AAC Plant Manufacturer with Custom Solution

We’re a top manufacturer of full-service AAC (Autoclaved Aerated Concrete) production solutions. We design and supply custom AAC Plant to match your capacity needs, with capacities from 30,000 m³/year up to 600,000 m³/year or more.

Our AAC plants turn industrial byproducts (like fly ash and slag) and eco-friendly raw materials into high-quality AAC blocks and panels.

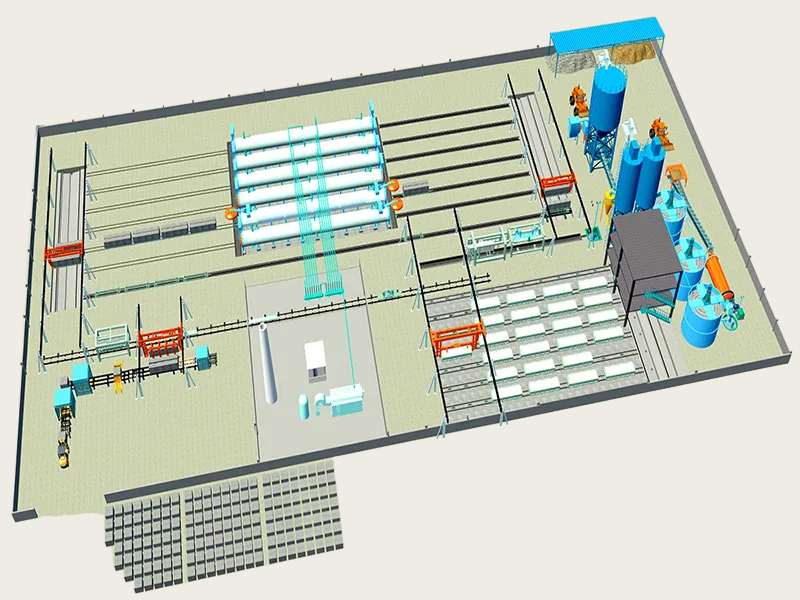

The main equipment used in AAC plant includes a jaw crusher, ball mill, batching station, pouring machine, cutting machine, autoclave, boiler, automatic palletizer, PLC control room, and exhaust heat recovery system.

- Capacity: 30,000m3/year to 600,000m3/year

- Type: semi-automatic tyep and fully automatic type

Various Capabilities of AAC Plant for Sale

According to production capacity, AAC plant can be divided into small, medium and large scale.

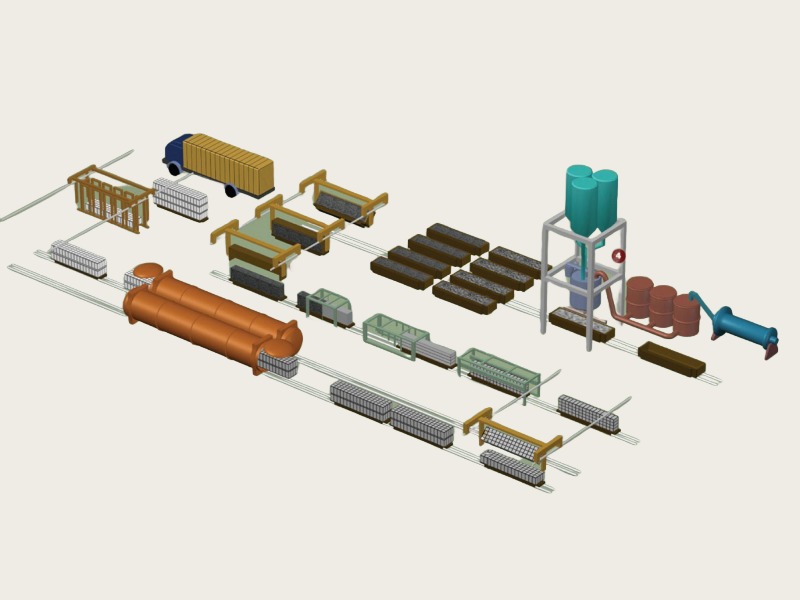

Mini/small AAC Plant

Capacity: 30000-100000 m3/year

Autoclave: 1-3 sets

Factory: about 4000-10000m2

Types: semi-automatic/ fully automatic

Features: low initial investment, high flexibility.

