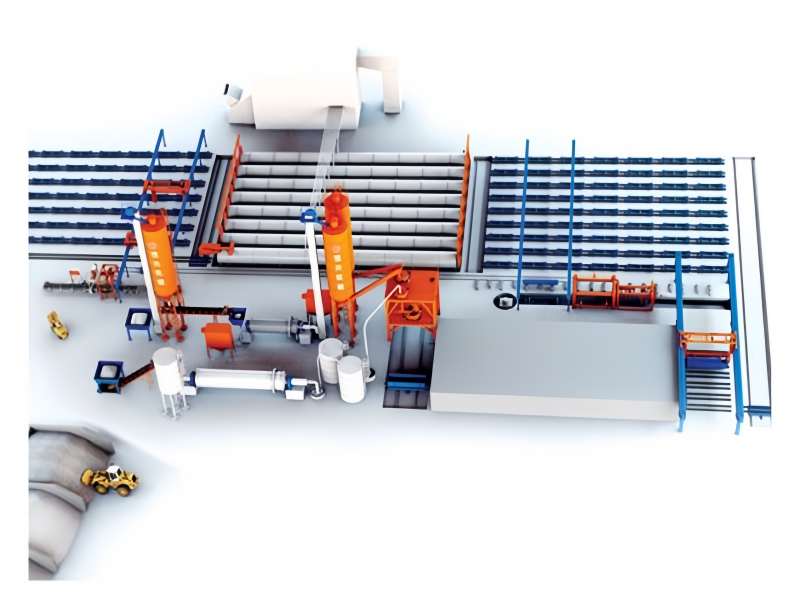

A Small AAC (Autoclaved Aerated Concrete) Block Plant is a compact, high-efficiency production facility built specifically to make AAC blocks.

AAC blocks themselves are lightweight, high-performance building materials, they are widely used in residential buildings, commercial spaces, and industrial construction projects.

What sets small AAC block plants apart from large-scale ones?

- Large plants need huge amounts of space and high initial investment.

- Small AAC block plants, by contrast, are designed for: Entrepreneurs, Local construction companies, Small-to-medium enterprises (SMEs).

- These users often want to enter the building materials market without high upfront costs—and small plants meet that need.

In terms of production capacity, small AAC block plants typically make 30,000 to 100,000 cubic meters of AAC blocks per year. This output is well-matched to the demand of regional construction projects. At the same time, they keep production scheduling flexible, so you can adjust output based on local needs.

Small AAC Block Plant Cost

1. Initial Investment Cost

The initial investment for a small AAC block plant ranges from 100,000 to 250,000 USD, depending on production capacity and equipment configuration. Here’s how the cost breaks down:.

- Equipment Purchase: The core equipment (mixing machine, mold, cutting machine, and small autoclave) accounts for 60-70% of the initial cost, roughly 60,000 to 175,000 USD.

- Site Rental: A small plant needs 500-800 square meters of land (including production area and storage). In most regional areas, annual rental costs range from 5,000to12,000 USD.

- Staff Training & Certification: Training 3-5 operators (for equipment safety and production standards) costs 2,000 to 4,000 USD, including local regulatory certification fees.

Compared to large AAC plants (which cost $500,000+ USD), small plants offer a 50-60% lower entry barrier – ideal for businesses testing market demand or expanding locally.

2. Operating Costs

Monthly operating costs for a 10,000 cubic meter/year plant average 6,000 to 8,500 USD, with clear cost-saving advantages:.

2.1 Raw Materials: AAC blocks use low-cost, locally available materials:

- Cement (30% of cost, about 150/tonUSD),

- Sand(2520/ton USD),

- Lime (20%, about 80/ton USD)

- Aluminumpowder(52,000/kg USD).

Producing 1 cubic meter of blocks requires about 0.2 tons of cement, 0.3 tons of sand, and 0.05 kg of aluminum powder, with totaling 38 to 45 USD per cubic meter.

2.2 Energy Consumption: The autoclave (the most energy-intensive equipment) uses natural gas or electricity. With a natural gas rate of 0.15/cubic meter USD, heating the autoclave for 8 hours/day costs 120/day USD. Monthly energy costs average 3,000 to 4,000 USD.

2.3 Maintenance: Routine maintenance ( lubrication, filter replacement, and minor part repairs) costs 500 to 800 USD/month. Most equipment comes with a 1-year warranty, reducing unexpected repair costs.

3 Long-Term Cost vs. Return Analysis

With a production cost of 38 to 45 USD per cubic meter and a market price of 100 to 120 USD per cubic meter, a small AAC block plant generates a gross profit of 55 to 75 USD per cubic meter..

For a 10,000 cubic meter/year plant:

- Annual gross revenue: 1.0 million to 1.2 million USD.

- Annual total costs (initial investment amortized over 5 years + operating costs): about 120,000 USD (initial amortization)+72,000-102,000USD (operating) = 192,000 to $222,000 USD

- Annual net profit: 778,000 to 988,000 USD.

