150,000 m³/Year AAC Block Manufacturing Plant in Poland

In March 2025, our company successfully exported a 150,000 m³/year AAC block manufacturing plant to a leading construction materials company in Poland.

Capacity: 150,000 CBM/year (Medium AAC Plant)

- Ideal for regional supply in central Poland

- Meets current and projected demand for construction materials

- Automation reduces dependency on high labor costs

- Investment estimate: USD 1.6–1.7 million (equipment only)

- Payback period: approximately 3 years

Plant Highlights:

- Fully automated batching, mixing, and pouring systems

- Precision cutting machines for multiple block sizes (600×200×100–150 mm)

- 8 autoclaves with optimized energy consumption

- SIEMENS PLC-based automation for smooth operation

- CE-certified components meeting European standards

Poland’s construction sector has seen a rapid shift toward sustainable and insulated building materials, driven by:

- Increasing regulations for energy-efficient buildings

- Growing urbanization in cities such as Warsaw, Poznań, and Kraków

- Rising demand for lightweight blocks to reduce structural load and construction time

- Need for eco-friendly materials in residential and commercial projects

Our client, headquartered in Poznań, wanted to expand production, improve block quality, and reduce labor costs by adopting a fully automated AAC production line.

After evaluating local market needs and investment budget, they chose a medium-scale AAC plant, which perfectly balances production capacity and cost-efficiency in Poland.

Customer Needs and Challenges

The Polish client faced several challenges:

- Traditional concrete blocks were heavy and time-consuming to install.

- Labor costs were rising, requiring automation to reduce workforce.

- They needed consistent block quality to comply with EU insulation standards.

- Expansion to neighboring markets (Germany, Czech Republic) required scalable production.

- Previous equipment lacked energy efficiency, increasing operational cost.

Our team provided a customized solution addressing all these concerns, ensuring high production efficiency, stable quality, and compliance with EU standards.

Equipment of AAC Block Manufacturing Plant in Poland

Main Equipment List:

- Raw material batching & mixing system

- Aluminum dosing system

- Pouring and pre-curing machine

- High-precision wire cutting system (horizontal & vertical)

- 8 autoclaves (CE-certified)

- Final packing, stacking, and palletizing system

- PLC-based automation with remote monitoring

Energy-Saving Features:

- Steam-efficient autoclaves

- Heat recovery system

- Low-noise cutting station

- Insulated mixing and autoclave tanks

O AAC blocks making machine was designed for low labor input e high precision, allowing consistent block quality and reduced operational costs.

On-Site Installation & Commissioning

Installation Timeline:

- Engineers arrived in Poznań: April 20, 2025

- Installation and assembly: April–May 2025

- Trial production: June 5, 2025

Key Steps:

- Batching system setup and calibration

- Autoclave installation and steam system testing

- Cutting line alignment and calibration

- Electrical wiring and PLC programming

- Final product handling and packing system setup

Staff Training Included:

- Operation of each equipment section

- PLC and automation system usage

- Maintenance and troubleshooting

- Quality control: density, compressive strength, curing cycle

The plant reached 98% of the target capacity during trial production.

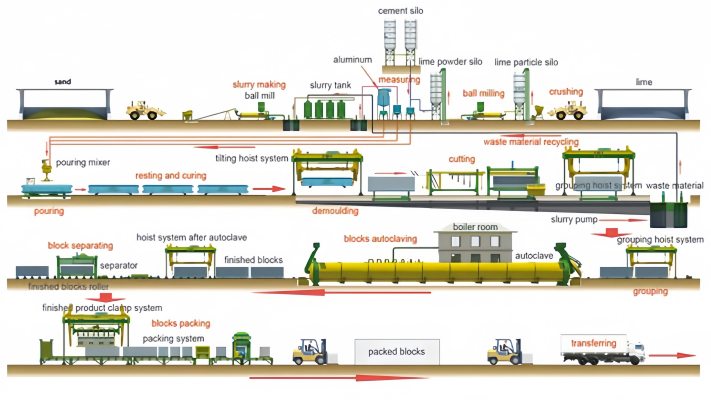

Complete Production Process

- Sand processing & grinding

- Slurry mixing

- Mold casting

- Pré-cura

- Tilting & demolding

- Horizontal & vertical precision cutting

- Grouping & autoclaving

- Steam curing cycle

- Final inspection

- Automated packaging & palletizing

Our engineers ensured stable production from day one.

Production Performance Achieved

Output & Efficiency:

- Daily production: 450–480 m³

- Annual capacity: 150,000 m³

- Cutting accuracy: ±1.5 mm

- Waste rate: <2%

- Power consumption: 9–11 kWh/m³

- Autoclave efficiency: optimized steam utilization

What Our Client Says?

“The AAC plant supplied by your company exceeded our expectations. Automation significantly reduced labor costs, and the cutting precision is excellent.”

Porquê escolher-nos?

- 20+ years of experience in AAC manufacturing

- Exported to over 80 countries worldwide

- CE-certified equipment compliant with EU standards

- Turnkey solutions from design to commissioning

- Strong after-sales support in Europe

- High ROI and energy-efficient operations

- Fully customizable plant layout and capacity

Start Your AAC Block Manufacturing Plant?

Contact us today for a customized AAC blocks plant solution, cost analysis, and turnkey solution tailored to your market.

FAQs for Polish Investors

Medium AAC plants (100,000–200,000 CBM/year) meet regional demand.

Typically 45–60 days.

Yes, all electrical and mechanical components are CE-certified.

600×200×100–150 mm, as well as custom sizes upon request.

Yes, we provide on-site training and manuals for operators and technicians.