Leading the way

AAC Block Manufacturing Plant

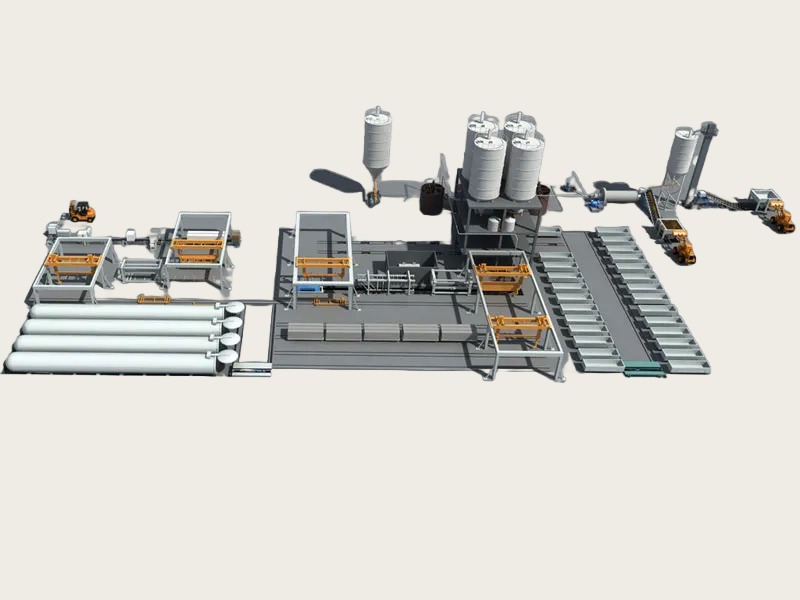

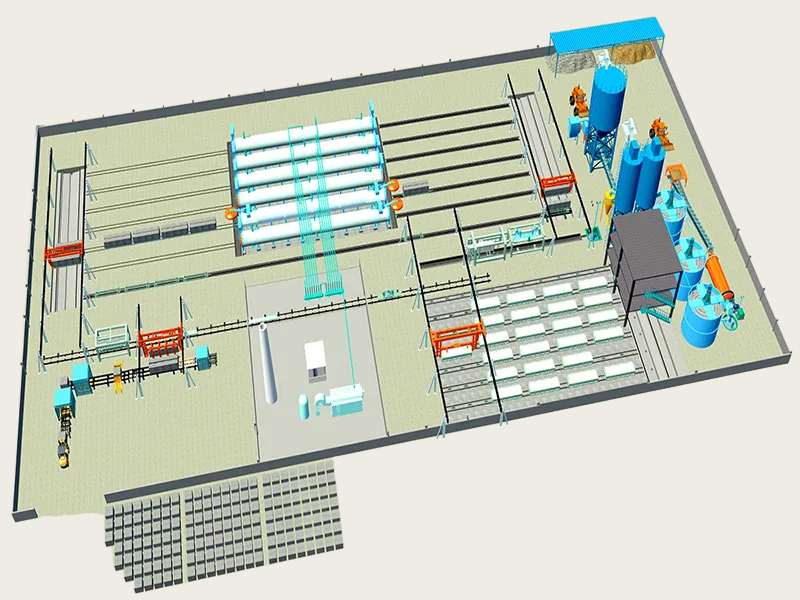

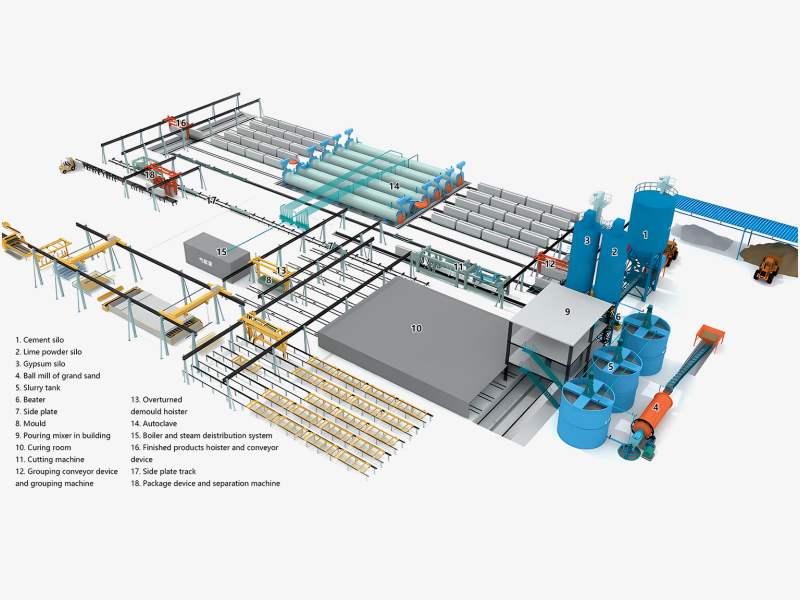

Aerated concrete block (AAC) manufacturing plant, also known as AAC block plant, is a complete production system that processes a variety of raw materials into high-performance building materials AAC blocks through the coordinated operation of multiple equipment.

Its core is to mix cement, lime, fly ash (or sand), gypsum, aluminum powder (foaming agent) and other raw materials in a scientific proportion, and then go through a series of processes such as batching, mixing, pouring, cutting, autoclaving and curing to finally produce lightweight, high-strength, thermal insulation AAC blocks, ALC panels and other products.

capacity: 30000 to 600000m³/Y

with custom solutions

used for: AAC blocks/panels production

Semi-automatic/fully automatic type

Turnkey project

All-day after-sales service+ overseas warehouse

The Hot Sale AAC Blocks Plant

AAC Block Manufacturing Plant

Capacity: 30000 to 600000m³/Year

Types: semi-automatic/ fully automatic

Capabilities: small/ medium-scale/ large

AAC Block Plant

Capacity: 30000 to 600000m³/Year

Types: semi-automatic/ fully automatic

Capabilities: small/ medium-scale/ large

AAC Block Manufacturing Machinery

Capacity: 30000 to 600000m³/Year

Types: semi-automatic/ fully automatic

Capabilities: small/ medium-scale/ large

AAC Block Making Machine

Capacity: 30000 to 600000m³/Year

Types: semi-automatic/ fully automatic

Capabilities: small/ medium-scale/ large

Small AAC Block Plant

Capacity: 30000 to 100000m³/Year

Types: semi-automatic/ fully automatic

Capabilities: small/ medium-scale/ large

Autoclaved Aerated Concrete AAC Plant

Capacity: 30000 to 600000m³/Year

Types: semi-automatic/ fully automatic

Capabilities: small/ medium-scale/ large