Most clients recoup their initial investment within 12 to 18 months– a faster ROI than many other construction-related investments.

Technical Parameters of Small AAC Block Plant

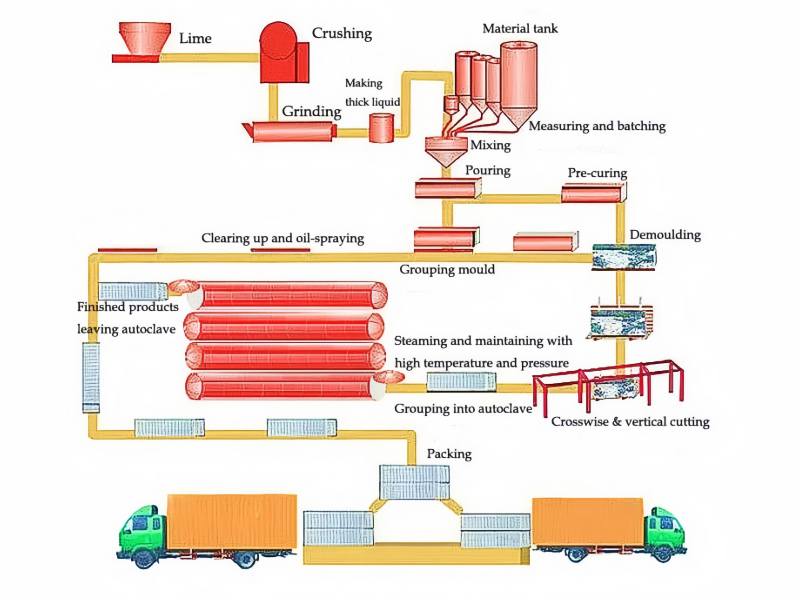

Small AAC Block Plant Process

① Xom ashyoni maydalash: Kimyoviy reaktsiyalarni osonlashtirish uchun kul (yoki qum), ohak va tsement unga o'xshash noziklikka qadar maydalanadi.

② Aralashtirish: Kukun, suv va ko'pikli vositani (alyuminiy kukuni) katta mikserga quying va bir necha soniya ichida ko'piklanish boshlanadi.

③ Qolib ichida ko'pik hosil qilish: Suyuqlik qolipga quyiladi, bu erda pufakchalar uning hajmidan ikki baravar kengayib, yashil tanani hosil qiladi.

④ Quritish: Yashil tanasi qattiqlashishi uchun xona haroratida 2-3 soat davomida qoldiriladi.

⑤ Burilish va kesish: Tel katta yashil tanani aniq o'lchamdagi kichik qismlarga kesish uchun ishlatiladi. Chiqindilar avtomatik ravishda qayta ishlanadi.

⑥ Avtoklavlash: Kichik bo'laklar yuqori quvvatga erishish uchun 180-200 ° C va 1,0-1,3 MPa 8-10 soat davomida avtoklavga joylashtiriladi.

⑦ Qolipdan ajratish: Sovutgandan so'ng pechdan engil, yuqori quvvatli AAC bloklari/taxtalari chiqadi.

⑧ Qadoqlash va palletlash: Robotlar yoki odamlar tayyor mahsulotlarni to'playdi, shtrix-kodlarni qo'shib, ularni jo'natish uchun to'g'ridan-to'g'ri yuklaydi.

Main Equipment Used in Small AAC Block Plant

- Jag'li maydalagich / sharli tegirmon: Toshni maydalab kukun holiga keltiradi.

- Mikser: Xom ashyoni yaxshilab aralashtirish uchun ishlatiladi.

- Kalıplar va yon plitalar: Qoliplar AAC bloklarini shakllantirish uchun ishlatiladi va yon plitalar qolip yig'ilishining muhim qismidir. Misol uchun, kichik AAC ishlab chiqarish liniyasi 15 ta qoliplar to'plami va 162 ta yon plitalarni talab qilishi mumkin.

- Kesuvchi: Nozik kesgichlar oldindan qattiqlashtirilgan bloklarni kerakli o'lchamlarda kesish uchun ishlatiladi.

- Avtoklav: Gazlangan beton bloklarni bug 'bilan quritish uchun ishlatiladigan katta bosimli idish. Kichik AAC ishlab chiqarish liniyasi odatda 3-4 avtoklavni talab qiladi.

- O'tkazish va tashish uskunalari: Ishlab chiqarish jarayonida qoliplarni, bloklarni va aravachalarni siljitish uchun ishlatiladigan moki va kranlar kabi.

Jag' maydalagich

Mikser

Kalıplar va yon plitalar:

Kesuvchi

Avtoklav

O'tkazish va tashish uskunalari

Kichik AAC blokli zavodning afzalliklari

Kam investitsiyalar: Boshlang'ich investitsiyalar past bo'lib, yirik zavodning investitsiya qiymatining atigi 1/6–1/8 qismini talab qiladi.