Suitable for: Start-ups or enterprises with limited investment and small market demand.

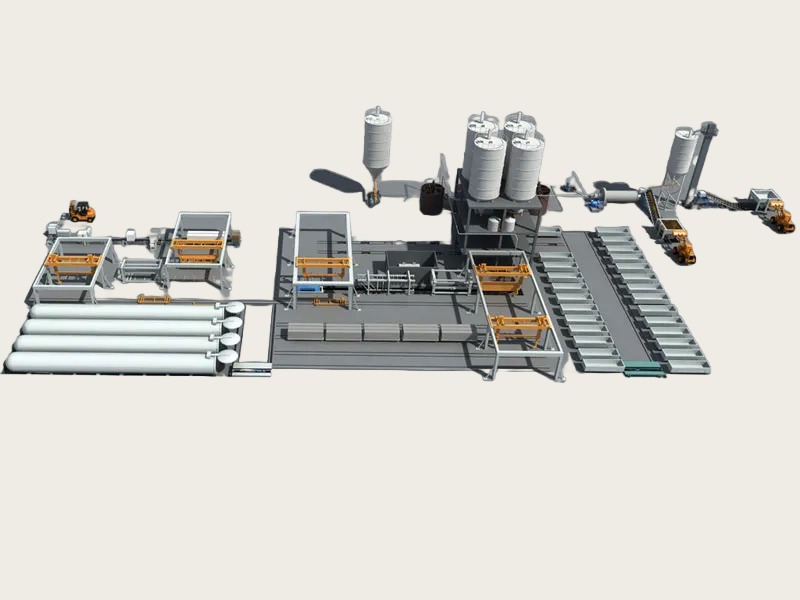

Medium Scale AAC Plant

Capacity: 100000-200000 m3/year

Autoclave: 4-8 sets

Factory: about 10000-20000m2

Type: semi-automatic/ fully automatic

Features: stable production capacity, controllable costs, flexibility, large-scale production, etc.

Suitable for: Enterprises with a certain market share and stable demand.

Brand AAC Block/Panel Machinery Manufacturer

20 years of expertise: A full range of semi-automatic and fully-automatic production lines for Mini, Medium, and Large sizes.

Global EPC projects exceeding 100, exports to over 50 countries, and CE/ISO/ASME certifications.

Guarantee of Turnkey+remote operation and maintenance, with 24/7 technical support.

We’re a professional AAC plant manufacturer with over 20 years of industry experience and advanced technology. We specialize in high-quality semi-automatic and fully-automatic AAC production line equipment.

Our equipment is trusted both at home and abroad—we’ve exported to Southeast Asia, the Middle East, Africa, Europe, and more. Customers praise us for reliable quality, great performance, and full after-sales service.

We also offer custom solutions to fit your needs, making sure our equipment matches your production site and capacity perfectly.

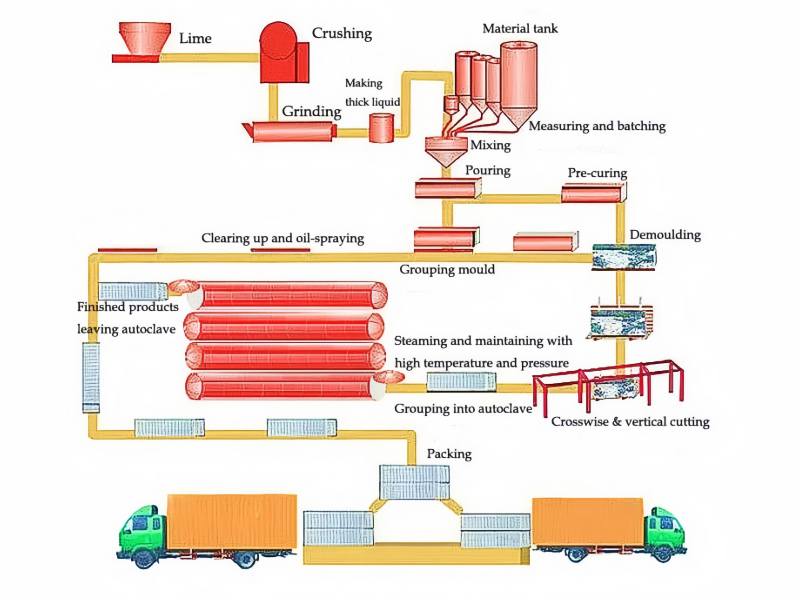

How to Process AAC Block?