Factory Price

How Much Does An AAC Plant Cost?

As a professional AAC block plant manufacturer and supplier, our AAC plant has competitive prices, and you can get direct after-sales service from the manufacturer.

Our AAC Block Plant Price ranges from $400000 to $3500000 based on different types and capacities. We can provide customized production lines and prices according to your specific needs.

Manufacturing Process

How to produce AAC block

1. Raw material preparation and processing

In the aerated concrete block (AAC) production line, the raw material preparation and processing stage is the key link to ensure the smooth progress of subsequent production and product quality, involving the pretreatment and preparation of multiple core raw materials.

The raw materials in this stage mainly include cement, lime, fly ash, gypsum, aluminum powder (foaming agent) and fine aggregate. Each raw material needs to be processed specifically to meet production requirements.

jaw crusher

ball mill

bucket elevator

waste slurry mixing tank

belt conveyor

vibrating feeder

silo

Jaw crusher

As the first step of raw material rough processing, it crushes large hard raw materials like lime and gypsum into particles meeting the ball mill’s feeding requirements.

Ball mill

It undertakes raw material fine processing, further grinding crushed lime, fly ash and other materials to specific fineness. Grinding effect directly affects block strength and homogeneity.

Silos

As the storage center of raw materials, it stores various raw materials such as cement, lime, fly ash, etc., to achieve classified storage and stable supply of different materials.

Bucket Elevators

Bucket elevators are primarily responsible for vertically transporting raw materials (such as lime, gypsum, etc.) to subsequent processing equipment, achieving efficient transfer of raw materials.