Mahalliy bozor uchun javob beradi: Due to their smaller production capacity, small AAC production lines can effectively serve the local construction market, reducing transportation costs for raw materials and finished products.

Moslashuvchan sayt: Hatto 4000 kvadrat metrlik eski omborni ham aylantirish mumkin.

Oson kengaytirish: Keyinchalik uskunalarni qo'shish orqali ishlab chiqarish quvvatini ikki baravar oshirish mumkin.

Tez to'lov: Vaziyatni o'rganish shuni ko'rsatadiki, uskunalar to'lovlari 3-4 oy ichida tiklanadi.

Ways to Reduce Setup Costs for Small AAC Manufacturing Plant

- Yarim avtomatlashtirilgan yoki qo'lda ishlaydigan uskunani tanlash: Agar sizning byudjetingiz cheklangan bo'lsa, to'liq avtomatlashtirilgan uskunadan ko'ra yarim avtomatik yoki qo'lda ishlaydigan uskunani tanlash dastlabki sarmoyani sezilarli darajada kamaytirishi mumkin.

- Xom ashyoni mahalliy manbalardan olish: Mahalliy yetkazib beruvchilardan xom ashyo sotib olish transport xarajatlarini kamaytirishi mumkin.

- Konteynerdan foydalanish, prefabrik temir konstruktsiyalar an'anaviy beton zavodlariga qaraganda 30% arzonroq.

- Uskunalar ishlab chiqaruvchilari bilan muzokaralar olib borish: Uskunalar ishlab chiqaruvchilari bilan yaxshiroq narxlar, toʻlov shartlari yoki paketli bitimlar boʻyicha muzokaralar olib borishga harakat qiling.

- Samarali zavod tartibi: Haddan tashqari infratuzilma va uskunalarga bo'lgan ehtiyojni minimallashtirish uchun samarali zavod sxemasini loyihalash.

AAC bloklarining afzalliklari

AAC blocks from small plants meet global quality standards (e.g., ASTM C1386 in the US, EN 12600 in Europe) and offer unmatched benefits for construction:

- Lightweight: Density of 500-700 kg/cubic meter – 30-50% lighter than traditional concrete blocks. Reduces structural load on buildings, cutting foundation costs by 15-20%.

- Issiqlik izolyatsiyasi: Thermal conductivity of 0.12-0.18 W/(m·K) – lower than brick (0.8 W/(m·K)) or concrete (1.5 W/(m·K)). Helps buildings save 30-40% on heating and cooling costs.

- Fire Resistance: Non-combustible material with a fire rating of 2-4 hours (depending on thickness). Meets strict fire safety codes for residential and commercial buildings.

- Eco-Friendly: Uses 50% less cement than traditional blocks and reduces carbon emissions by 30%. AAC blocks are also 100% recyclable—aligning with green building trends (LEED, BREEAM).

Small AAC Plant Cost VS. Large AAC Plant Cost

| Ko'rsatkich | Small Line (30,000 m³/year) | Katta chiziq (yiliga 300 000 m³) | Izohlar |

| Yagona chiziqli investitsiyalar | 0,475 million dollar | 3,0–3,5 million dollar | Katta chiziqning taxminan 1/6-1/7 qismi |

| To'lov muddati | 3-4 oy | 12-18 oy | Kichik o'simliklar tezroq pul oqimiga ega |

| Birlik uchun energiya iste'moli | 34 kVt/m³ | 29 kVt/m³ | Bo'shliq < 15%, bu maqbuldir |

| Kengayish qiyinligi | Modulli +50% sig'imi | Yangi zavod qurish va tasdiqlashni talab qiladi | Keyingi bosqichda istalgan vaqtda yangilanishi mumkin |

| Boshqaruv qiyinligi | 15 kishi bilan ishlaydi | 80+ kishidan iborat jamoa | Kichik o'simliklarning mehnat xarajatlari va murakkabligi sezilarli darajada kamayadi |

Technical Support & After-Sales Service

Professional Team:

- Pre-Installation Consultation: Site assessment to optimize layout (e.g., minimizing material transport distance) and ensure compliance with local building codes.

- On-Site Training: 1-week on-site training for operators, covering equipment operation, quality control, and emergency protocols.

- 24/7 Technical Hotline: Engineers are available via phone/email to resolve issues (e.g., equipment malfunctions, production delays) within 4 hours.

After-Sales Guarantee:

We stand behind our equipment with a comprehensive after-sales package:

- Warranty: 1-year full warranty on all core equipment (mixer, autoclave, cutting machine) and 2-year warranty on electrical components.

- Spare Parts Supply: A global spare parts warehouse (with locations in the US, Germany, and China) ensures delivery of replacement parts within 3-5 business days.

- Annual Maintenance Visits: A free annual inspection by our technicians to optimize equipment performance and extend service life.