Raw material process → Batching and Mixing → Pouring → Static pre-curing → Cutting → Autoclaving Curing → Finished product Processing

1. Raw Material Processing: Sand is crushed and ground to the desired fineness. Cement, lime, and gypsum are stored in silos, and aluminum powder is mixed with water to form an aluminum slurry.

2. Batching and Mixing: The various raw materials are weighed according to precise proportions and then thoroughly mixed in a mixer to form a uniform slurry.

3. Pouring: The mixed slurry is poured into steel molds. The size and shape of the molds can be designed to meet the desired block specifications.

4. Static Pre-curing: The molds containing the slurry are transported to a pre-curing area where the slurry gradually hardens under suitable temperature and humidity conditions to achieve initial strength. This process typically takes several hours.

5. Cutting: After the slurry is pre-cured, it is cut into the desired size and shape using high-precision cutting equipment like steel wire or blades.

6. Autoclave Curing: Blocks are placed in an autoclave and cured for several hours at temperatures of 175-200°C and pressures of 10-15 bar, significantly enhancing the blocks’ strength and durability.

7. Finished Product Processing: After autoclave curing, the blocks are removed from the autoclave and transported to a storage area. After inspection and packaging, they are ready for shipment.

Main Equipment Used in AAC Plant

1. Jaw Crusher

Function: Crushes large limestone, gypsum, and other raw materials into 50-150 mm pieces, making them easy for subsequent fine grinding. It’s key equipment for raw material pretreatment.

Structure: Has a fixed jaw plate and a movable jaw plate, forming a deep crushing chamber. The chamber is lined with replaceable, impact-resistant high-manganese steel tooth plates.

Capacity & Size: Common models handle 100-500 t/h. Motor and main unit are mounted on a steel frame base, taking up just 4-6 m² of space.

2. Ball Mill

Function: Grinds crushed lime, sand, or fly ash into fine powder (80-400 mesh, equal to 0.2-0.045 mm) to boost material reactivity.

Structure: Consists of a horizontal cylinder, wear-resistant liner, and steel ball grinding media. It is driven by a motor, reducer, and large gear.

Key Parameters: Cylinder diameter 1.2-2.4 m; steel ball load 5-30 tons; power 55-800 kW.

3. Batching System

Function: Accurately weighs cement, lime, fly ash, aluminum powder, and water based on production recipes, with an error of ≤ ±0.5%. It comes with multiple silos, metering tools, and conveying equipment.

Module Components: Includes electronic scales, screw feeders, pneumatic butterfly valves, and a PLC touch screen. It supports one-touch recipe selection and completes batching in 30 seconds.

4. Mixing & Casting Machine

Function: Quickly mixes weighed dry materials (e.g., cement, fly ash) with water and aluminum powder into a fluid slurry, then pours the slurry into molds for foaming.

Features: Twin-shaft forced mixing finishes one batch in 60-90 seconds; hydraulic 90° tilting ensures drip-free pouring.

Key Parameters: Effective volume 2-4 m³; motor power 37-55 kW; removable mixing blades (wear life ≥ 30,000 cycles).

5. Tilting Cutter

Function: Cuts pre-cured AAC billets into your desired sizes with an accuracy of ±1 mm. Offcuts are recycled directly in the production line.

Structure: Equipped with three sets of steel wire frames (for longitudinal, transverse, and horizontal cutting). Servo motors sync the lifting and lowering of wires, and automatically compensate for wire wear.

Capacity: Cutting cycle ≤ 5 minutes per mold. It can cut billets into 75-300 mm thickness, 600 mm standard length, or 1200 mm slabs.

6. Autoclave

Function: Uses high-temperature, high-pressure steam to cure AAC green bodies. It completes the hydrothermal synthesis reaction in 8 hours, boosting the green bodies’ strength by 5-8 times.

Specifications:

- Common sizes: Φ2.68×32 m or Φ2.85×38 m.