2. Batching and mixing

Batching and mixing are key to turning pre-treated raw materials into uniform slurry. Treated dry materials like cement and lime are quantitatively conveyed via metering equipment per precise formulas, with an error ≤±1%; aluminum powder slurry and grinding head waste slurry are added for resource utilization.

After entering the mixer, raw materials become flowing, uniform slurry through high-speed stirring. Stirring time and intensity must be controlled for full dispersion and to prevent premature bubble escape from over-stirring. The final slurry needs proper consistency and fluidity to stabilize subsequent pouring and foaming, ensuring uniform block pores and consistent performance.

screw conveyor

Mixer

metering tank

aluminum powder automatic quantitative feeding device

Screw conveyor

It transports dry materials such as cement, lime, fly ash, etc. stored in the silo to the metering device. The conveying volume can be adjusted to ensure that the raw materials enter the batching link as needed.

Metering tank

Metering tank includes mud metering tank, dry material metering scale, etc.. Different raw materials correspond to different metering tools. Cement, lime, fly ash and waste slurry are quantified strictly according to the formula ratio.

Mixer

After the measured raw materials are fed into the mixer, they are fully blended in the mixer to form a uniform and flowing slurry. The mixer must have strong stirring capacity to ensure that the raw materials are mixed evenly in a short time.

Aluminum powder feeding device

Aluminum powder serves as a foaming agent, and its addition accuracy directly determines the block’s pore structure and density (affecting lightweight and strength). The device achieves quantitative addition of aluminum powder slurry via automatic control.

3. Pouring and curing

Pouring and curing are critical to achieving the initial shape and porosity of the blocks. The mixed slurry is poured into the mold frame. The aluminum powder reacts with the alkaline material to release hydrogen, causing the slurry to expand and form a blank with uniform porosity.

After gas generation, the blank is cured at 50-70°C for 2-4 hours to harden for cutting. During this time, the blank continues to hydrate and solidify, preventing damage during demolding/cutting.

Pouring determines porosity and lightweight properties, while curing ensures strength and workability.

pouring machine

mold frame (including mold car)

static curing room

Pouring machine

The pouring machine accurately and evenly pours well-mixed slurry into the mold frame (or mold cart). Pouring volume and speed must be strictly controlled to ensure even slurry distribution in the mold frame, laying the foundation for subsequent gasification and expansion into a regular green body.

Mold frame

Mold frame (including mold cart) is the container for the slurry to expand and form the green body. The mold frame is used in conjunction with the mold cart to carry the slurry and move with the mold cart to the gas generation and resting ar

Static curing room

The resting chamber provides a stable temperature and humidity environment during the gassing and resting phases. A temperature control system precisely maintains the indoor temperature between 40°C and 70°C, ensuring a smooth gassing reaction.

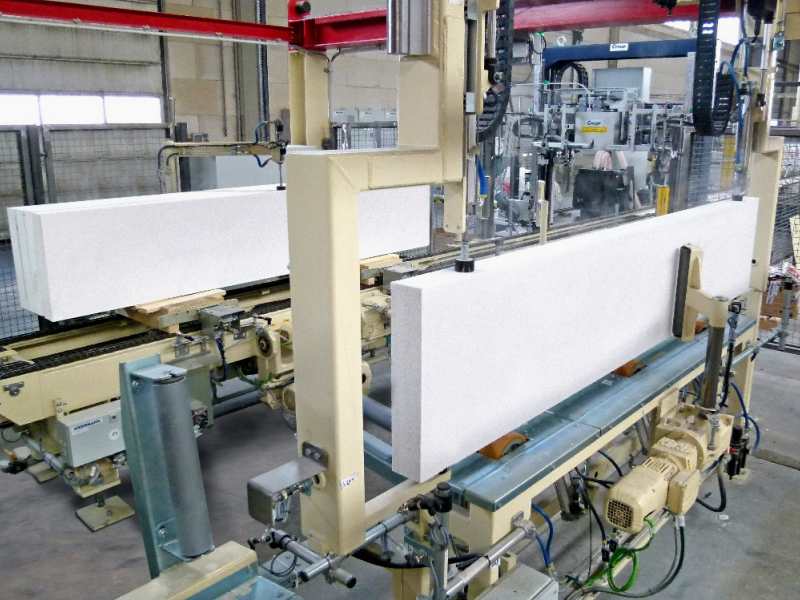

4. Cutting

The cutting process is key to processing the static-cured green body into standard sizes, determining block specifications, accuracy and appearance.

