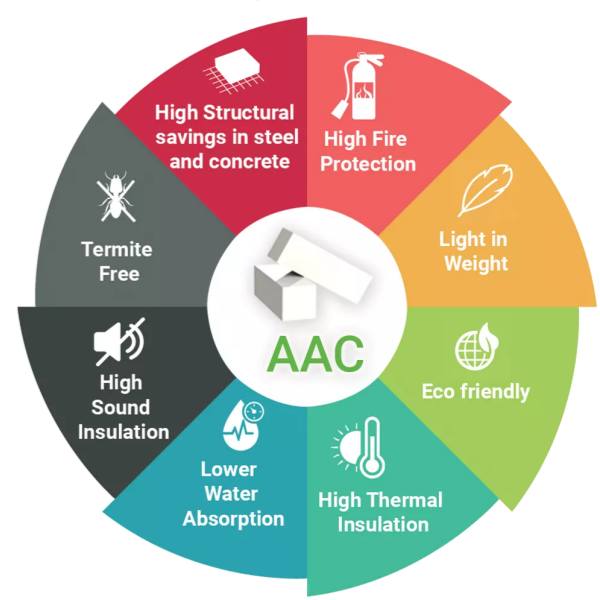

Advantages of Using AAC Blocks

Lightweight and High-Strength:

Its low density, only 1/3-1/4 that of ordinary concrete, effectively reduces the weight of buildings while maintaining high strength to meet structural requirements.

Thermal Insulation:

Its porous internal structure provides excellent thermal insulation, reducing building energy consumption by over 30% and improving energy efficiency.

Excellent Fire Resistance:

As a non-combustible material, it boasts a fire resistance limit of 3-4 hours, effectively slowing the spread of fire and protecting life and property.

Excellent Soundproofing:

Its porous structure effectively blocks sound transmission, enhancing the building’s sound insulation and creating a quiet and comfortable living and working environment.

Easy Construction:

AAC blocks are precisely sized and can be sawed, planed, and nailed, making the construction process simple and convenient, improving efficiency and shortening the construction period.

Environmentally Friendly:

The production process consumes industrial waste, reducing environmental pollution. No harmful gases are released during use, meeting green building requirements.

Profitability of an AAC Block Manufacturing Unit

Cost per Cubic Meter:

- Raw material cost: About 150-200 RMB (fly ash makes up 30%).

- Energy cost: 80-120 RMB (mainly for steam).

- Labor and miscellaneous expenses: 50-80 RMB.

- Total cost: Approximately 300-400 RMB per cubic meter.

Market Price & Profit Margin:

- Market price: 500-700 RMB per cubic meter (varies by region).

- Gross profit margin: 30%-40% -significantly higher than traditional blocks (their gross profit margin is about 20%).

2. Profit expectation of AAC Block Manufacturing for Different Scales

| Plant Scale | Annual Capacity (10,000 m³) | Annual Revenue (USD) | Annual Net Profit (USD) | Payback Period |

|---|---|---|---|---|

| Small-scale | 3-10 | $350,000 – $490,000 | $14,000 – $28,000 | 3 – 5 years |

| Medium-scale | 10 – 20 | $700,000 – $1,960,000 | $42,000 – $112,000 | 4 – 6 years |

| Large-scale | 30 and above | $2,100,000+ | $140,000+ | 5 – 7 years |

Services We Offer

1. Project Planning & Design

Based on the client’s needs and actual conditions, provide overall planning and detailed design for AAC Block Manufacturing Unit, including process design, equipment layout, and civil engineering design.

2. Equipment Supply & Installation

- Supply complete sets of AAC Block Manufacturing Unit.

- Undertake equipment installation and commissioning to ensure normal operation, meeting the designed production capacity and product quality standards.

3. Technical Training

Provide professional training for operators, technicians, and managers, covering production processes, equipment operation, maintenance, and quality management.

4. After-Sales Service

Establish a sound after-sales system to offer:

- Daily maintenance guidance

- Fault troubleshooting support

- Spare parts supply

5. Technical Support & Upgrades

- Provide ongoing technical support.

- Offer equipment upgrading or technical transformation solutions (based on client needs and industry trends) to improve production efficiency and product quality.

6. EPC General Contracting

Provide one-stop EPC services, covering design, equipment procurement, civil construction, installation, training, and trial production for a hassle-free experience.