- Design pressure: 1.6 MPa;

- operating temperature: 200°C.

- Equipped with safety interlock and automatic blowdown functions.

Configuration: A medium-sized AAC production line usually has 4-8 units (can be connected in series or parallel). Energy-saving models come with a waste heat recovery interface.

7. PLC Control Room

Function: Serves as the control center for the entire AAC plant. It supports recipe management, parameter adjustment, process monitoring, energy consumption analysis, fault alarms, and remote viewing via app.

Hardware: Has a reserved OPC UA interface, which enables integration with the factory’s MES/ERP system.

8. Waste Gas Heat Recovery System

Principle: Autoclave exhaust gas at 160°C is preheated to 90°C via a heat exchanger, saving 8-12% of natural gas annually.

Configuration: Plate heat exchanger+circulation pump+automatic temperature control valve.

Hot Sale AAC Block Plant

200,000 m³ AAC plant

Cost: $1500000 million – $2200000

Delivery time: 6-8 months

Advantages: Reduce unit energy consumption by another 8%, gain strong negotiation leverage with suppliers, and expand regional supply coverage.

Suitable for: Leading regional companies and multinational building materials groups.

Advantages of Our AAC Plant

Superior Equipment Performance

German technology authorization combined with Chinese manufacturing costs for optimal performance and affordability.

Modular Design

Enables expansion within 30 days for flexible scale-up.

High Automation Level

Full-automatic lines reduce manual operations, lower labor costs, and boost production precision/stability. Semi-automatic lines offer flexible adjustment to balance efficiency and cost per client needs.

Energy Efficiency & Environmental Friendliness

Equipment designed for energy conservation, low production energy consumption, and effective waste handling to meet environmental standards.

Strong Customization Capability

Tailor-made production line solutions based on client capacity demands, site conditions, and other personalized needs.

Perfect After-Sales Service

Full-range support from installation, training to daily maintenance. A rapid response mechanism ensures timely resolution of production issues.

Why Invest in AAC Plant?

- Strong Market Demand: Market demand keeps rising, with the global market projected to reach $8.7 billion by 2030. Investment prospects are broad, especially in India and Africa where penetration is below 10%.

- Policy Support: Many countries and regions encourage green building materials, creating a favorable policy environment for AAC blocks. Investors can enjoy relevant preferential policies.

- Significant Economic Benefits: Production profit margins are good, and scale effects emerge with expanded output, further boosting benefits.

- Sustainable Development: Using industrial waste for production aligns with sustainable concepts, helping enterprises build a positive social image and enhance market competitiveness.

- Clear Substitution Advantage: Compared to traditional clay bricks, AAC blocks have prominent advantages in performance and environmental protection, with a clear substitution trend. Investing early secures market opportunities.

Autoclaved Aerated Concrete Technology

Chemical foaming combined with high-temperature and high-pressure steam curing creates uniform closed pores, resulting in 40% lighter weight and 6x better insulation than clay bricks.

Core Production Technologies

Autoclaved aerated concrete (AAC) production relies on three core technologies:

- Raw material proportioning: Determines optimal ratios based on material properties and product performance requirements to ensure slurry fluidity, foaming effect, and final quality.

- Foaming technology: Uses aluminum powder reacting with alkaline materials to generate hydrogen bubbles; precise control of temperature and time ensures ideal pore structure.

- Autoclave curing: Cures cut blanks in high-pressure autoclaves under high temperature/pressure to form stable crystal structures, enhancing strength and durability. High precision in autoclave control and curing is critical for quality.

What is AAC?

AAC is a porous, lightweight prefabricated building material made by foaming siliceous and calcareous materials with aluminum powder, then autoclaving.

It is made from a mixture of natural materials such as sand, cement, lime, gypsum, and water, with aluminum powder added as a foaming agent. The aluminum powder reacts with the alkaline components in the mixture to produce hydrogen, which forms tiny bubbles within the wet material, creating a unique porous structure.

Curing the blocks under high temperature and pressure in an autoclave significantly enhances their strength and durability.

AC Block Features and Benefits

Lightweight: 50% lighter than traditional bricks, reducing building weight, easing transportation, and lowering infrastructure investment costs.

Thermal Insulation: Porous structure enables excellent insulation, reducing heating and cooling energy consumption for long-term energy savings.