The green body with sufficient strength is transported to the cutting area, where multi-blade heads of the aerated concrete cutting machine work together for horizontal and vertical cutting, dividing the large green body into standard blocks or plates.

Cutting quality affects subsequent autoclaving and curing pass rates, serving as the core process to ensure uniform block specifications and construction applicability.

Aerated concrete cutting machine

blank transfer equipment

waste recycling equipment

formwork/base plate

positioning device

dust removal equipment

Aerated concrete cutting machine

The cutting machine is equipped with multiple sets of horizontal and vertical cutting heads that work together to cut the blank in the longitudinal, transverse, and horizontal directions, accurately dividing large blanks into blocks or panels of a set size. The cutting size and speed are adjustable.

Blank transfer equipment

Blank transfer equipment: including shuttles, tractors, etc., responsible for smoothly transferring the blanks (together with the mold frame or base plate) after they have stopped to the cutting machine, and transferring the cut blanks to the next process after cutting.

Frame/base plate

Frame/base plate: The blank is still placed on the frame or base plate during cutting, which provides stable support for the blank to prevent deformation or tipping during cutting.

Dust removal equipment

Dust removal equipment: Dust will be generated during the cutting process. Dust removal equipment (such as bag dust collectors and vacuum cleaners) can absorb the dust in time, improve the working environment, and prevent dust from adhering to the equipment and affecting its normal operation.

5. Autoclave curing

Autoclave curing is a key step in the formation of the final performance of the block. It promotes physical and chemical reactions in the green body through high temperature and high pressure.

After curing, the strength of the block reaches more than 90% of the design value, and it has the characteristics of light weight and heat insulation. It is the core process that determines its final quality.

autoclave

steam curing car

steam pipeline system

boiler

control system

blank stacking auxiliary

Autoclave

The autoclave is key to achieving a high-temperature, high-pressure curing environment. It can contain the block in a sealed container and withstand temperatures of 170-200°C and pressures of 0.8-1.5 MPa. Its sealing performance and pressure resistance determine the ultimate strength of the block.

Boiler

The boiler provides the saturated steam required by the autoclave and is the core equipment for energy supply. The boiler’s steam output, pressure, and quality (such as dryness) must be precisely matched to the autoclave’s needs.

Steam curing car

As the carrier and transporter for the green bodies, the curing cart is directly related to curing stability. It must be heat-resistant, load-bearing, and precisely aligned with the track to ensure the green bodies are neatly stacked and evenly stressed within the autoclave, ensuring efficient steam flow.

Control system

The control system uses temperature sensors, pressure sensors, and a PLC control cabinet to monitor and precisely control the temperature and pressure parameters, as well as the rate of increase or decrease, within the autoclave in real time. This prevents temperature and pressure fluctuations caused by manual operation errors.

6. Finished product stacking and inspection

Finished product stacking and inspection are the final steps in the production line, crucial for ensuring quality control and distribution standards.

After the blocks cool after steaming, quality inspectors conduct random or full inspections based on standard criteria for size, appearance, density, strength, and other factors, eliminating substandard products to ensure they meet usage requirements.

inspection tools

stacking equipment

handling equipment

Auxiliary facilities

Inspection tools

Inspection tools: Tape measures, calipers and other dimensional tools detect block length, width, height and deviation. Lighting equipment aids appearance checks for cracks, missing corners, etc. Pressure testing machines, density meters and other special instruments accurately evaluate physical properties like density and strength.

Stacking equipment

Stacking equipment includes pallets, racks, and palletizers. Pallets carry blocks and facilitate handling by forklifts and other equipment. Racks store blocks in layers. Palletizers automate the stacking of blocks.