Fire Resistance: Non-combustible material remains stable at high temperatures for extended periods, providing reliable fire safety protection.

Sound Insulation: Porous properties deliver strong sound absorption, ideal for noise-sensitive spaces like residences, offices, and hospitals.

Durability: Resistant to weathering, pests, and chemical corrosion with a long service life, cutting building maintenance and replacement costs.

Environmental Friendliness: Uses industrial waste like fly ash in production to reduce pollution; lower energy consumption than traditional brick manufacturing for greener operations.

Application of AAC Block and Panel

AAC block factories’ products are widely used in residential, commercial, school, hospital, factory, cold storage, and prefabricated buildings.

- Municipal projects: road medians and backfilling of municipal pipeline trenches.

- Agricultural projects: greenhouse wall construction.

- Defense projects: walls and protective structures for some military facilities.

AAC Blocks VS. Clay Bricks

| Performance Indicator | AAC Block | Clay Brick | Conclusion Interpretation |

| Weight | 400–650 kg/m³ | ≈1 800 kg/m³ | 2.7 times lighter, saving transportation costs and structural steel consumption |

| Thermal Conductivity | 0.12 W/m·K | 0.81 W/m·K | 6 times better insulation; indoor temperature 5℃ lower in summer, saving 30% on air conditioning |

| Fire Resistance | 4–6 hours | 2 hours | Doubles escape time in case of fire |

| Construction Efficiency | 3–3.5 times faster | Manual masonry | Large panels + lightweight feature shorten construction period by 30–40% |

| Environmental Friendliness | Uses solid waste like fly ash, zero cultivated soil consumption | Topsoil extraction + coal burning | Reduces CO₂ emissions by approximately 1,200 tons per 10,000 m³ of AAC |

| Strength & Durability | 3–5 MPa, increasing with age | 3.5–5 MPa, no increase with age | Lightweight yet equally strong, with better weathering resistance |

| Dimensional Accuracy | ±1 mm, no plastering needed | ±5 mm, requiring thick plastering | Saves 70% mortar and 60% plastering labor |

| Water Absorption | ≤20% | 20%+ | Reduces moisture regain and efflorescence issues |

| Sound Insulation | 45 dB (200 mm wall) | 50 dB (230 mm wall) | Achieves equivalent sound insulation with thinner walls |

| Whole Life Cycle | Over 60 years, recyclable | 30–50 years, hard to recycle | Can be crushed and remade after building decommissioning |

Services We Offer

- Project Planning & Design

Provide overall planning and detailed design schemes for AAC plants based on client needs and actual conditions, including process design, equipment layout, and civil engineering design. - Equipment Supply & Installation

Supply full sets of AAC production line equipment, and undertake installation and commissioning to ensure normal operation, meeting designed capacity and product quality standards. - Technical Training

Offer professional training for operators, technicians, and managers covering production processes, equipment operation, maintenance, and quality management. - After-Sales Service

Establish a sound after-sales system providing daily maintenance guidance, fault troubleshooting, and spare parts supply to ensure continuous stable production. - Technical Support & Upgrades

Provide ongoing technical support and offer equipment upgrading/technical transformation solutions based on client needs and industry trends to improve efficiency and quality. - EPC General Contracting

One-stop EPC services from design, equipment procurement, civil construction, installation, and training to trial production for a hassle-free experience.

FAQ

The compressive strength is 3.5-5.0 MPa, exceeding the standard for red brick.

- Advantages: Lightweight, thermally insulating, fireproof, and easy to process.

- Disadvantages: Requires waterproofing.

- Small plant: 3-6 months

- Medium plant: 6-12 months

- Large plant: 12-24 months

Laboratory tests show no strength loss for 60 years, and the actual lifespan is the same as the building’s lifespan.

Consume 70% of industrial solid waste and emit only 1/3 the CO₂ of traditional blocks.

Twice a year, routine maintenance is required, and remote diagnostics allow >90% of faults to be resolved online.

Custom sizes are available. Blocks can be cut to any thickness from 75–300 mm, with standard 600 mm lengths or large 1200 mm lengths.

Mini: 400,000-800,000 USD, medium: 1.2-1.8 million USD, and large: 2.2-3.5 million USD.