Handling equipment

Handling equipment: such as forklifts and tractors, used to transport qualified blocks from the inspection area to the stacking site, or to adjust the position of blocks in the stacking site.

Auxiliary facilities

Auxiliary facilities includes rain shelters, moisture-proof mats, etc., used to protect blocks from rain and moisture. Various identification plates, used to mark the specifications, batches, production dates and inspection status of blocks, etc.

A leading manufacturer in the AAC block plant industry

Provide customized solutions and turnkey projects!

Learn moreBest AAC Block Manufacturing Plant manufacturer

As a professional manufacturer of AAC block/panel plant, We provide manufacturing lines with an annual output of 30,000 to 600,000m³/year. With semi-automatic type and fully automatic type.

We have exported to Southeast Asia, the Middle East, Africa, Europe, etc.

20+ years of professional experience

Exports to 50+ countries

Global EPC 100+ projects

Award-winning projects

CE/ISO/ASME certifications

Why choose us

Benefits of Our AAC Manufacturing Line

The product is lightweight, high-strength, heat-insulating and fire-resistant, suitable for multiple scenarios, and efficient in construction.

It is available in large, medium and small sizes, with flexible production capacity, and can be selected or upgraded as needed. 3. The raw materials are mainly solid waste, with a utilization rate of over 95% and low cost.

The raw materials are mainly solid waste, with a utilization rate of over 95% and low cost.

It meets environmental protection standards, has complete safety devices, and is in line with sustainable development.

The medium and large lines have a high degree of automation, precise control of differences, and stable products.

Why choose us

Application of AAC Block

Residential: High-rise infill walls, villa exterior walls, interior partition walls.

Commercial: Shopping malls, hotels, hospitals, schools.

Industrial: Factory enclosures, thermal insulation walls for cold storage.

Special: Fire walls, passive houses, prefabricated buildings, precast stairs/roof slabs.

Advantages of AAC Blocks

Lightweight and High-Strength

Thermal Insulation

Excellent Fire Resistance

Excellent Soundproofing

Easy Construction

Environmentally Friendly

Cases

Our latest projects

Our services

What we offer

Project Planning & Design

Provide overall planning and detailed design schemes for AAC block plants based on client needs and actual conditions, including process design, equipment layout, and civil engineering design.

Equipment Supply & Installation

Supply full sets of AAC production line equipment, and undertake installation and commissioning to ensure normal operation, meeting designed capacity and product quality standards.

Technical Training

Offer professional training for operators, technicians, and managers covering production processes, equipment operation, maintenance, and quality management.

After-Sales Service

Establish a sound after-sales system providing daily maintenance guidance, fault troubleshooting, and spare parts supply to ensure continuous stable production.

Testimonials

Stories From Our Clients

AAC Block Plant

20,000 Customer Reviews

20K

A very good AAC manufacturing plant manufacturer, our equipment has been running normally for 2 years, the manufacturer returns visits every week, a trustworthy partner

Name

Lisa

Our products

three types for your business

AAC Block Manufacturing Plant can be divided into three categories based on production scale: small, medium, and large. Their core differences lie in production capacity, equipment configuration, site requirements, investment costs, and applicable scenarios:

Small AAC Block Manufacturing Plant

Capacity: 30000-100000 m3/year

Autoclave: 1-3 sets

Investment cost: $ 60000 – $ 300000

Factory: about 4000-10000m2

Types: semi-automatic/ fully automatic

Features: low initial investment, high flexibility, suitable for small batch and multi-specification production.

Medium-scale AAC Block Manufacturing Plant

Capacity: 100000-200000 m3/year

Autoclave: 4-8 sets

Investment cost: $ 200000-$ 1000000

Factory: 10000-20000m2

Types: fully automatic

Features: Stable production capacity, controllable costs, flexibility as well as large-scale production.

Large AAC Block Manufacturing Plant

Capacity: 200000-400000 m3/year

Autoclave: 8-12 sets

Investment: $1000000 – $3000000

Factory: more than 20000m2

Types: fully automatic

Features: Significant scale effect, high product consistency, suitable for standardized and mass production, and can quickly respond to large demands.

Cases